Bamboo charcoal fiber production equipment with moisture regaining prevention function

A bamboo charcoal fiber and production equipment technology, which is applied in the field of bamboo charcoal fiber, can solve the problems of increasing the spacing of filamentous bamboo charcoal fibers, affecting the spinning of bamboo charcoal fibers, and affecting the accuracy of bamboo charcoal fiber spinning, so as to achieve the effect of preventing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Such as Figure 1-Figure 5 Shown:

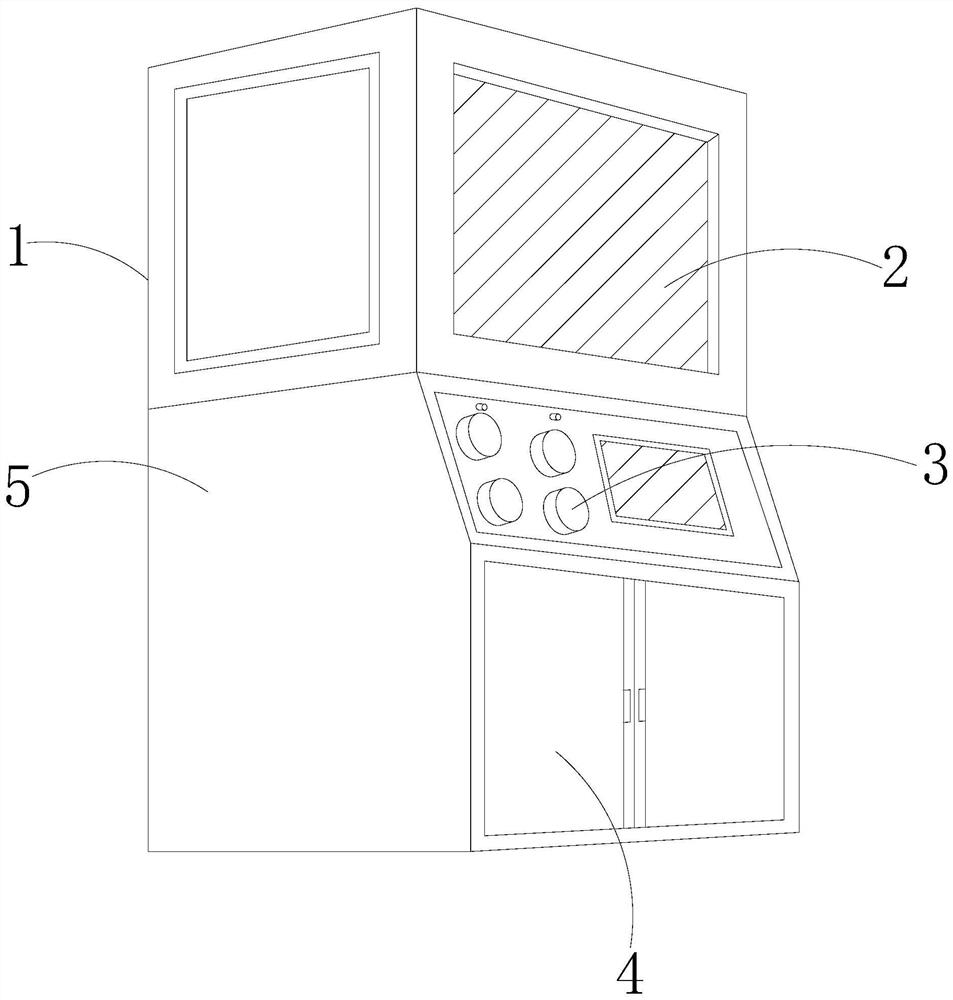

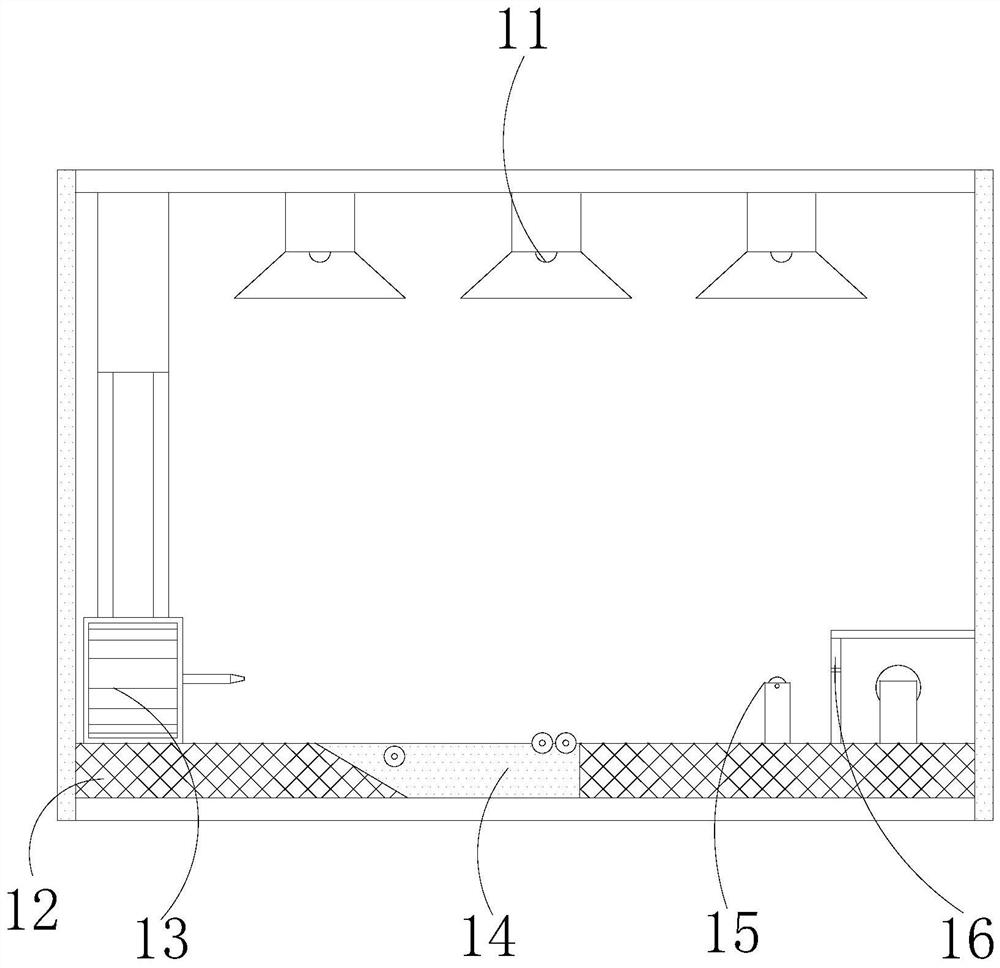

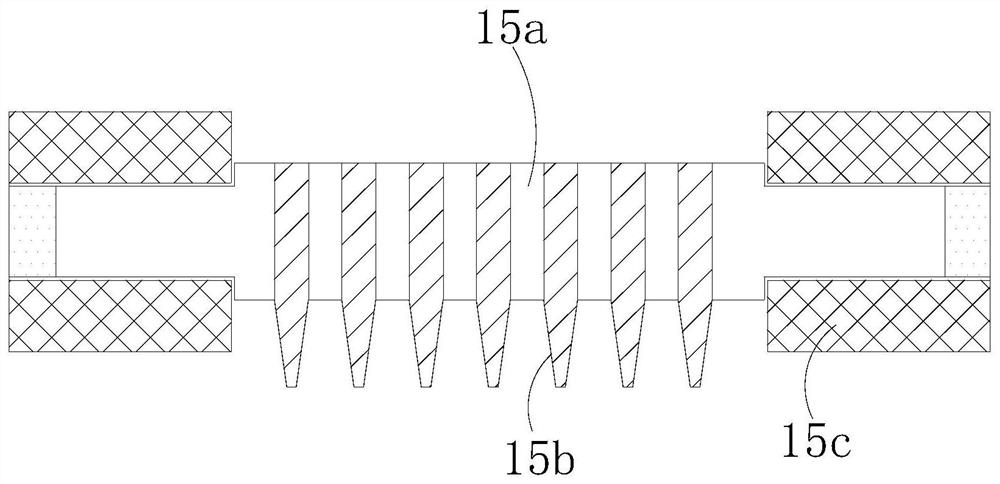

[0026] A kind of bamboo charcoal fiber production equipment with anti-moisture function of the present invention, its structure comprises molding device 1, observation window 2, controller 3, hinge door 4, device box 5, described observation window 2 is embedded and fixed on the surface of molding device 1 , the forming device 1 is installed on the upper end of the device box 5, the hinge door 4 is located on the surface of the device box 5, the controller 3 is attached to the side of the device box 5, and the controller 3 is located on the upper end of the hinge door 4, so The molding device 1 is composed of a heating lamp 11, a fixing plate 12, a former 13, a cooling tank 14, a guiding structure 15, and a bonding mechanism 16. Installed on the inner lower end of the fixed plate 12, the cooling groove 14 is located on the inner lower end surface of the fixed plate 12, the lower end of the guide structure 15 is welded on the inner lo...

Embodiment 2

[0033] Such as Figure 6-Figure 8 Shown:

[0034] Wherein, the bonding mechanism 16 is provided with a friction mechanism 16a, a friction hole 16b, a curved plate 16c, and a through plate 16d. On the central axis, the curved plate 16c is installed outside the friction mechanism 16a, and the lower end of the penetrating plate 16d is embedded in the inner lower end surface of the fixed plate 12. There are four curved plates 16c, with the friction mechanism 16a as the center circle The shape surrounds, so that the bamboo charcoal fiber in the friction hole 16b bears a force on the friction mechanism 16a, and the force is buffered by the curved plate 16c, so as to avoid excessive force on the bamboo charcoal fiber.

[0035] Wherein, the friction mechanism 16a is provided with a support ring a1, a dust removal mechanism a2, and a sphere a3. The sphere a3 is located inside the support ring a1, and the dust removal mechanism a2 is attached to the inside of the sphere a3. a2 is loca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com