Wall perforating device for indoor decoration

A drilling device and interior decoration technology, which is applied to stone processing tools, work accessories, manufacturing tools, etc., can solve the problems of debris splashing, height adjustment, etc., and achieve the effect of saving energy, reducing work intensity, and facilitating drilling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

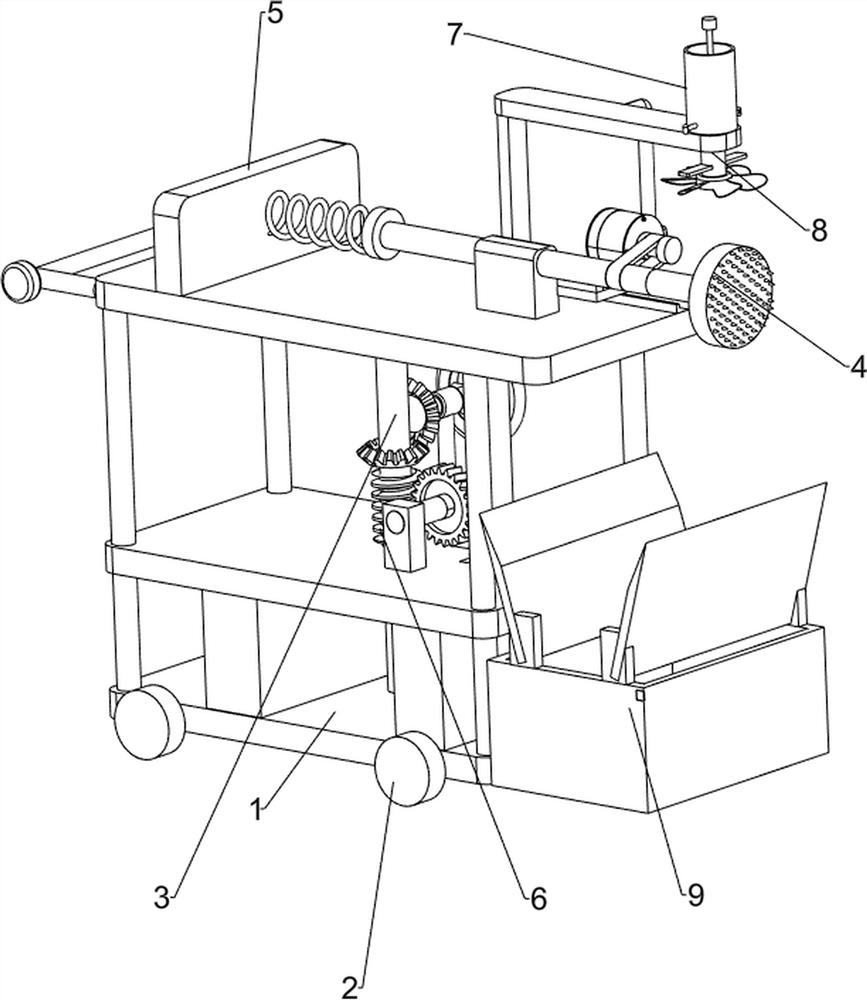

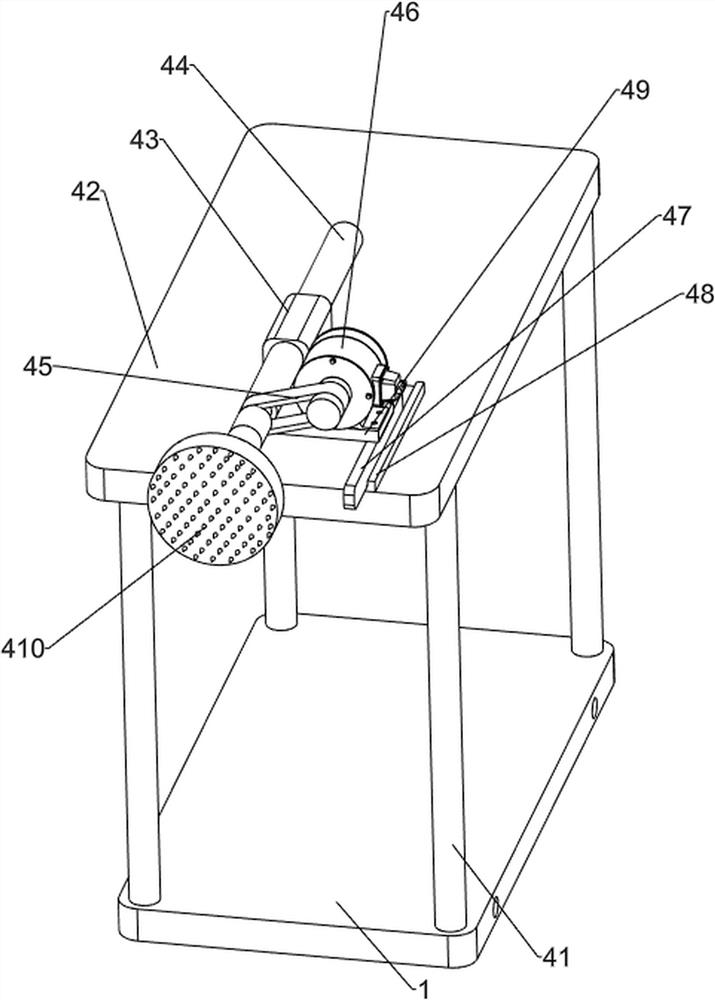

[0029] A wall punching device for interior decoration, such as Figure 1-Figure 3 As shown, it includes base plate 1, wheel 2, first support column 3, punching mechanism 4 and extruding mechanism 5, base plate 1 is provided with wheels 2 around, and the middle rotation type is provided with first support column 3 on base plate 1, base plate 1 is provided with a punching mechanism 4, and the left side of the punching mechanism 4 is provided with an extruding mechanism 5.

[0030] When it is necessary to use this equipment to punch holes, the extrusion mechanism 5 is manually pushed, and the extrusion mechanism 5 drives the wheels 2 to move to the wall, and then squeezes the punching mechanism 4 to punch holes on the wall. After the wall is punched, Manually pull the extruding mechanism 5 to move backward, so that the punching mechanism 4 leaves the wall and no longer punches holes. If the wall needs to be punched, the above steps are repeated.

[0031] The punching mechanism 4...

Embodiment 2

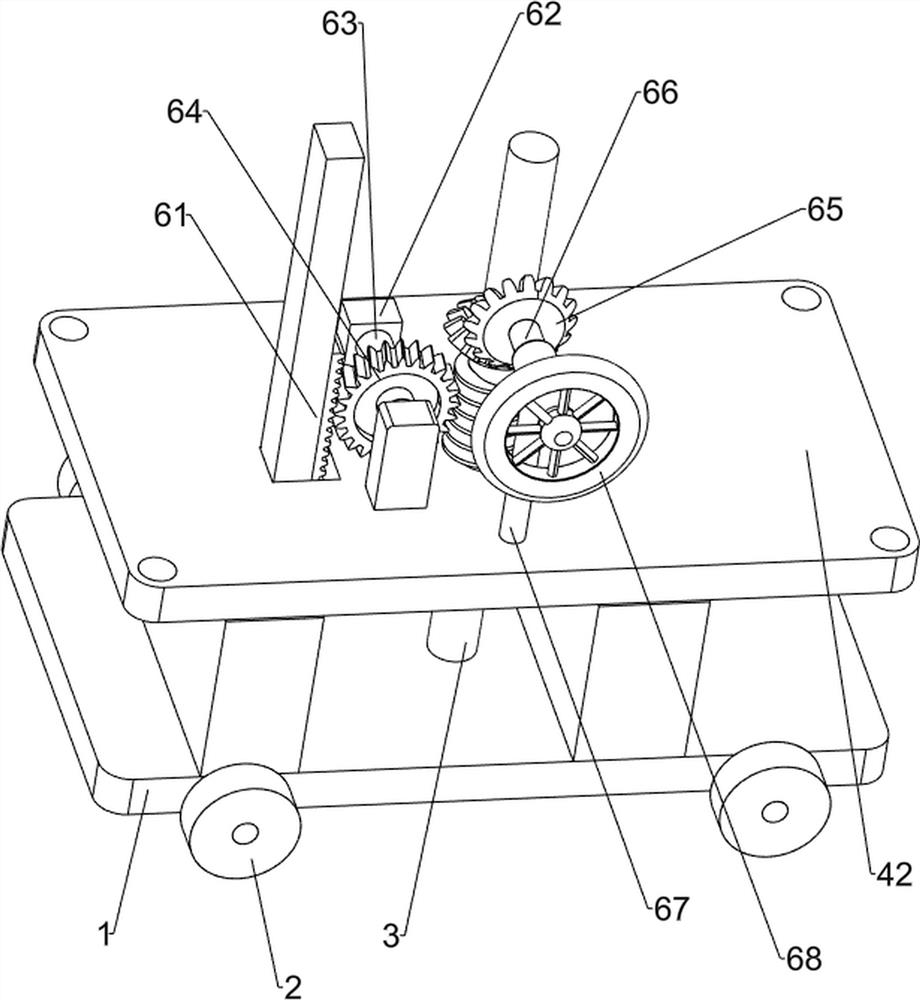

[0036] On the basis of Example 1, such as figure 1 , Figure 4-Figure 7 Shown, also comprise up and down mechanism 6, and up and down mechanism 6 comprises rack 61, the 3rd fixed post 62, the first rotating shaft 63, spur gear 64, bevel gear set 65, the second rotating shaft 66, the 4th fixed post 67 and the rotating disc 68, the right side of the middle panel 42 is provided with a rack 61, the panel 42 middle part is provided with a third fixed post 62, and the third fixed post 62 is provided with a first rotating shaft 63 for rotation. , the middle part of the first rotating shaft 63 is provided with a spur gear 64, the spur gear 64 meshes with the rack 61, the upper rear part of the panel 42 is provided with a fourth fixed post 67, and the fourth fixed post 67 is rotatably provided with a second rotating shaft 66 A bevel gear set 65 is provided between the front side of the second rotating shaft 66 and the first support column 3 , and a rotating disk 68 is provided at the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com