Preparation process of raw ore gold oil drop Jianzhan teacup

A preparation process, gold oil technology, which is applied in the field of preparation process of raw ore gold oil drop built lamps, can solve the problems of difficult cleaning, discoloration and blackening, etc., and achieve the effects of easy control, high yield and few defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

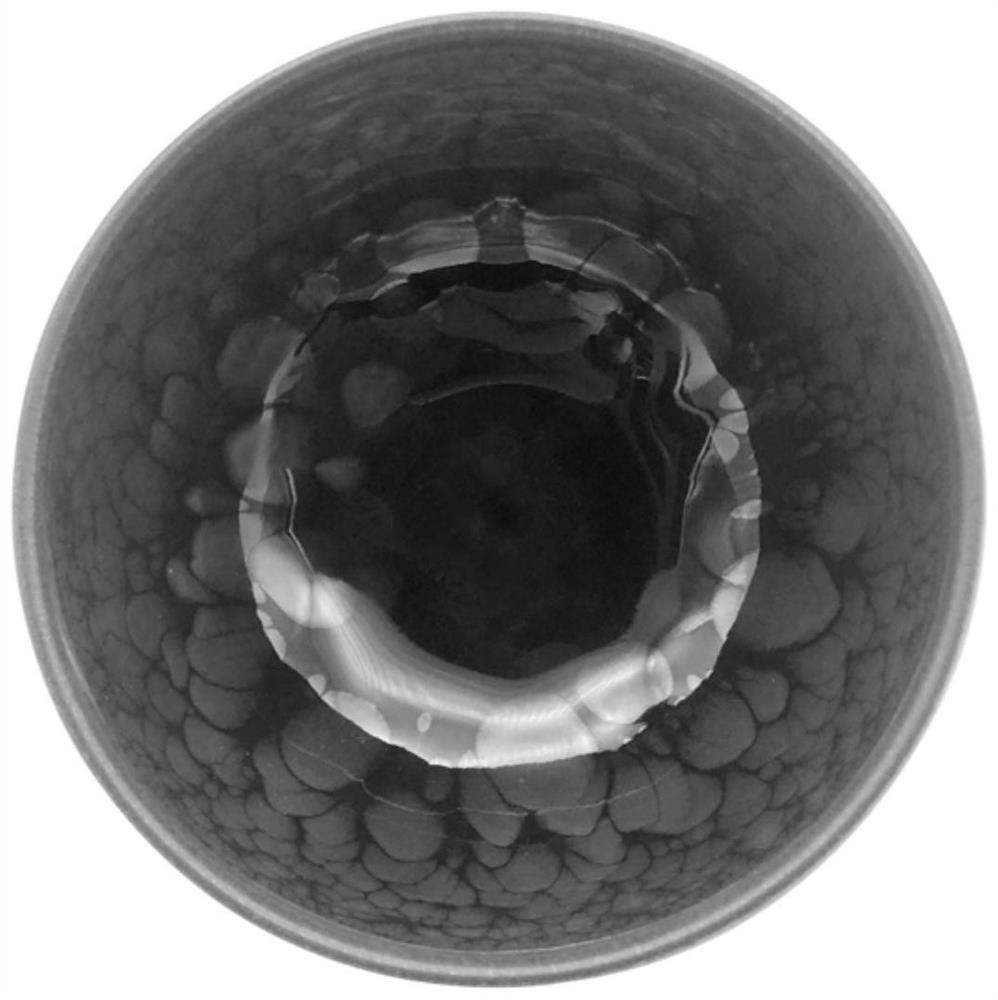

Image

Examples

Embodiment 1

[0043]The preparation process of the original mine oil droplets, including the following steps:

[0044](1) Preparation of the blank and glazed pulp, where

[0045]The blank is prepared by the following method: 1 parts by weight of red soil, 1 parts by weight of the loess mix, pulverize, washed, filter, refined mud, agonized, to obtain the sock; Sliding blank, killing, vegetarian, cooled, gave a billet;

[0046]The step (1) is burned into a kiln temperature of 6 hours from constant temperature to 800 ° C, stopped, cooled.

[0047]The glaze paste was prepared by the following method: 8 parts by weight of glaze, 0.8 parts by weight of grass ash, 1 parts by weight of potassium waith, 0.4 parts by weight of limestone, 0.3 parts by weight of talc, plus 1.3 weight of water Put it into the ball mill and grind, over 80 mesh sieve to get the glaze pulver;

[0048]The red soil is taken from Shuiji Town, Jianyang District, Nanping City, Nanping, Fujian Province; Nanlin Village, Jianyang District, Nanping Cit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com