Immersed tube cement mixing pile, construction process and immersed tube device

A technology of cement-soil mixing piles and immersed pipes, which is applied in the direction of sheet pile walls, soil protection, and foundation structure engineering, and can solve the problems of uneven mixing of injected cement slurry and stirred soil, low vertical compressive bearing capacity, and pile The problem of uneven strength of the pile body can be solved, so as to achieve the effect of increasing the compactness, improving the bearing capacity, and ensuring the uniformity of the strength of the pile body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with specific embodiments.

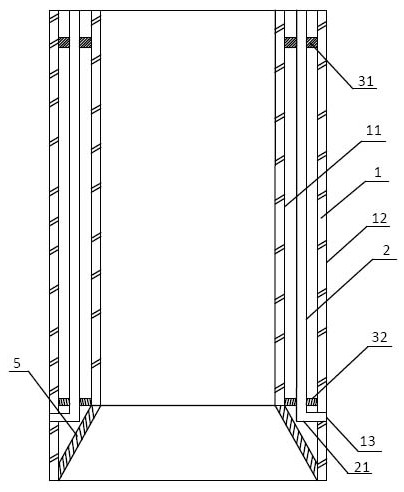

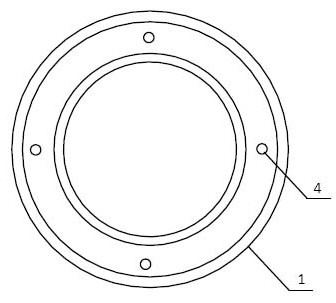

[0029] Such as figure 1 with figure 2 Shown, a kind of immersed tube device for cement-soil mixing pile, comprises immersed tube 1 and grouting tube 2, and described immersed tube 1 comprises inner tube 11 and outer tube 12, and the upper end of inner tube 11 and outer tube 12 The upper end is flush, the bottom end of the inner tube 11 is higher than the bottom end of the outer tube, the bottom end of the inner tube 11 is connected with the bottom end of the outer tube through the tapered sealing plate 5, and a ring is also arranged between the inner tube 11 and the outer tube 12. Supporting plate 3, mounting holes 4 are provided on the annular supporting plate 3; 4 mounting holes 4 are uniformly arranged on the annular supporting plate 3, the grouting pipes 2 are 4, and the 4 grouting pipes 2 are respectively installed on 4 Inside the installation hole 4. There are two...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com