Preparation method of nickel sulfide nanosheet anchored on inner surface of nitrogen-containing hollow carbon matrix, prepared product and application thereof

A hollow carbon, inner surface technology, applied in the field of nanomaterials, can solve the problems of limited theoretical capacity, poor stability, and inability to meet the needs of applications, and achieve the effect of reducing diffusion distance, excellent stability, and large electrolysis-electrode contact area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

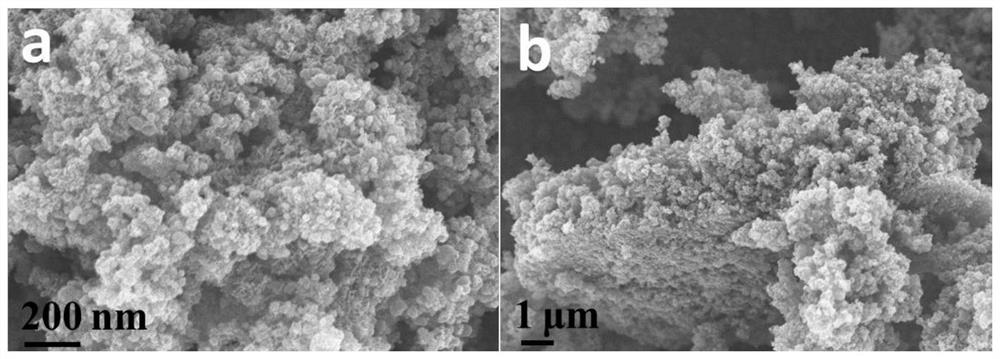

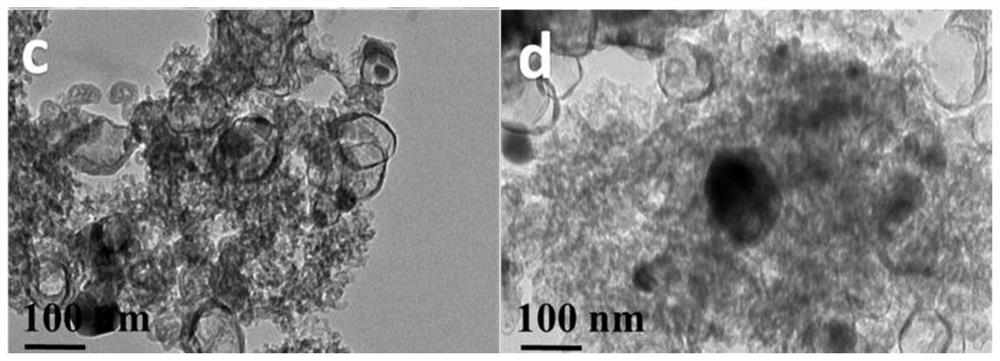

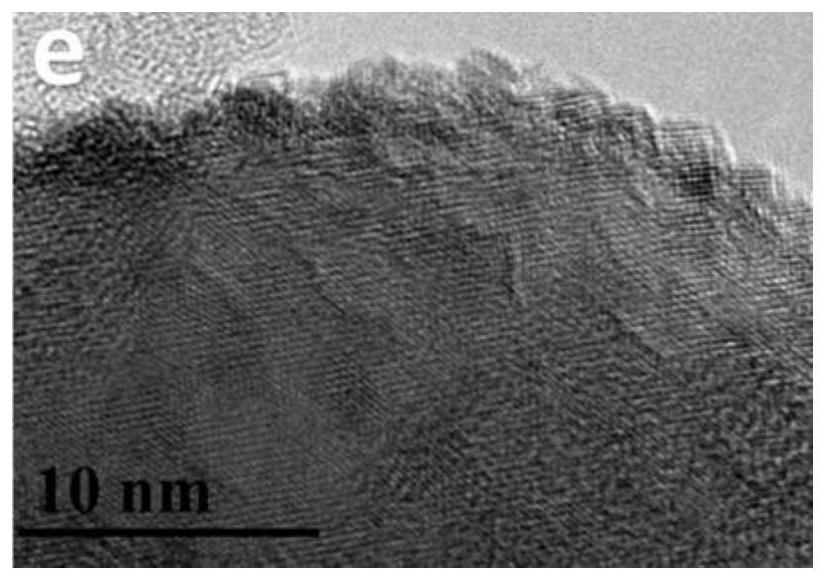

[0054] A method for preparing nickel sulfide nanosheets anchored on the inner surface of a nitrogen-containing hollow carbon matrix, specifically comprising the following steps:

[0055] (1) At room temperature, 237mg of nickel chloride was dissolved in 15mL of methanol to form solution A, and 300mg of polyvinylpyrrolidone and 328mg of 2-methylimidazole were dissolved in 15ml of methanol to form solution B.

[0056] (2) Mix the obtained solution A and solution B with stirring and slowly drop them together. After the mixture was stirred for 5 min, it was allowed to stand at room temperature for 24 h. The prepared samples were centrifuged, washed three times with methanol, and then dried in an oven at 60 °C for 6 h to obtain a yellow precursor.

[0057] (3) Carbonize the prepared precursor in a nitrogen atmosphere at 600 °C at a heating rate of 10 °C / min for 2 h to obtain a black sample, which is ultrasonically dispersed into 30 mL of deionized water, and then 10 mL of hydroch...

Embodiment 2

[0065] A method for preparing nickel sulfide nanosheets anchored on the inner surface of a nitrogen-containing hollow carbon matrix, specifically comprising the following steps:

[0066] (1) At room temperature, 240.5 mg of nickel chloride was dissolved in 15 mL of methanol to form solution A, and 300 mg of polyvinylpyrrolidone and 492 mg of 2-methylimidazole were dissolved in 15 mL of methanol to form solution B.

[0067] (2) Mix the obtained solution A and solution B with stirring and slowly drop them together. After the mixture was stirred for 5 min, it was allowed to stand at room temperature for 24 h. The prepared samples were centrifuged, washed three times with methanol, and then dried in an oven at 60 °C for 6 h to obtain a yellow precursor.

[0068] (3) Carbonize the prepared precursor in a nitrogen atmosphere at 600 °C at a heating rate of 10 °C / min for 2 h to obtain a black sample, which is ultrasonically dispersed into 30 mL of deionized water, and then 10 mL of ...

Embodiment 3

[0071] Adopt the nickel sulfide nanosheet in embodiment 1 to prepare sodium ion, potassium ion battery negative electrode material, specifically comprise the following steps:

[0072] Mix the nickel sulfide nanosheets anchored on the inner surface of the nitrogen-containing hollow carbon matrix, acetylene black and polyvinylidene fluoride at a mass ratio of 80:10:10 to form a slurry, and then coat the slurry on the copper foil , and dried at 80°C to obtain electrode sheets.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com