A rapid cooling device for chemical materials

A rapid cooling and material technology, used in household refrigeration devices, lighting and heating equipment, household appliances, etc., can solve the problems of low cooling and cooling efficiency, insufficient material cooling, etc., to achieve fast cooling speed, full and fast turning effect. cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

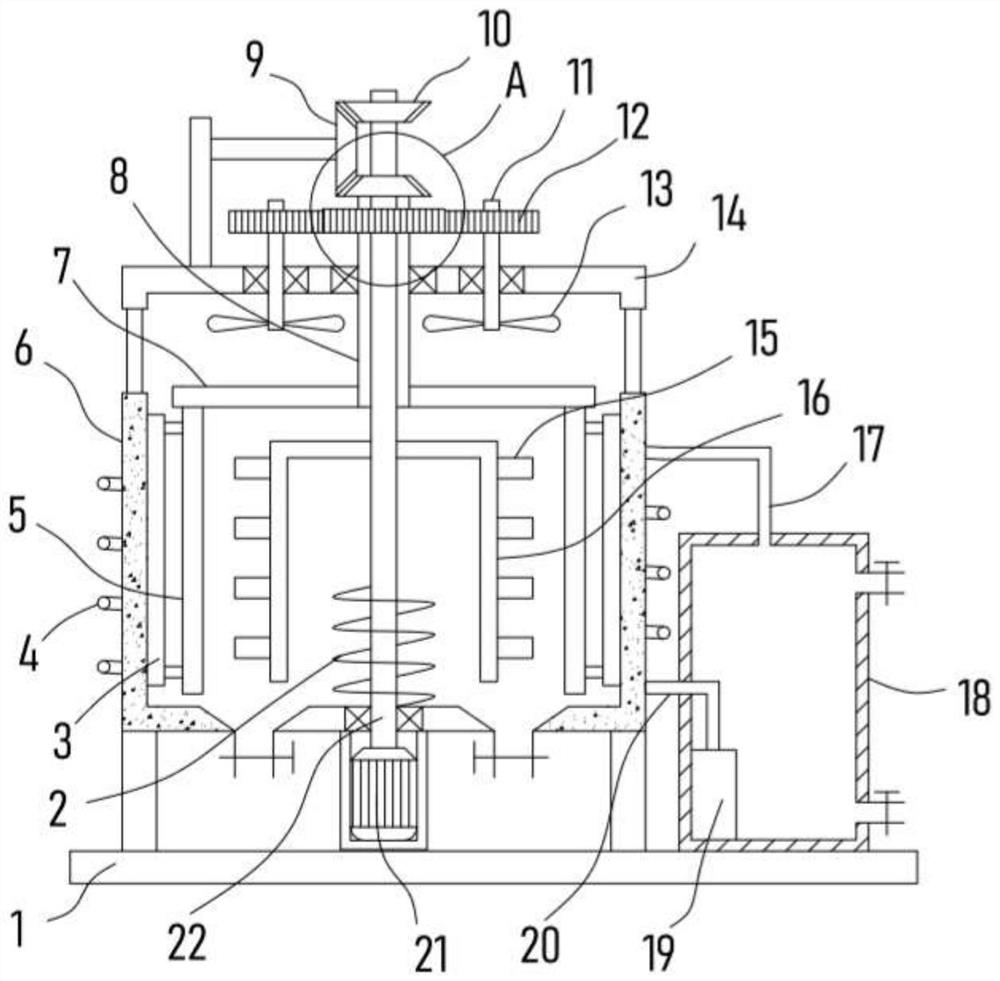

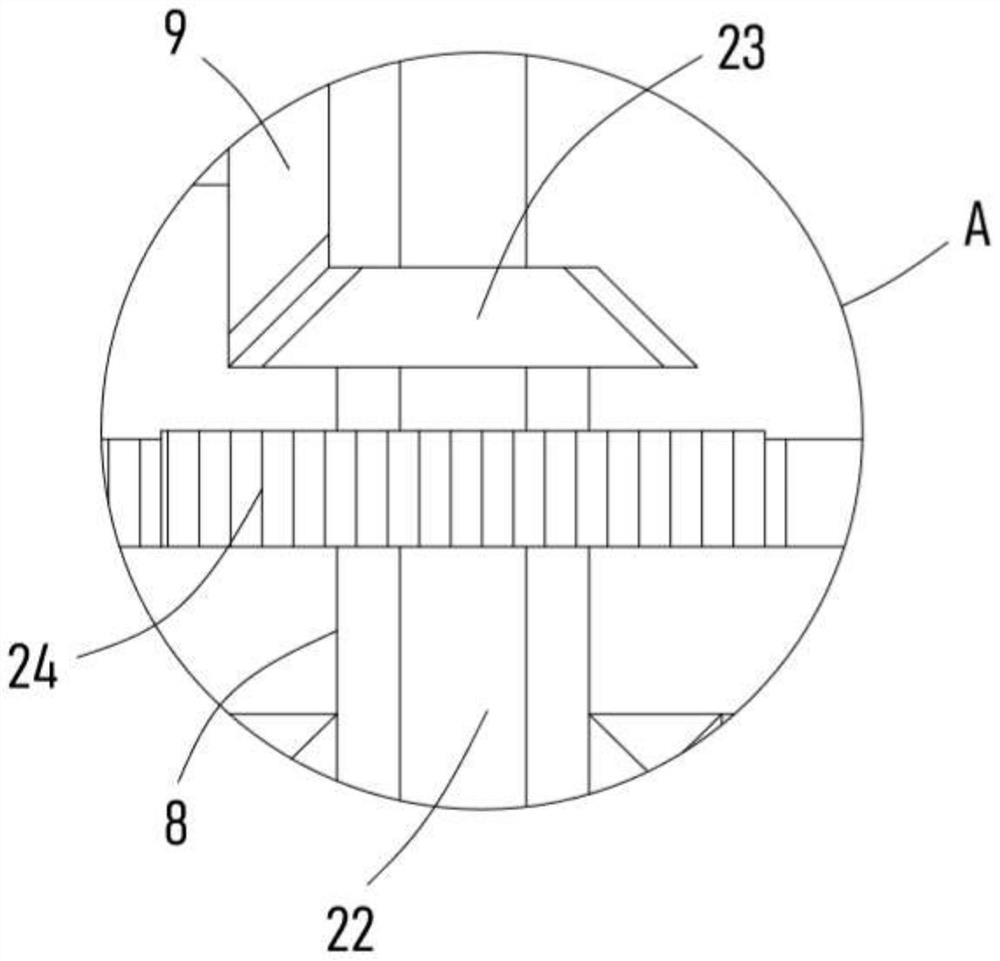

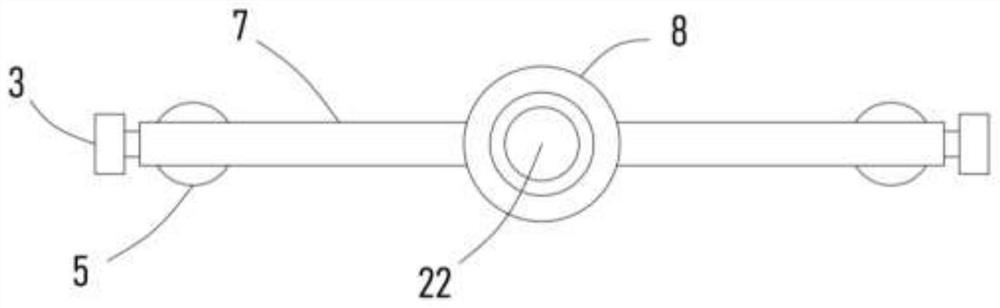

[0021] see Figure 1-3 , a chemical material rapid cooling device, comprising a support plate 1, a cooling barrel 6 is fixedly installed on the support plate 1, the cooling barrel 6 is an open structure, and the cooling barrel 6 is used to store the chemical materials to be cooled, and the cooling The barrel 6 is fixed with a fixed frame 14, the support plate 1 is fixedly installed with a drive motor 21, the output shaft of the drive motor 21 is coaxially fixed with a drive shaft 22 extending into the cooling barrel 6, and the side wall of the drive shaft 22 is fixed. The inner frame 16 is evenly fixed with several stirring teeth 15 on the inner frame 16 .

[0022] The drive motor 21 drives the drive shaft 22 to rotate, and the drive shaft 22 drives the inner frame 16 to rotate to realize the stirring of the chemical raw materials in the cooling barrel 6, and the fixed stirring teeth 15 on the inner frame 16 can further promote the chemical raw materials as the inner frame 16 ...

Embodiment 2

[0028] On the basis of Embodiment 1, in addition, the scraper 3 abutting against the inner wall of the cooling barrel 6 is fixedly installed on the side of the stirring rod 5 close to the inner wall of the cooling barrel 6, and the rotation of the stirring rod 5 drives the stirring rod 5 to the cooling barrel 6. The inner wall is scraped, which makes the mixing range of chemical materials wider and the heat dissipation effect is more sufficient.

[0029] Further, the surface of the driving shaft 22 is fixed with a screw blade 2, and the screw blade 2 is located inside the cooling barrel 6. The screw blade 2 is set to rotate with the driving shaft 22 and the chemical raw materials at the bottom of the cooling barrel 6 are spirally turned upwards, so that the chemical materials The heat dissipation effect is better.

[0030] Further, a cold water tank 18 located on one side of the cooling bucket 6 is fixedly installed on the support plate 1, and the cold water tank 18 is filled ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com