Efficient alloy baking device and baking method thereof

A baking device and baking method technology, applied in chemical instruments and methods, drying, drying machines and other directions, can solve the problems of insufficient combustion of gas, low utilization rate of heat energy, carbon monoxide poisoning, etc., and achieve the elimination of residual gas. , Complete safety measures, the effect of avoiding poisoning accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

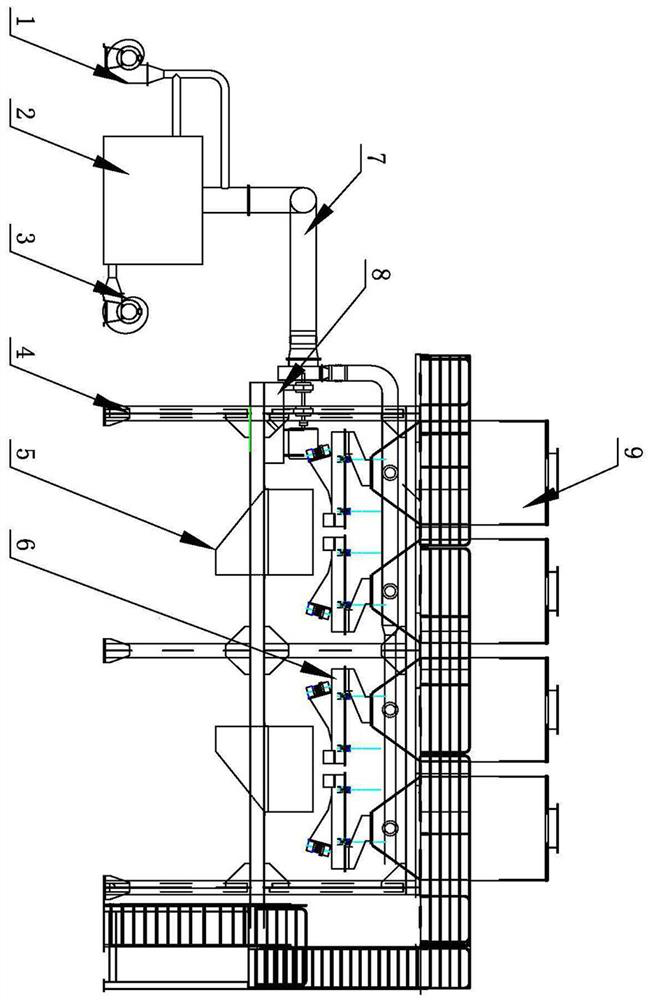

[0031] Below in conjunction with accompanying drawing, the present invention is further described:

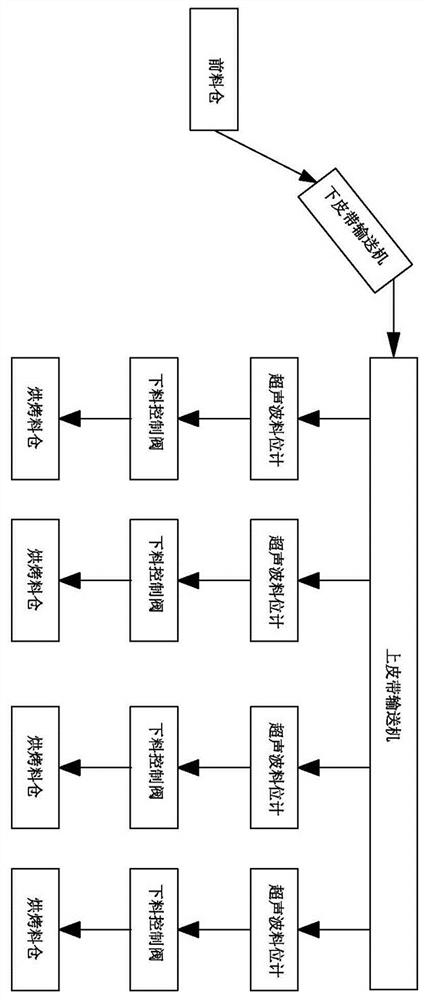

[0032] Such as Figure 1-2 A high-efficiency alloy baking device shown includes a hot blast stove 2, and the hot blast stove 2 is connected to the induced draft fan 8 mechanism through the hot blast pipeline 7, and is also provided between the induced draft fan 8 mechanism and the hot blast stove 2 Temperature adjustment mechanism, the induced draft fan 8 is connected to the baking bin 9, the baking bin 9 is arranged on the frame 4, the hot blast stove 2 is arranged on one side of the frame 4, and the baking A weighing and unloading mechanism is provided below the silo 9, and the baking silo 9 is also equipped with a feeding mechanism, and the hot blast stove 2 is controlled by an intelligent detection and control system.

[0033] Preferably, the intelligent detection and control system includes a nitrogen purge mechanism, a gas flow pressure detection mechanism, a flame detec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com