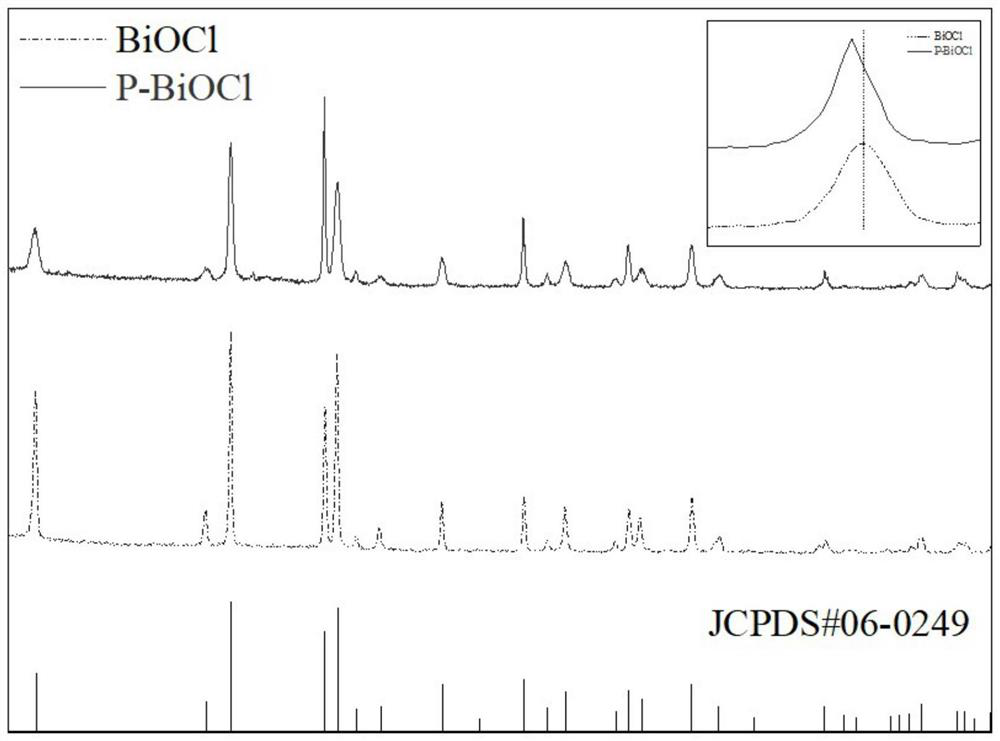

A kind of p-doped biocl visible light catalyst and preparation method thereof

A visible light and catalyst technology, applied in the direction of catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve the problems of unclear BiOCl, achieve enhanced visible light absorption range, good application prospects, and simple preparation process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] In this embodiment, a method for preparing a P-doped BiOCl visible light catalyst, in parts by weight, comprises the following steps:

[0042] (1) 2.425g of Bi(NO 3 ) 3 ·5H 2 0 was added in 40ml ethylene glycol, fully stirred to obtain a bismuth nitrate suspension; 0.37275g KCl was added to 10ml deionized water, stirred and dissolved to obtain a potassium chloride solution;

[0043] (2) Mix the bismuth nitrate suspension obtained in step (1) with potassium chloride solution, and add NaH 2 PO 2 ·H 2 After O is used as the phosphorus source, adjust the pH of the mixed solution to 3, stir at least 30min to the solution pH value no longer changes, as the reaction solution; wherein, the phosphorus source addition is based on the molar weight of its phosphorus element, Bi(NO 3 ) 3 ·5H 2 O:P=10:1;

[0044] (3) React the reaction solution obtained in step (2) at 180°C for 24 hours. After the time is up, cool it down to room temperature naturally, wash it with water and ...

Embodiment 2

[0047] In this embodiment, a method for preparing a P-doped BiOCl visible light catalyst, in parts by weight, comprises the following steps:

[0048] (1) 2.425g of Bi(NO 3 ) 3 ·5H 2 0 was added in 40ml ethylene glycol, fully stirred to obtain a bismuth nitrate suspension; 0.37275g KCl was added to 10ml deionized water, stirred and dissolved to obtain a potassium chloride solution;

[0049] (2) Mix the bismuth nitrate suspension obtained in step (1) with potassium chloride solution, and add NaH 2 PO 2 ·H 2 After O is used as the phosphorus source, adjust the pH of the mixed solution to 3, stir at least 30min to the solution pH value no longer changes, as the reaction solution; wherein, the phosphorus source addition is based on the molar weight of its phosphorus element, Bi(NO 3 ) 3 ·5H 2 O:P=20:1;

[0050] (3) React the reaction solution obtained in step (2) at 180°C for 24 hours. After the time is up, cool it down to room temperature naturally, wash it with water and ...

Embodiment 3

[0053] In this embodiment, a method for preparing a P-doped BiOCl visible light catalyst, in parts by weight, comprises the following steps:

[0054] (1) 2.425g of Bi(NO 3 ) 3 ·5H 2 0 was added in 40ml ethylene glycol, fully stirred to obtain a bismuth nitrate suspension; 0.37275g KCl was added to 10ml deionized water, stirred and dissolved to obtain a potassium chloride solution;

[0055] (2) Mix the bismuth nitrate suspension obtained in step (1) with potassium chloride solution, and add NaH 2 PO 2 ·H 2 After O is used as the phosphorus source, adjust the pH of the mixed solution to 3, stir at least 30min to the solution pH value no longer changes, as the reaction solution; wherein, the phosphorus source addition is based on the molar weight of its phosphorus element, Bi(NO 3 ) 3 ·5H 2 O:P=8:1;

[0056] (3) React the reaction solution obtained in step (2) at 180°C for 24 hours. After the time is up, cool it down to room temperature naturally, wash it with water and e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com