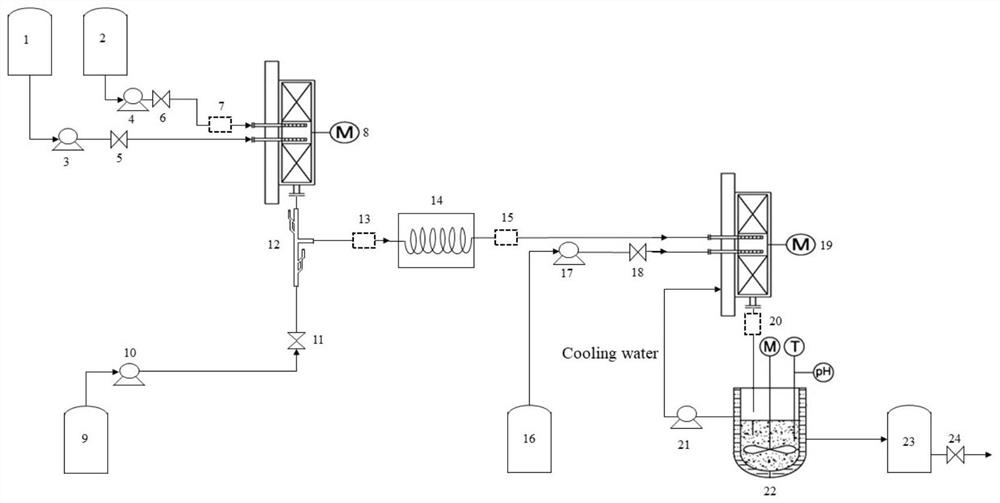

Continuous production system of nano disperse dyes

A nano-dispersion and production system technology, applied in the direction of organic dyes, azo dyes, monoazo dyes, etc., can solve the problems of large differences in dye batches, inconvenient application of post-treatment agents, and large particle sizes of dyes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

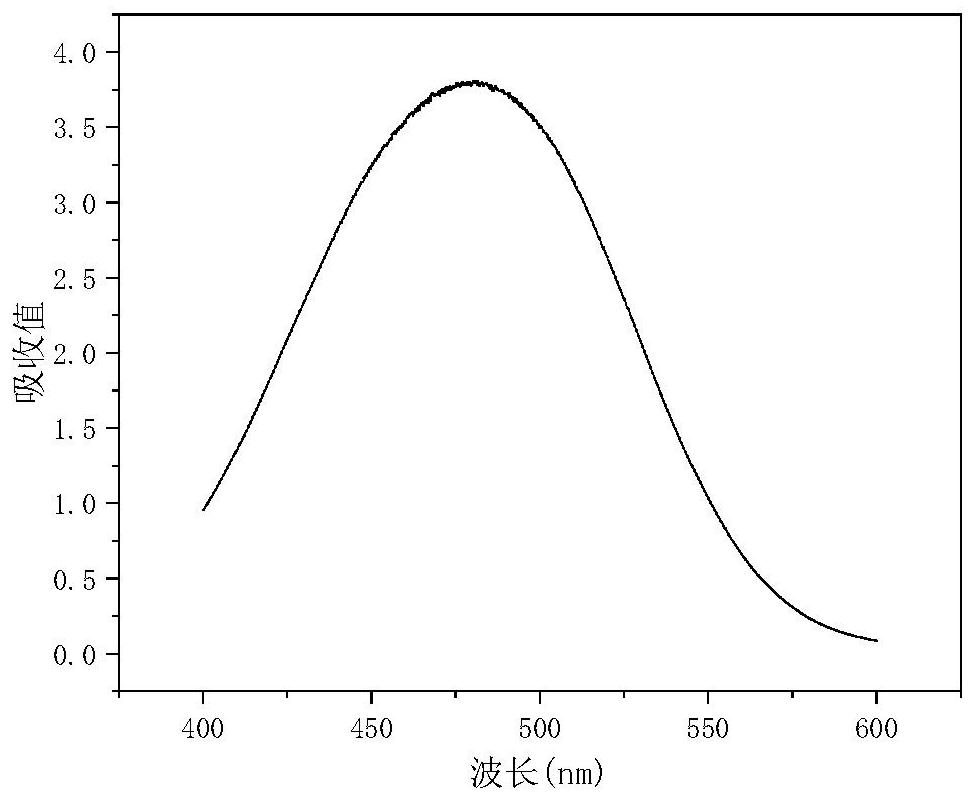

[0082] Example 1 A kind of continuous production of azo nano-disperse dyes

[0083] In this embodiment, the diazo component includes p-nitroaniline and nitrite, the diazotization reagent includes hydrochloric acid, and the coupling component includes N-ethyl-N-cyanoethylaniline and acetic acid.

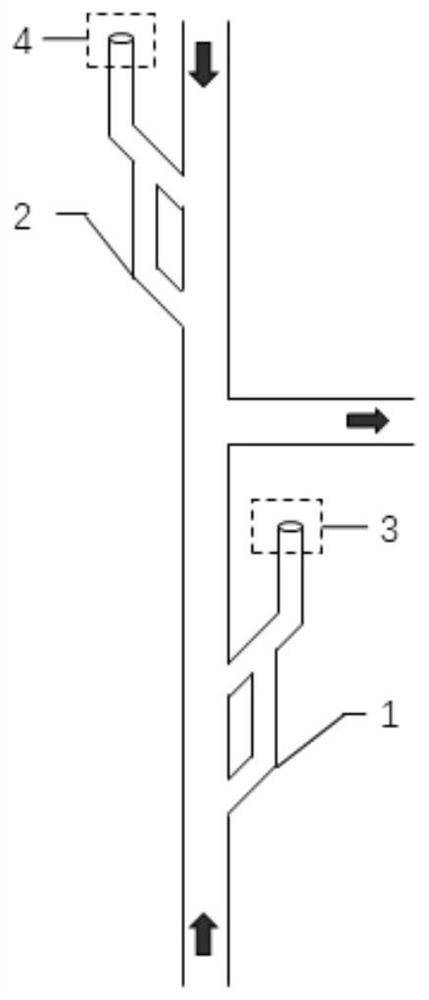

[0084] The diazotization reaction process is: premix the p-nitroaniline and nitrite mixture with hydrochloric acid solution through the premixing component, such as figure 2 shown, and then continuously fed into the spiral coil reactor through the pipeline to obtain the diazonium salt solution or suspension. The diazotization reaction is carried out at -5°C to 30°C, preferably 5°C to 10°C. The molar ratio of hydrogen ions of diazotization reaction hydrochloric acid to p-nitroaniline is Preferably 2.8:1, the molar ratio of sodium nitrite to p-nitroaniline is 1-2:1, preferably 1.07:1, and the feed flow rate is 50-300mL / min, preferably 50-120mL / min.

[0085] The coupling reaction pro...

example 2

[0094] A kind of continuous preparation method of example 2 nanoscale disperse dyes

[0095] In this embodiment, the diazo component includes p-nitroaniline and nitrite, the diazotization reagent includes hydrochloric acid, and the coupling component includes N-ethyl-N-cyanoethylaniline, acetic acid and Dispersant.

[0096] A method for preparing continuous nanometer disperse dyes using supergravity, characterized in that the method comprises the steps of:

[0097] The diazotization reaction process is: premix the p-nitroaniline and nitrite mixture with hydrochloric acid solution through the premixing component, such as figure 2 shown, and then continuously fed into the spiral coil reactor through the pipeline to obtain the diazonium salt solution or suspension. The diazotization reaction is carried out at -5°C to 30°C, preferably 5°C to 10°C. The molar ratio of hydrogen ions of diazotization reaction hydrochloric acid to p-nitroaniline is Preferably 2.8:1, the molar rati...

example 3

[0101] A kind of continuous preparation method of example 3 nanoscale disperse dyes

[0102] In this embodiment, the diazo component includes p-nitroaniline and nitrite, the diazotization reagent includes hydrochloric acid, and the coupling component includes N-ethyl-N-cyanoethylaniline, acetic acid and Dispersant.

[0103] A method for preparing continuous nanometer disperse dyes using supergravity, characterized in that the method comprises the steps of:

[0104] The diazotization reaction process is: premix the p-nitroaniline and nitrite mixture with hydrochloric acid solution through the premixing component, such as figure 2 shown, and then continuously fed into the spiral coil reactor through the pipeline to obtain the diazonium salt solution or suspension. The diazotization reaction is carried out at -5°C to +30°C, preferably 5°C to 10°C. The molar ratio of hydrogen ions of hydrochloric acid to p-nitroaniline in diazotization reaction is Preferably 2.8:1, the molar ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com