Compact high-voltage large-current electromagnetic repulsion coil

A technology of electromagnetic repulsion and high voltage, applied in the direction of coils, circuits, electrical components, etc., can solve the problems of coils and their insulation encapsulation mechanical impact, mechanical and insulation reliability threats, etc., to improve the effective current-carrying volume, solve the problem of mechanical The effect of insufficient strength and reduced volume overhead

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017]The invention will be further described in detail below with reference to the accompanying drawings:

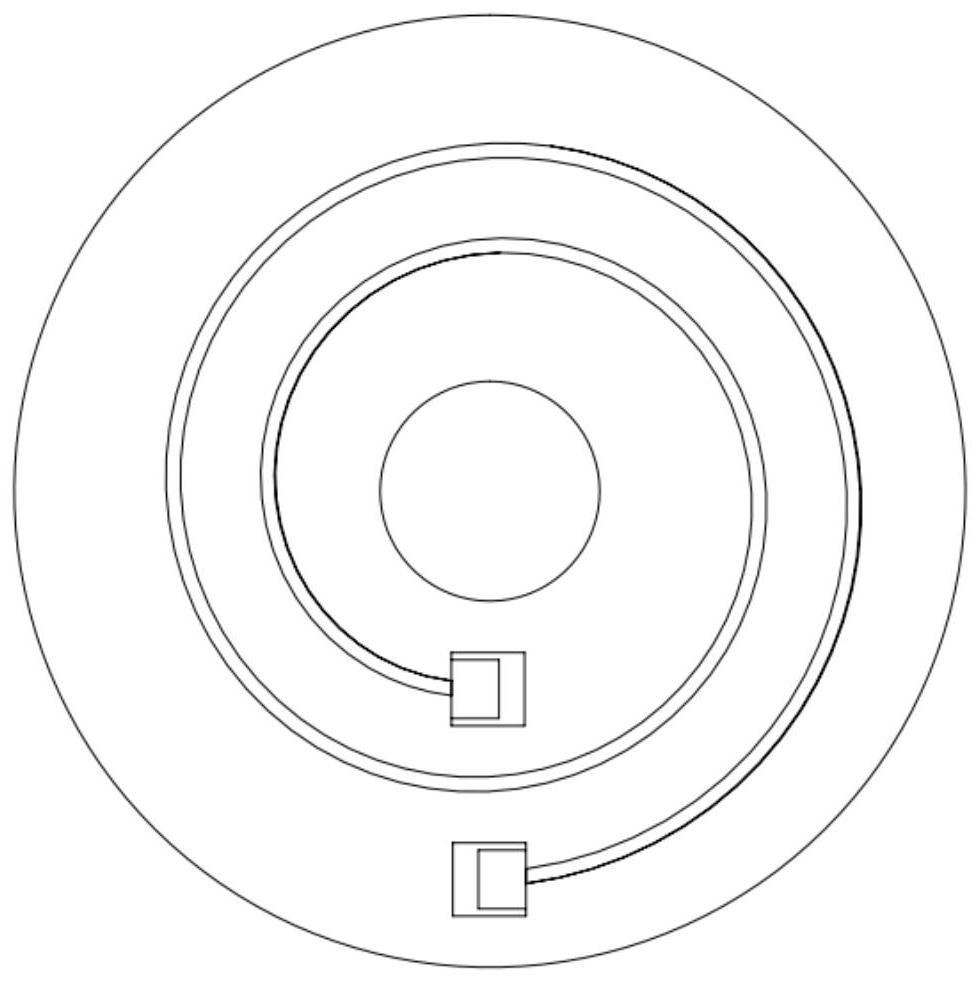

[0018]referencefigure 1 andfigure 2The compact high voltage large current electromagnetic repulsion coil according to the present invention includes a valve-specific metal disc, and the valve-specific metal disc is cut to form a cutting slit to form a coil winding 1, the center position of the valve-resistant metal disc. The guide hole 5 is opened, wherein the cutting slit is located around the guide hole 5, and the guiding hole 5 is formed between the inner edge conductive ring 6 between the cutting slits, and the cutting slit is formed between the outer circumference surface of the valvewide metal disc. 9. The ceramic oxide layer 2 and the transition metal layer 3 are sequentially provided on the surface of the surface of the valve-specific metal disc, and the transition metal layer 3 in the cutting slit is provided, and the transition metal layer 4 is provided on the transiti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com