Efficient low-temperature gel breaker for polymer fracturing fluid and preparation method thereof

A technology of fracturing fluid and gel breaker, which is applied in the direction of drilling compositions, chemical instruments and methods, etc., and can solve problems such as failure of gel breaker and reduction of peroxide gel breaking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

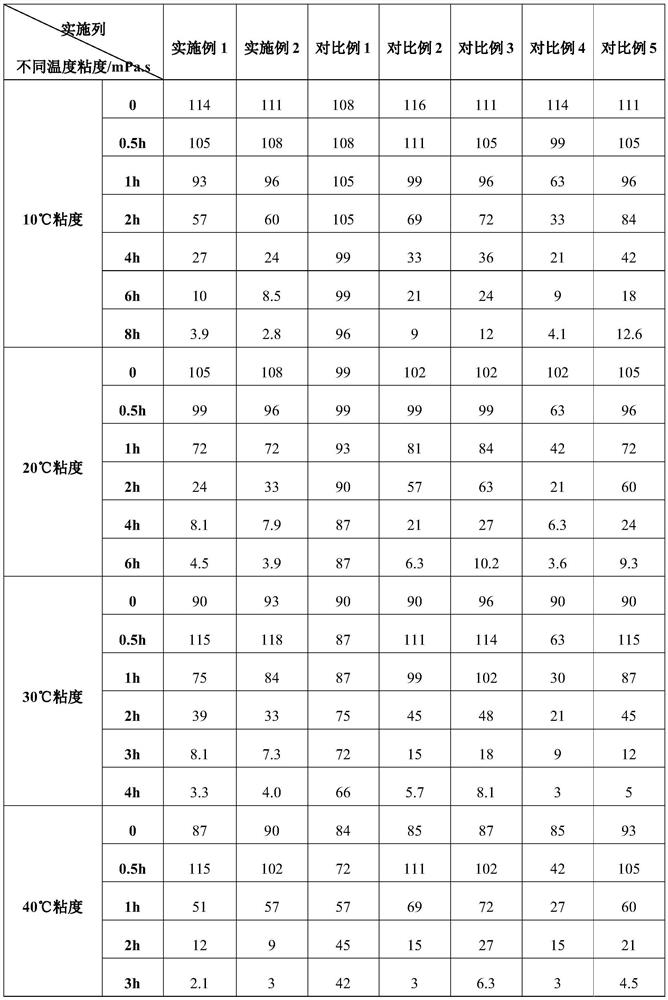

Examples

Embodiment 1

[0032] A high-efficiency low-temperature gel breaker for polymer fracturing fluid, including agent A and agent B. Calculated in parts by weight, agent A contains the following components: 35 parts of gel breaker main agent, 3 parts of gel breaker main agent stabilizer, 60.7 1 part of mineral oil, 1 part of polyamide, 0.3 part of hydrogenated castor oil; Agent B contains the following components: 10 parts of gel breaking activator, 2 parts of activation stabilizer, 15 parts of gel breaking auxiliary agent, 5 parts of gel breaking retarder, 3 parts part emulsifier, 40 parts white oil and 25 parts water.

[0033] In this embodiment, the gel-breaking main agent is potassium monopersulfate, the gel-breaking main agent stabilizer is acetic acid and EDTA (ethylenediaminetetraacetic acid) with a mass ratio of 1:1, and the gel-breaking activator is zinc chloride. The stabilizer is sodium nitrilotriacetate, the gel breaker auxiliary agent is sodium hypophosphite, the gel break retarder ...

Embodiment 2

[0039]A high-efficiency low-temperature gel breaker for polymer fracturing fluid, including agent A and agent B. Calculated in parts by weight, agent A contains the following components: 45 parts of gel breaker main agent, 5 parts of gel breaker main agent stabilizer, 47.5 parts Parts of mineral oil, 2 parts of polyamide, 0.5 part of hydrogenated castor oil; agent B contains the following components: 5 parts of gel breaking activator, 1 part of activation stabilizer, 20 parts of gel breaking auxiliary agent, 10 parts of gel breaking retarder, 5 parts part emulsifier, 30 parts white oil and 29 parts water.

[0040] In this embodiment, the gel-breaking main agent is potassium monopersulfate, the gel-breaking main agent stabilizer is citric acid and EDTA with a mass ratio of 1:1, the gel-breaking activator is zinc chloride, and the activation stabilizer is double 1, Sodium 6-hexamethylenetriaminepentamethylene phosphonate, the gel breaker auxiliary agent is sodium hypophosphite, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com