Quantitative mixing and conveying device for 3D printing

A 3D printing and conveying device technology, applied in the field of 3D printing, can solve problems such as instability, easy solid-liquid separation of slurry, limited capacity of pneumatic extrusion barrel, etc., and achieve the effect of simplifying the mechanism structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to understand the characteristics and technical content of the present invention in more detail, the implementation of the present invention will be described in detail below in conjunction with the accompanying drawings. The attached drawings are only for reference and description, and are not intended to limit the present invention.

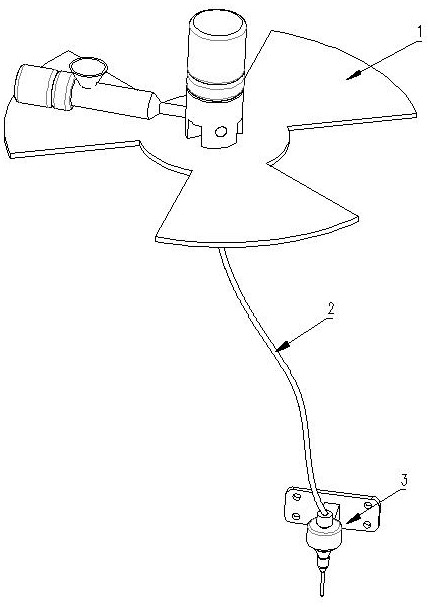

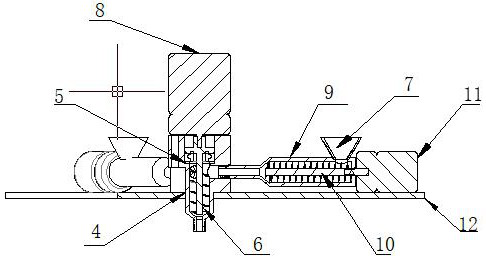

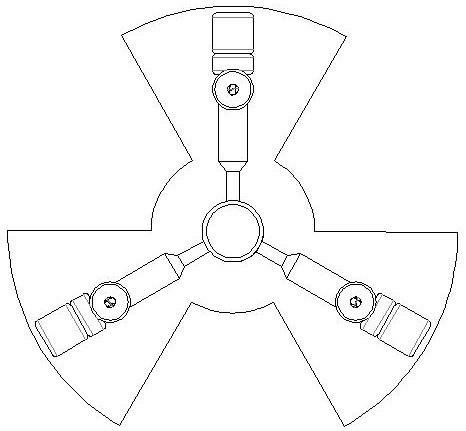

[0032] refer to Figure 1-5 A quantitative mixing and conveying device for 3D printing, comprising: a mixing feeder 1, a mixing feeding conduit 2, and a needle extrusion nozzle 3; the mixing feeder 1 includes: a mixing feeding housing 4, a sealing gasket 5. Mixing feeding screw 6, mixing feeding motor 7, feeding port 8, quantitative feeding machine housing 9, quantitative feeding screw 10, quantitative feeding motor 11, mixer chassis 12; mixing feeding conduit 2 includes: conduit connector 13 , feeding conduit 14, feeding spring 15; needle extrusion nozzle 3 includes: connecting mechanism 16, extrusion screw 17, printing needle ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com