A wire tail fixer

A fixer and wire tail technology, which is applied in the field of wire tail fixators, can solve the problems of inconvenience in carrying, easy damage to wires, and reduced work efficiency, and achieves the effects of quick and convenient installation, beautiful appearance, and easy portability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

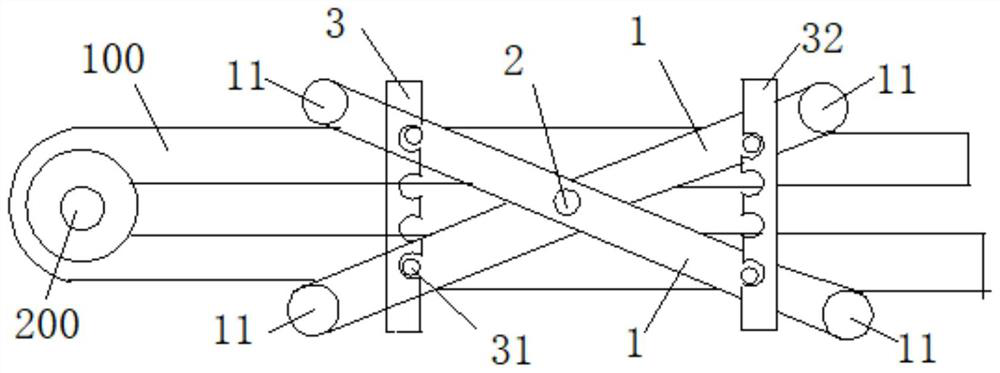

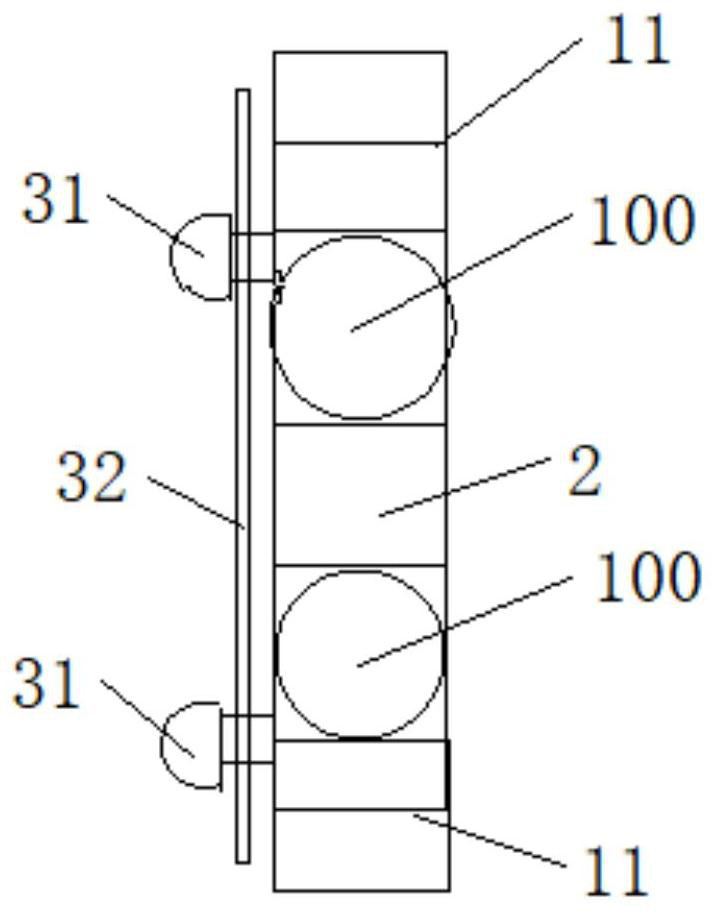

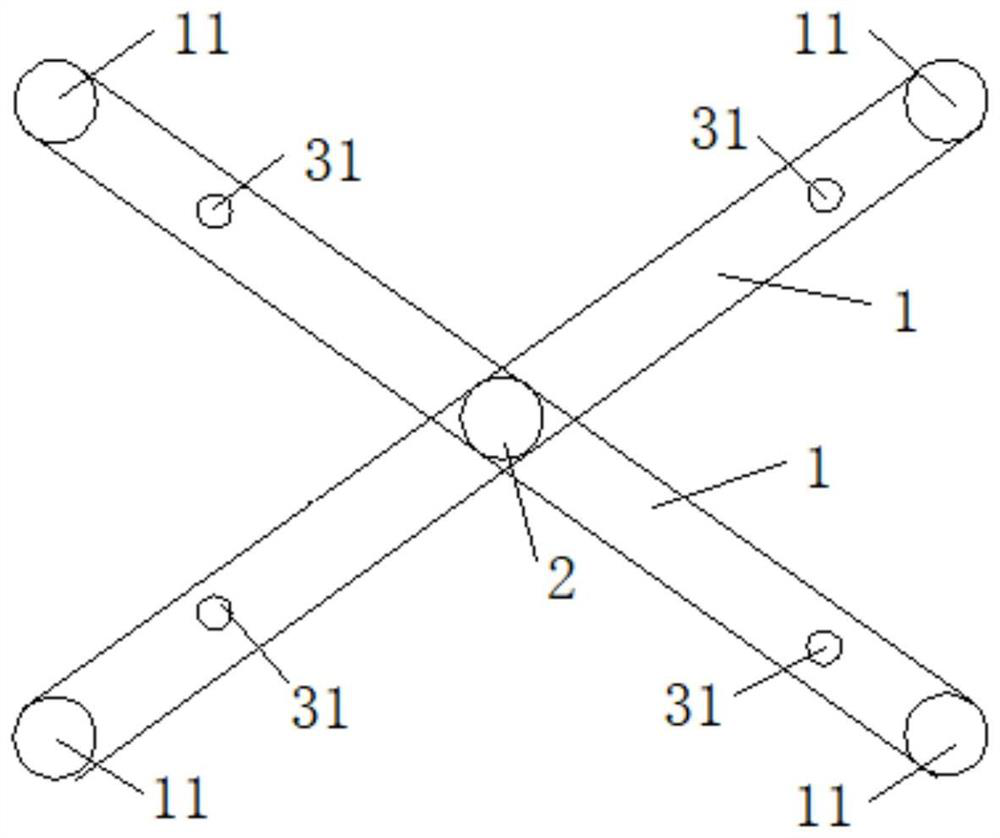

[0033] Such as Figure 1-Figure 4 As shown, the present invention provides a wire tail fixer, which includes two brackets 1, a connecting shaft 2 and a locking mechanism 3, the two brackets 1 are arranged crosswise, and the two ends of the bracket 1 are respectively provided with an anti-damage wire fixing shaft 11; The connecting shaft 2 is arranged at the intersection of the two brackets 1, and the two brackets 1 are connected through the rotation of the connecting shaft 2. One end of the connecting shaft 2 protrudes relative to the two brackets 1, and the two brackets 1 can clamp the wire 100 when they rotate. The locking mechanism 3 can lock the two brackets 1 when the wire 100 is interposed between the fixed shaft 11 and the connecting shaft 2 of the anti-injury line.

[0034] In this embodiment, the wire end fixer is made of high-strength steel and painted material, and adopts a sliding surface design. Two brackets 1 are symmetrically arranged in an X-shaped structure, a...

Embodiment 2

[0043] The thread tail retainer provided by the embodiment of the present invention has the same support 1 , the wound-proof thread fixing shaft 11 , the connecting shaft 2 , the bolt fixing column 31 and the multi-hole bolt 32 as those in the first embodiment. The difference between this embodiment and Embodiment 1 is that the anti-slip effect of the anti-injury line fixed shaft 11 is further enhanced, the friction between the wire 100 and the anti-injury line fixed shaft 11 is increased, and the wire 100 is prevented from moving along the anti-injury line fixed shaft 11 Axial slippage.

[0044] Optionally, an insulating rubber layer is provided on the surface of the anti-injury line fixing shaft 11, which not only increases the friction between the anti-injury line fixing shaft 11 and the wire 100, does not damage the wire 100, but also strengthens the connection between the wire 100 and the wire tail fixer. insulation effect. In addition, anti-slip protrusions can also be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com