Embedded column base joint

A technology of embedded column feet and joints, which is applied in the direction of basic structure engineering, architecture, building construction, etc., can solve the problem of the limited buried depth of the foundation cap, the influence of the space used on the ground floor of the building, and the inability to meet the calculation requirements of embedded column feet and other problems, to achieve the effect of eliminating the workload, improving the force form of the column foot, and increasing the height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

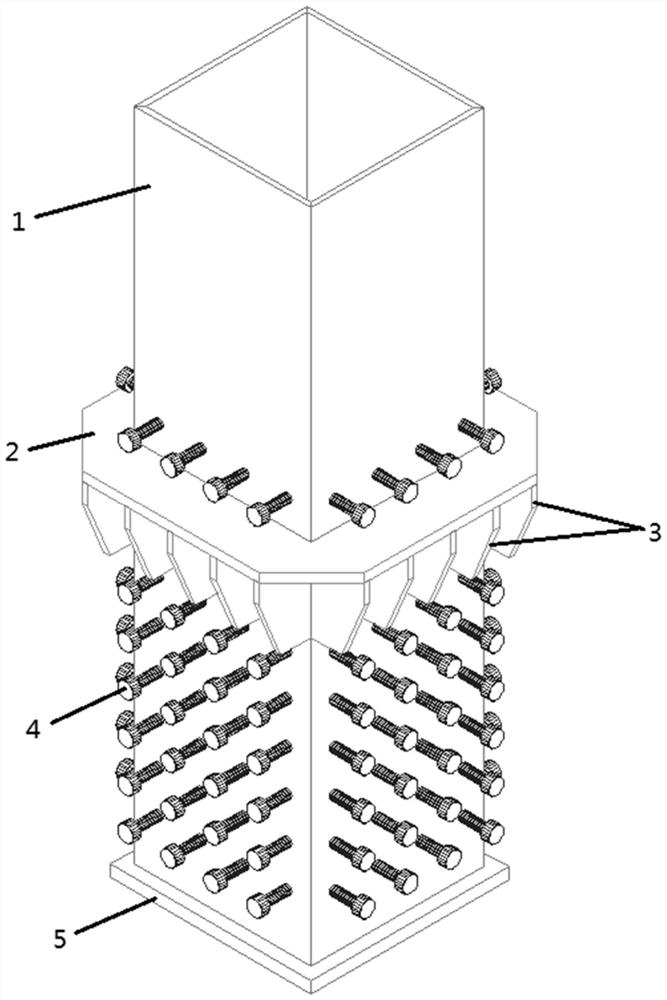

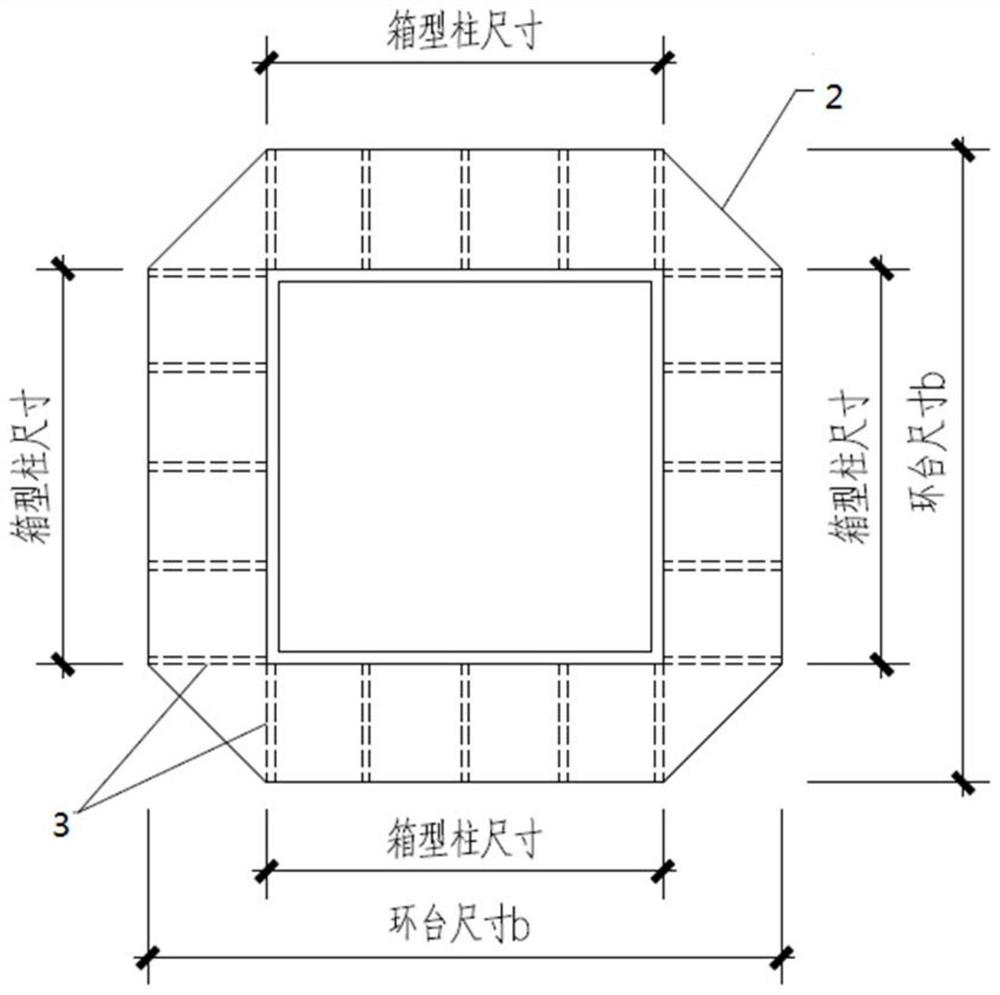

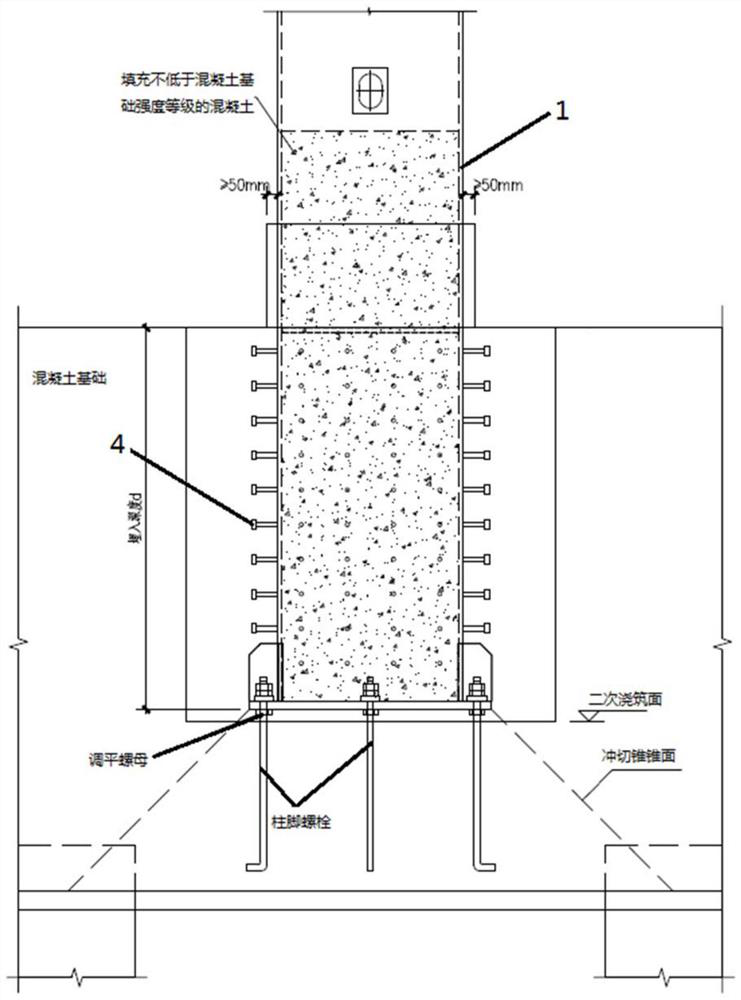

[0028] In the prior art, the form of the column base is as image 3 As shown, the bottom of the steel pipe column 1 is provided with a bottom plate 5. The steel pipe column 1 is a box-shaped column, and the box-shaped column is filled with concrete not lower than the strength level of the concrete foundation. The box-shaped column is inserted vertically in the concrete foundation. A stud 4 is provided on the column of the box column in the concrete foundation for resisting shear force. The cone surface of the punching cone is as image 3 As shown by the dotted line in the middle, at the bottom plate 5 of the steel pipe column 1 , in order to meet the load-bearing requirements, column foot bolts are installed on the bottom plate 5 . The transmission path of the force is as follows: part of the force is transmitted to the bottom plate 5 within the range of the column body, and then transmitted to the lower part of the concrete foundation, and the other part is transmitted to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com