Waste gas treatment device for high-temperature retort pouch curing chamber

A waste gas treatment device and high-temperature cooking bag technology, which is applied in chemical/physical processes, transportation and packaging, chemical instruments and methods, etc., can solve problems such as polluting the environment, endangering human health, and exhaust gas cannot be efficiently treated

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

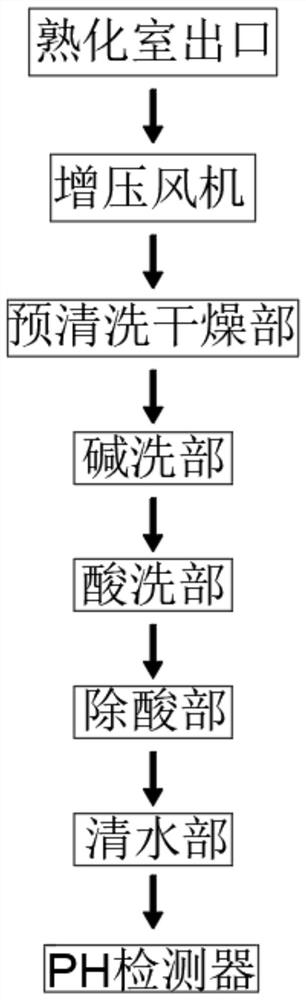

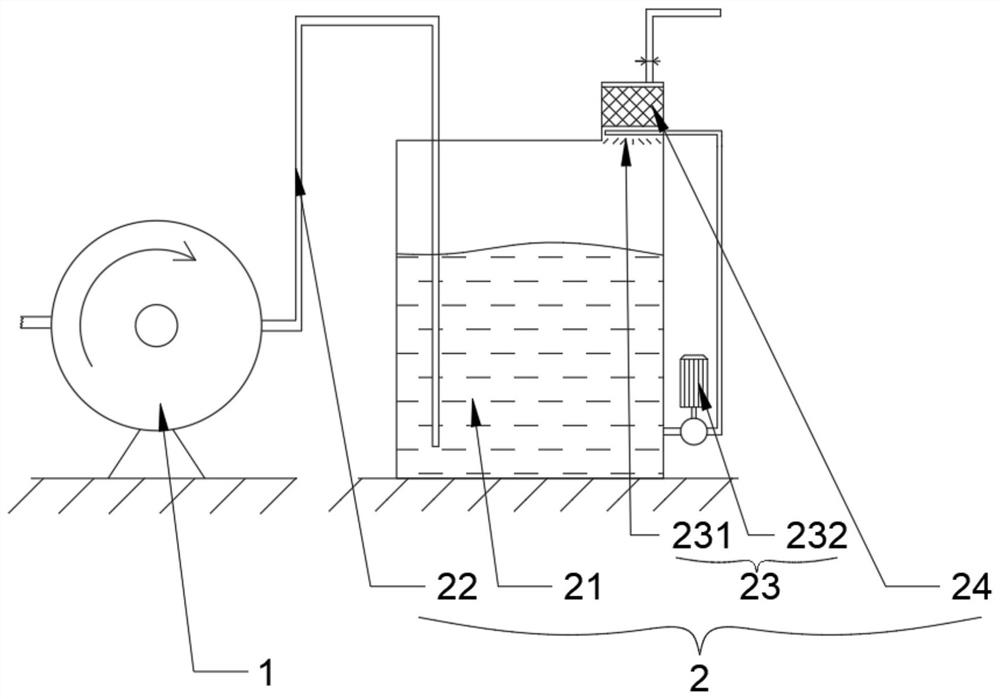

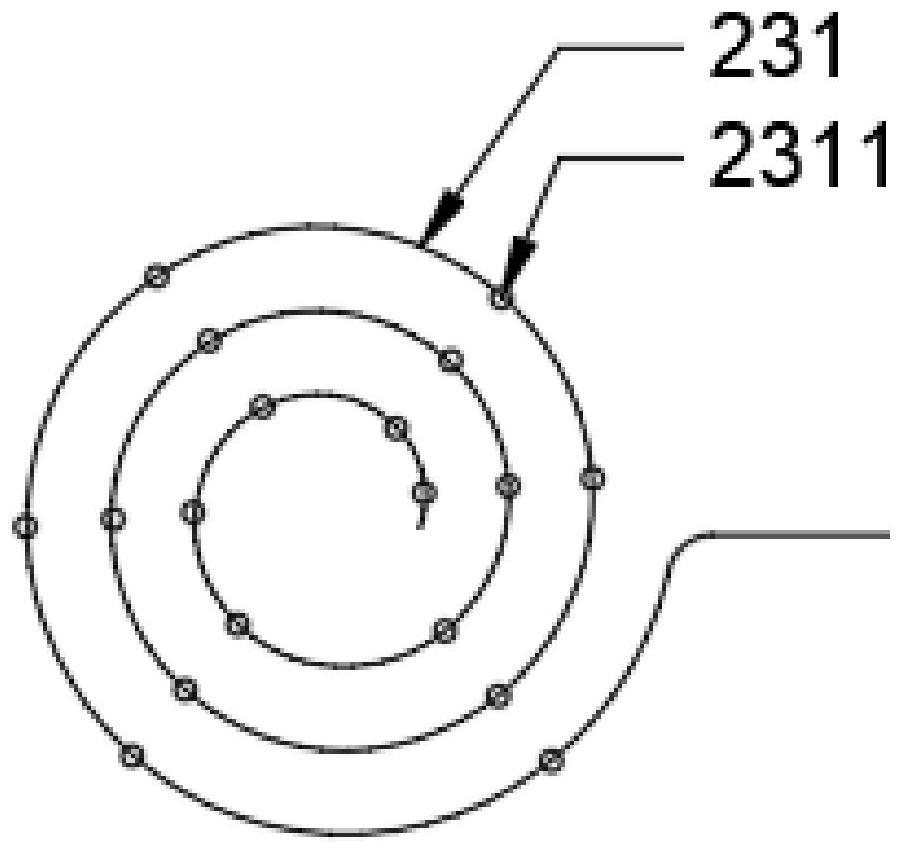

[0061] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

[0062] Such as Figure 1 to Figure 9 as shown,

[0063] A waste gas treatment device for a high-temperature retort pouch maturation chamber provided in this embodiment includes a booster fan 1, a pre-cleaning and drying part 2, an alkali cleaning part 3, an acid cleaning part 4, an acid removal part 5, a clean water part 6, and a terminal pH detector7. The input end of the booster fan 1 is connected with the waste gas outlet of the curing chamber through a pipeline. The booster fan 1 is used to increase the pressure of the waste gas, increase the flow rate of the waste gas, and can make the gas flow rate in the curing chamber faster, and improve the high-temperature cooking bag ripening. The aging effect is so that the exhaust gas can enter the exhaust gas treatment device smoothly. The input end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com