Environment-friendly plastic degradation equipment

An environmental protection and equipment technology, applied in the direction of solid separation, filter screen, grille, etc., can solve the problems of low work efficiency, inconvenient heating operation, inconvenient degradation operation, etc., to improve the melting speed, improve work efficiency, comprehensive The effect of stirring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

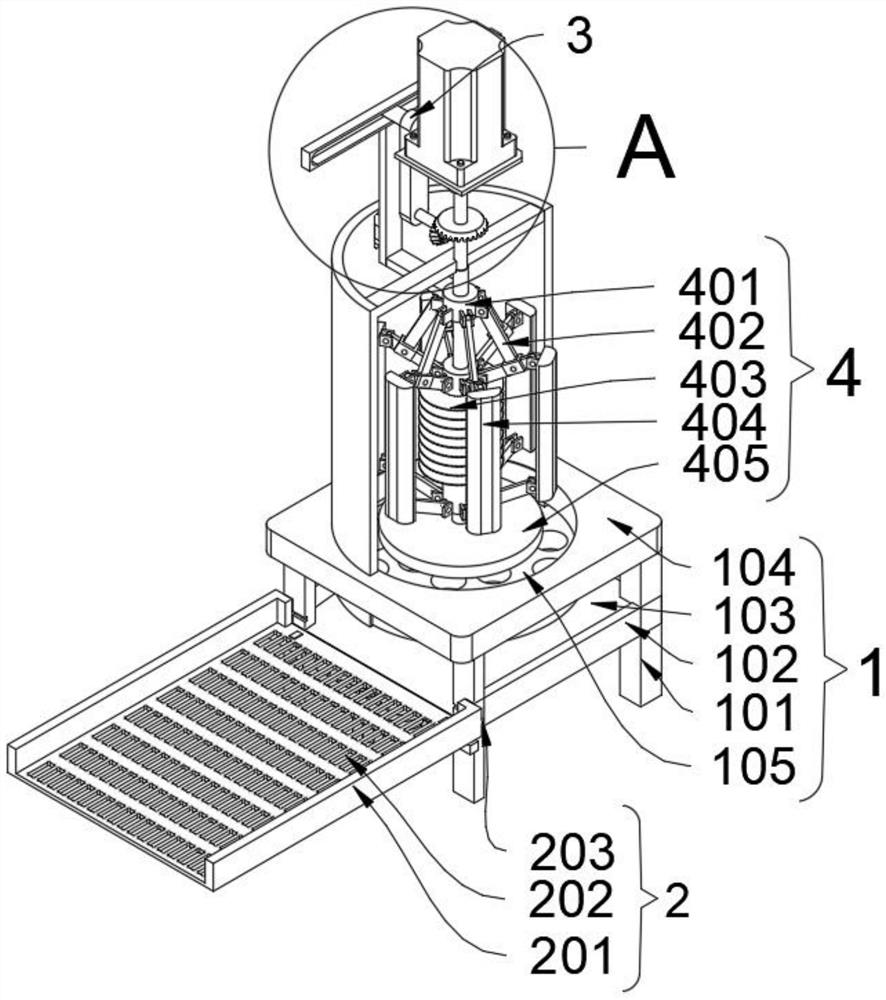

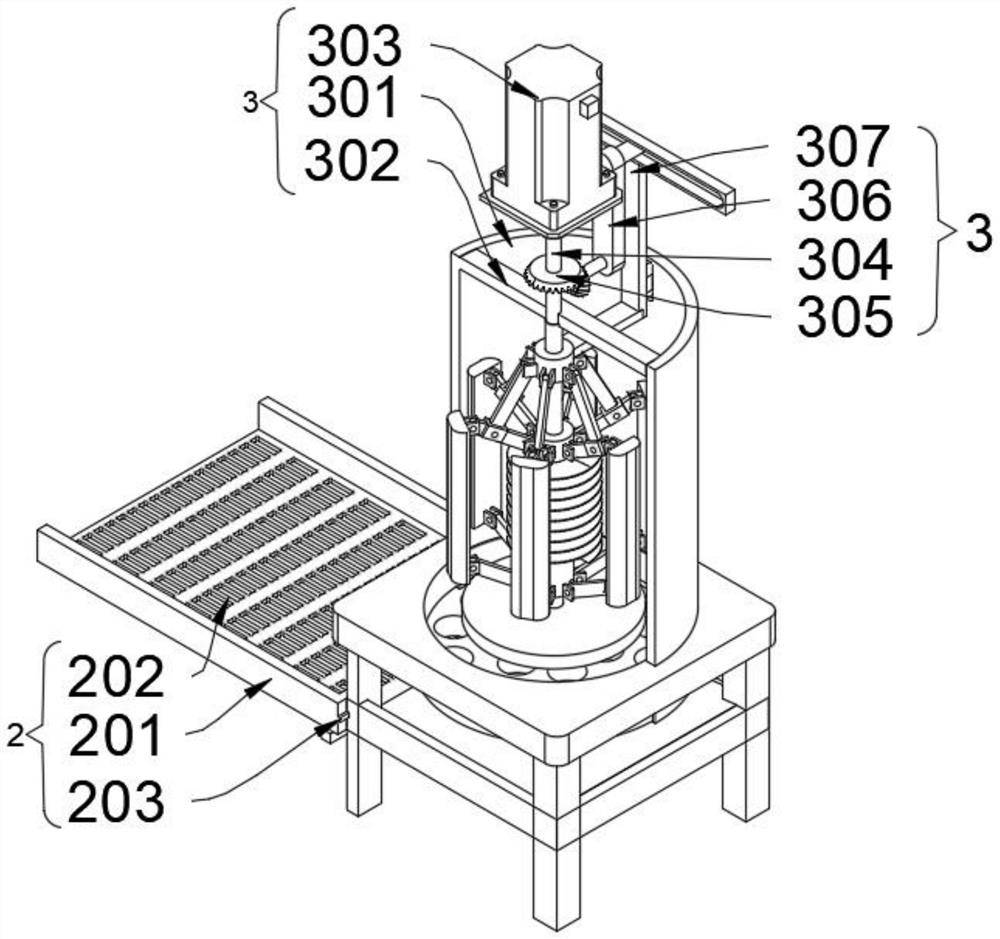

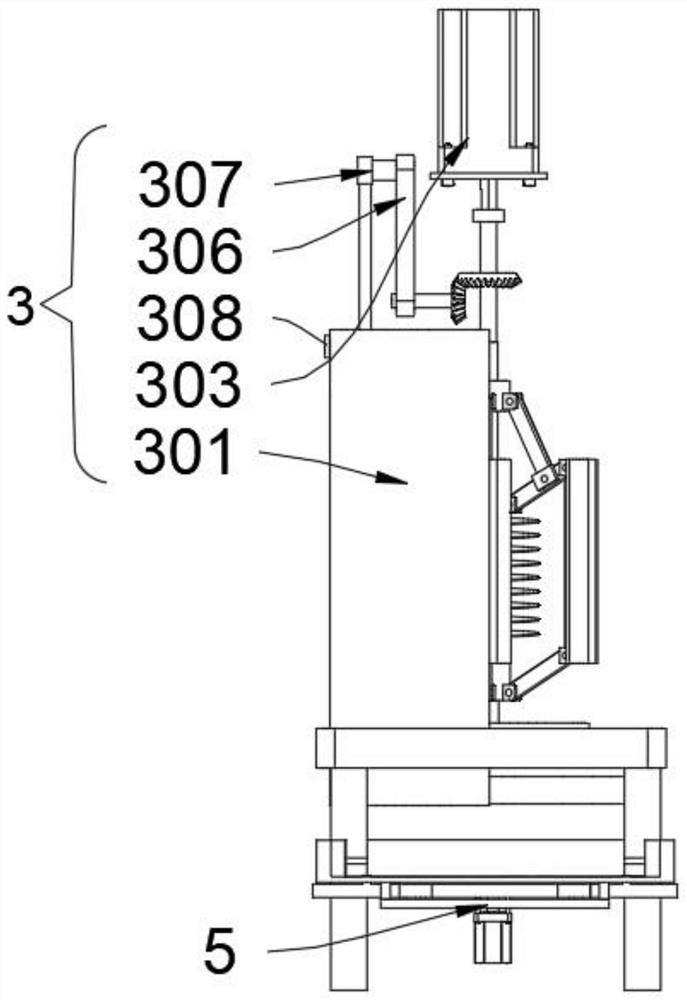

[0029] as attached figure 1 to attach Figure 6 Shown:

[0030] The present invention provides a plastic environmental protection degradation equipment, including: a screening mechanism 2 and a reciprocating stirring mechanism 4, the screening mechanism 2 is slidably connected to the left end of the guiding support mechanism 1, and the bottom end of the screening mechanism 2 is equipped with a reciprocating vibration Mechanism 5; the reciprocating stirring mechanism 4 is fixedly connected to the top position of the guiding support mechanism 1, and the top of the reciprocating stirring mechanism 4 is equipped with a driving mechanism 3; the reciprocating stirring mechanism 4 also includes stirring teeth 403, scraper plate 404 and pressing plate 405, The stirring tooth 403 is fixedly connected to the bottom end of the outer peripheral surface of the driving shaft 304. There are six scraper plates 404 in total, and the six scraper plates 404 are respectively connected to the six...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com