Drying device for non-woven fabric production

A drying device, non-woven technology, applied in drying, dryer, progressive dryer and other directions, can solve the problems of long time and low drying efficiency, and achieve the effect of avoiding wrinkles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

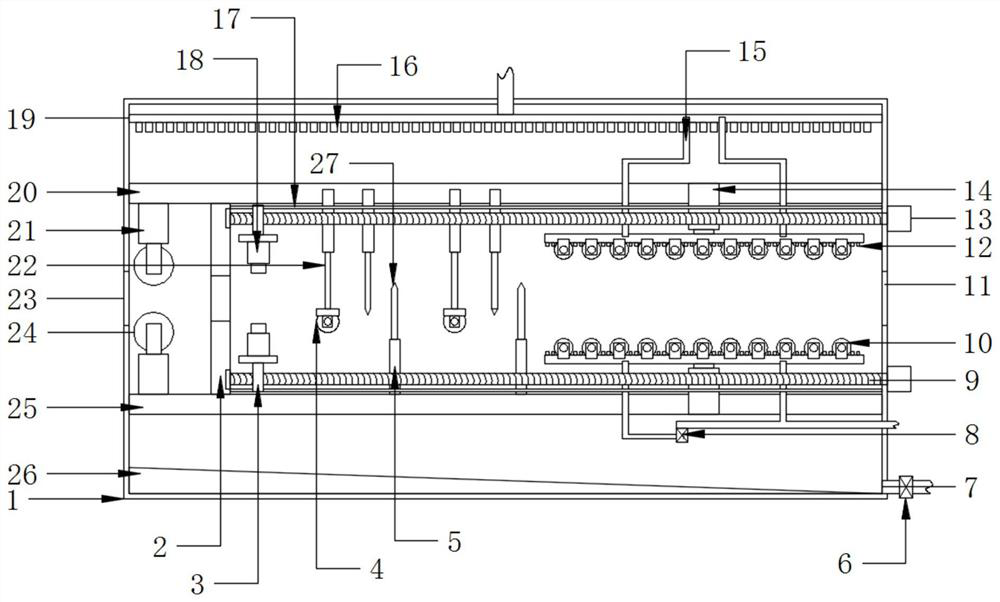

[0020] see Figure 1-4 , a drying device for non-woven fabric production, comprising a drying box 1 and a drying structure, the inside of the drying box 1 is provided with a drying structure, and the drying structure includes an inlet 23, a cloth outlet 11 , cloth clamping and guiding structure, inlet water squeezing structure, intermediate water squeezing structure, end drying structure and winding structure, the two sides of the drying box 1 are respectively provided with an inlet 23 and a cloth outlet 11, and the inlet The side of the mouth 23 is provided with an entrance water squeezing structure, and the side of the entrance water squeezing structure is provided with a cloth clamping and guiding structure. An end drying structure is arranged on the side, and a winding structure is arranged on the side of the cloth outlet 11 . First, the cloth enters from the inlet 23, and then the cloth is clamped and moved laterally by the cloth clamping and guiding structure, so that t...

Embodiment 2

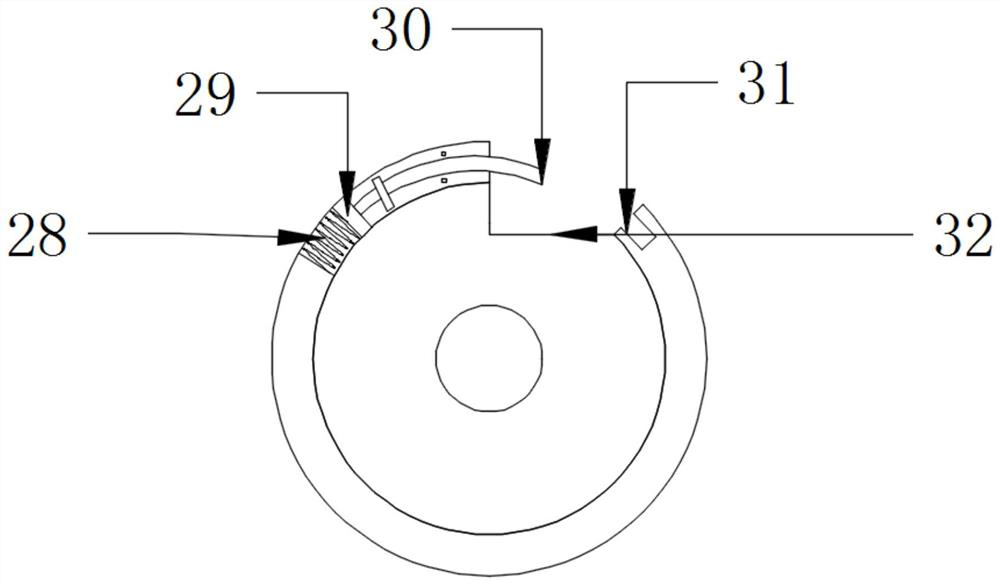

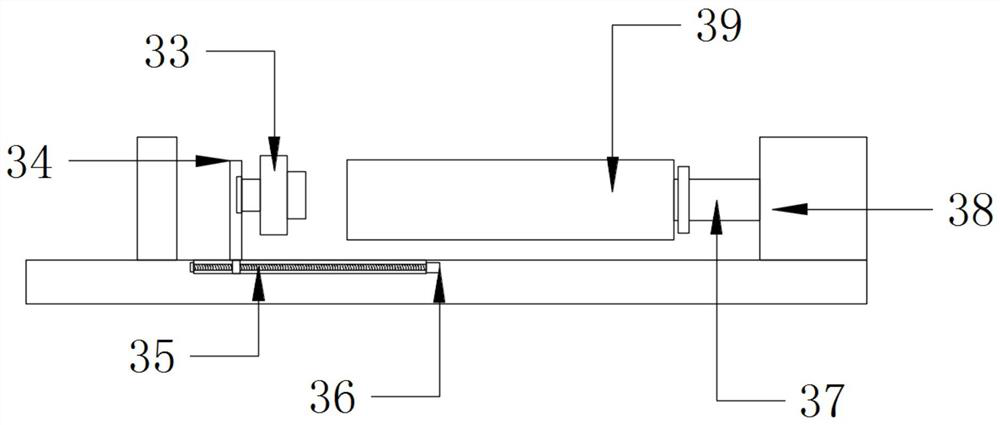

[0027] Compared with Embodiment 1, the improvement of this embodiment is that: the winding roller 39 is provided with an end clamping structure, and the end clamping structure includes a clamping spring 28, a clamping slider 29, an electromagnetic Clamping bolt 30, magnetic clamping groove 31 and clamping groove 32, described winding roller 39 side offers clamping groove 32, and described clamping groove 32 side offers magnetic clamping groove 31, and described clamping groove 32 The other end is provided with a sliding groove, and the inside of the sliding groove is slidably provided with a clamping slider 29, the end of the clamping slider 29 is fixed with a clamping spring 28, and the other end of the clamping slider 29 is provided with an electromagnetic card. The locking bolt 30 , the electromagnetic locking bolt 30 is matched with the locking groove 32 . First, the end of the non-woven fabric is placed inside the clamping groove 32, and then the magnetism of the electrom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com