Method of reducing the self-heating propensity of biomass

A biomass and self-heating technology, applied in the direction of microorganism-based methods, biochemical equipment and methods, animal feed raw material preservation methods, etc., to achieve safe shipment and reduce the effect of self-heating tendency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

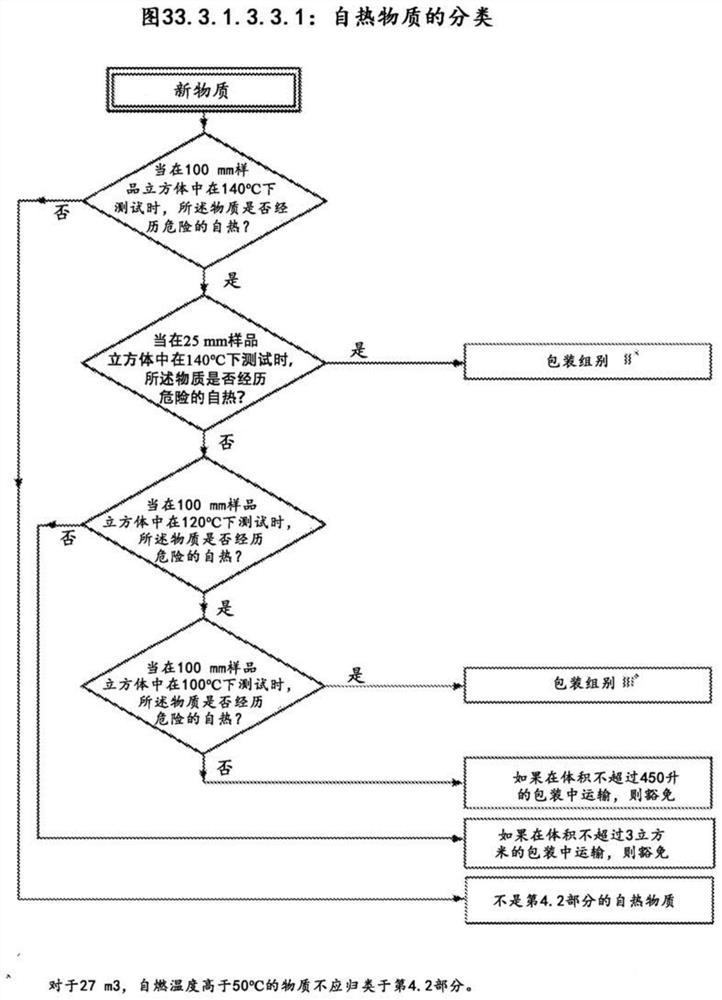

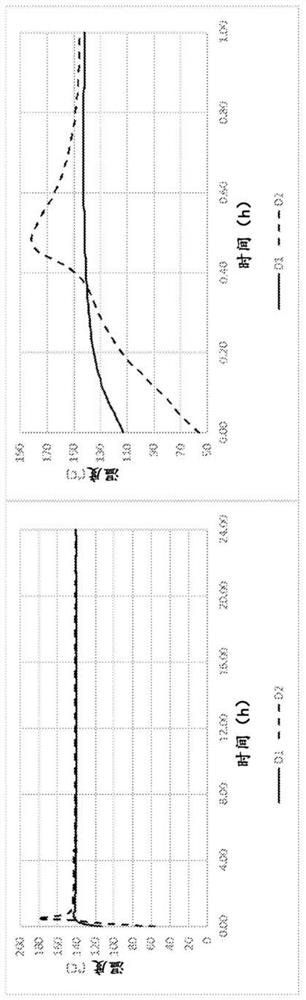

[0088] In this example, Schizochytrium sp. was grown in a fermentation vessel. Harvesting the fermentation broth early to obtain younger cells (D1) eliminated the autothermal property when compared to harvesting the broth at the end of the fermentation (D2). Both samples were dried by lyophilization. See Table 2. Two tests were performed on each of these two samples: 25mm cube at 140°C and 100mm cube at 100°C. The temperature characteristic curve of each test can be seen in Figure 2 and Figure 3. Self-heating is clearly seen in D2, where the temperature rises >60°C above the oven temperature set point, whereas no self-heating is observed in D1: when both are compared at 100°C using a 100mm cube , the sample temperature never rose above the oven temperature. Therefore, according to Figure 1, D2 would be classified in packing group III, and D1 would not be classified there.

[0089] Table 2

[0090]

[0091]

[0092] Next, test the harvest broth at different time poi...

Embodiment 2

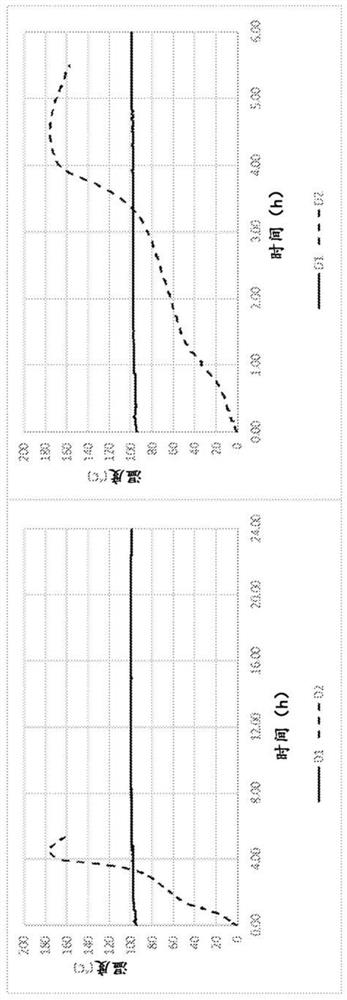

[0094] In this example, the same Schizochytrium sp. strain as in Example 1 was used. A comparison of non-pasteurized cells with pasteurized cells revealed unexpected and surprising results. Drying of the unpasteurized fermentation broth (D2) helped to improve the self-heating tendency compared to the dried broth after pasteurization (D3). See Table 3. Both samples were also dried by lyophilization. Two tests were performed on each sample: 25mm cube at 140°C and 100mm cube at 100°C. The temperature characteristic curve of each test can be seen in Figure 6 and Figure 7. For a 25mm cube at 140°C, D3 experienced dangerous self-heating, reaching a maximum temperature 60°C higher than D2. For a 100mm cube at 100°C, D3 reaches a maximum temperature 50°C higher than D2, while both rise above ambient oven temperature. Therefore, according to Figure 1, D3 would be classified as packing group II and D2 would be classified as packing group III.

[0095] table 3

[0096]

[0097]...

Embodiment 3

[0099] In this example, the same Schizochytrium sp. strain as in Example 1 was used. When the drying method was investigated, a surprising discovery was made. The self-heating properties were improved when the whole cell biomass (D4) was dried by rotary drum drying when compared to the whole cell biomass dried by lyophilization (D3). See Table 4. This is surprising when the difference between the residual moisture contents was not significant. Two tests were carried out on each of these samples: 25mm cube at 140°C and 100mm cube at 100°C. The temperature characteristic curve of each test can be seen in Figure 8 and Figure 9. For a 25mm cube at 140°C, each sample took about the same time to reach the maximum temperature, but the maximum temperature reached by D4 was 48°C lower than that of D3. For a 100mm cube at 100°C, the opposite is observed, the maximum temperature is about the same (about 230°C), but D4 takes 1.7 hours longer than D3 to reach this temperature. Based o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com