Tool internal welding spot detection device for duplexer machining

A solder joint detection and duplexer technology, which is applied in the field of solder joint detection devices inside a tooling for duplexer processing, can solve the problems of inseparability, low efficiency, time consumption, etc., to improve efficiency, improve stability, Achieving the effect of supporting capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

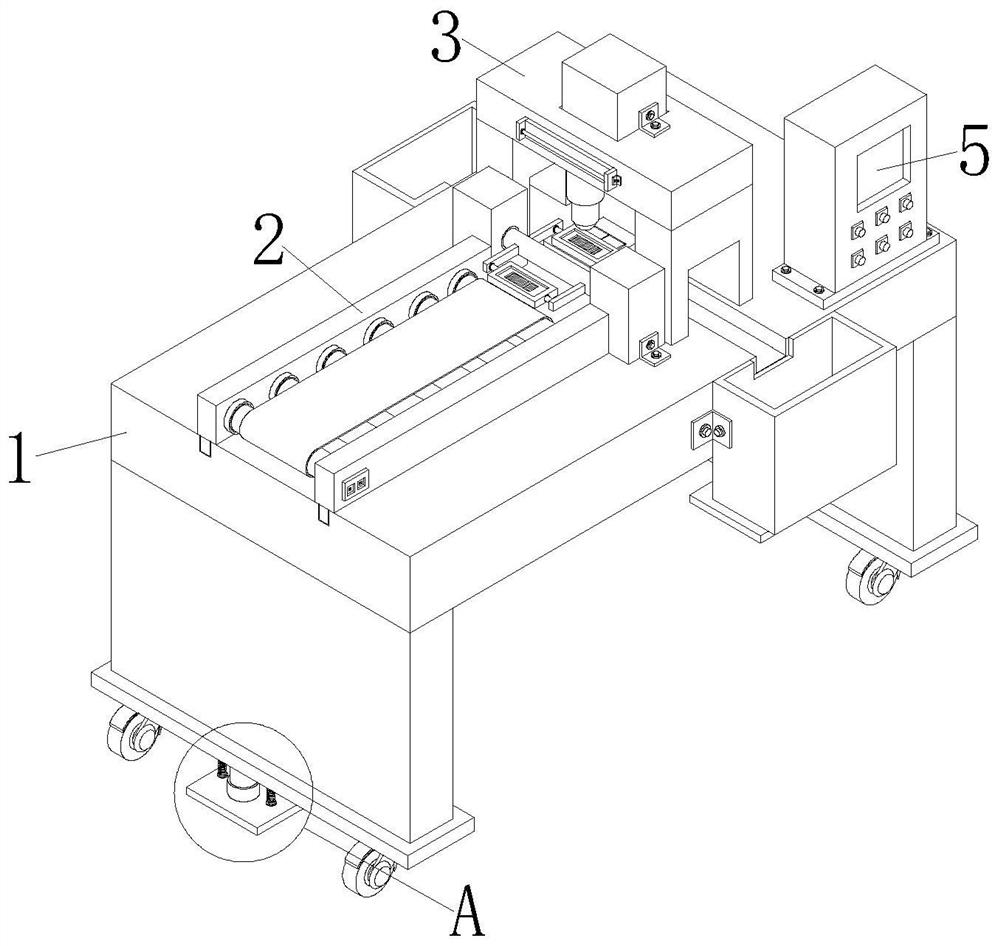

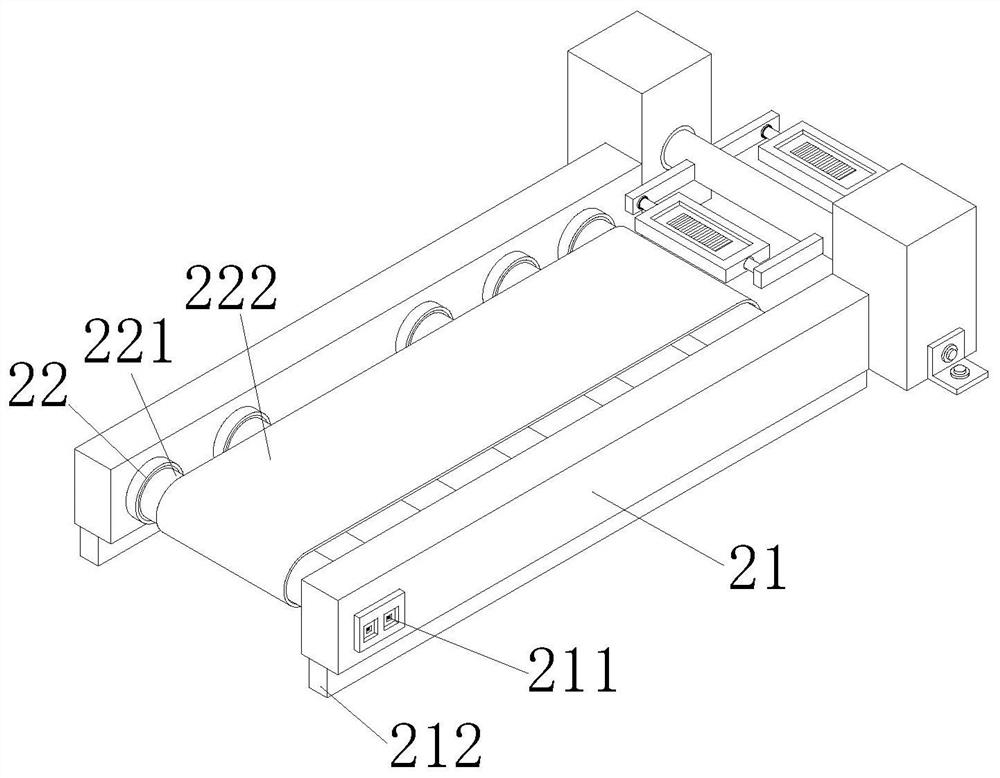

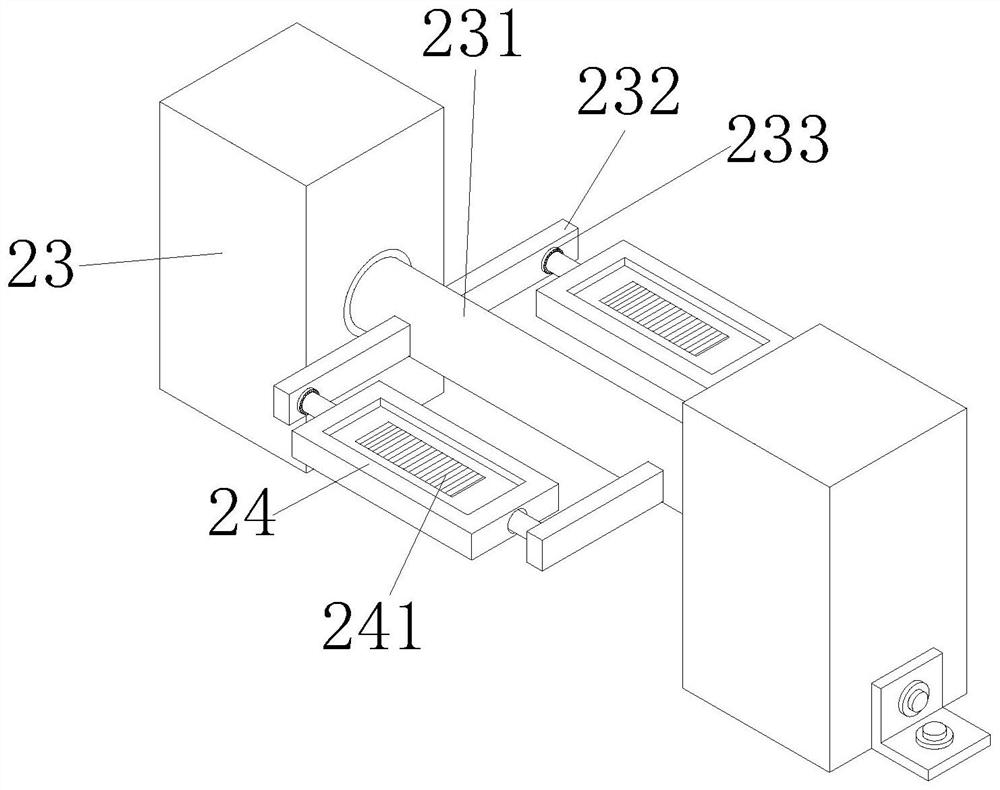

[0034] Embodiment one, please emphatically refer to the attached Figure 1-6 As shown, a device for detecting internal solder joints of a tooling used for duplexer processing includes a working platform 1, and a transmission device 2 is provided on one side of the upper surface of the working platform 1, and the transmission device 2 includes a rectangular transmission plate 21. Rectangular transmission plates 21 are symmetrically arranged on the upper surface of the working platform 1, and a plurality of sliding bearings 22 are arranged in parallel at equal intervals on one side of the inner wall of each of the rectangular transmission plates 21. Shafts 221, each transmission shaft 221 is provided with a conveyor belt 222, and a detector 3 is provided near the transmission device 2, the detector 3 includes a concave hole support module 31, and the concave hole support module 31 is symmetrical Set on one side of the upper surface of the working platform 1, each of the concave ...

Embodiment 2

[0035] Embodiment two, please emphatically refer to the attached figure 2 , 3 As shown in and 6, one side of the outer wall of one of the rectangular transmission plates 21 is provided with a power socket 211, through the power socket 211, the access to the power supply is realized, and the lower surface of each of the rectangular transmission plates 21 is provided with a rectangular bump 212, each of the rectangular protrusions 212 is connected to the rectangular slot 11 respectively, each of the rectangular slots 11 is arranged on both sides of the upper surface of the working platform 1, through the rectangular slot 11 and the rectangular protrusion 212 Fitting each other, the fixing of the rectangular transmission plate 21 is realized. The groove of each groove module 24 is provided with a friction pattern 241. Through the friction pattern 241, the maximum static friction force of the contact surface is increased to avoid the friction between the moving double Sliding occu...

Embodiment 3

[0036] Embodiment three, please emphatically refer to the attached Figure 4 , 5 As shown in and 6, a lighting assembly 36 is provided on one side of the support plate 32, and the lighting assembly 36 includes a recessed light frame 361, and one side of the outer wall of the recessed light frame 361 is connected to the support plate 32, and the recessed light frame 361 is connected to the support plate 32. Both sides of the inner wall of the grooved light frame 361 are symmetrically provided with lamp holders 362, each of said lamp holders 362 is provided with a lamp tube 363 at one end away from the inner wall of the grooved light frame 361, through the lighting assembly 36, the increase of the brightness of the detection environment is realized, which is convenient Detection, the lower surface of the rectangular moving module 41 is provided with a sliding module 43, a plurality of pulleys 431 are arranged in the groove of the sliding module 43, each of the pulleys 431 is con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com