Multi-section type carrier circulation switching machine

A switching machine and multi-stage technology, applied in the direction of conveyors, conveyor objects, lifting devices, etc., can solve problems such as inconvenient use, low cycle efficiency of vehicles, and complex design of conveying systems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to facilitate the understanding of those skilled in the art, the present invention will be further described below in conjunction with the embodiments and accompanying drawings, and the contents mentioned in the implementation modes are not intended to limit the present invention.

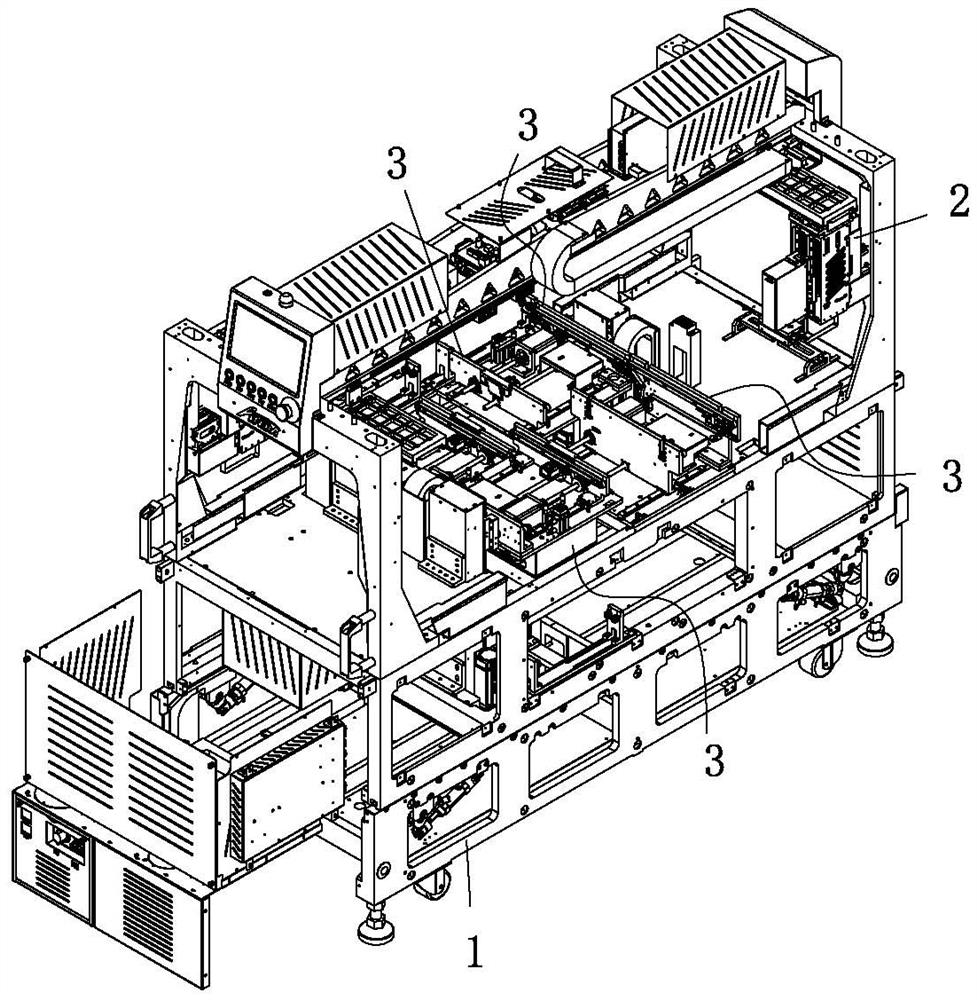

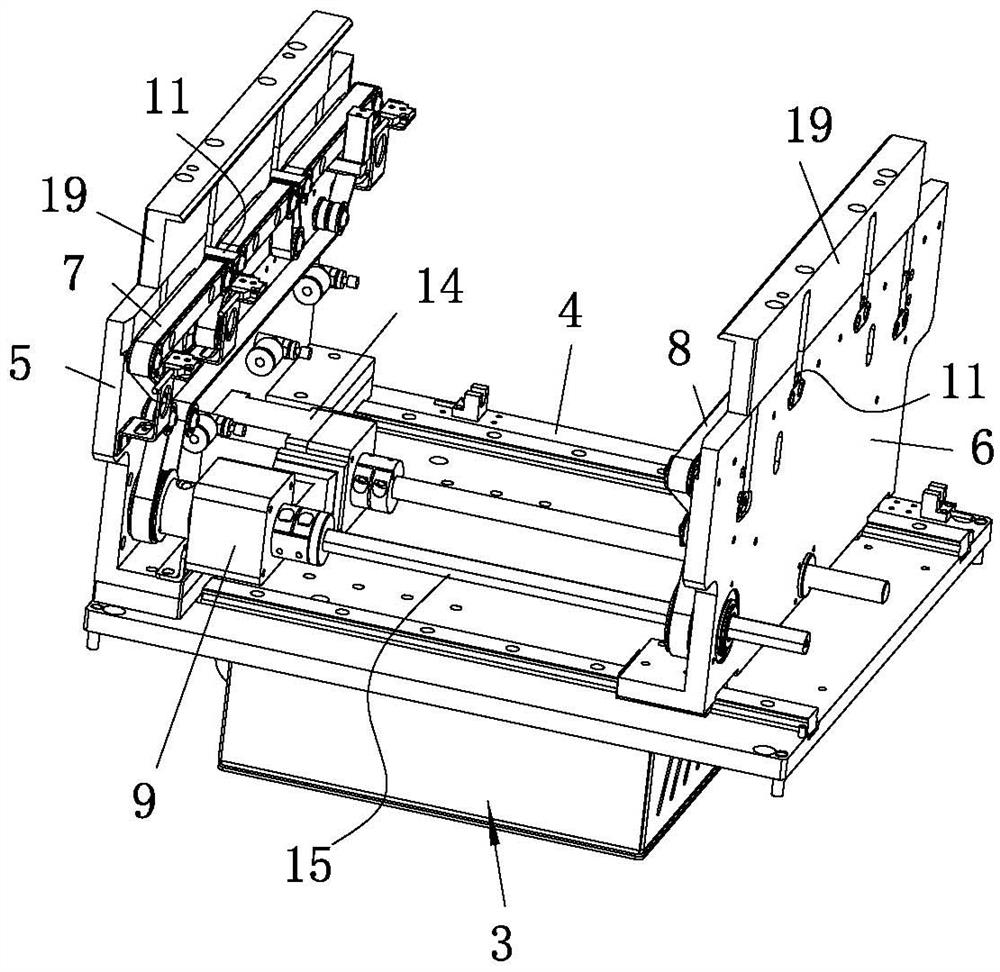

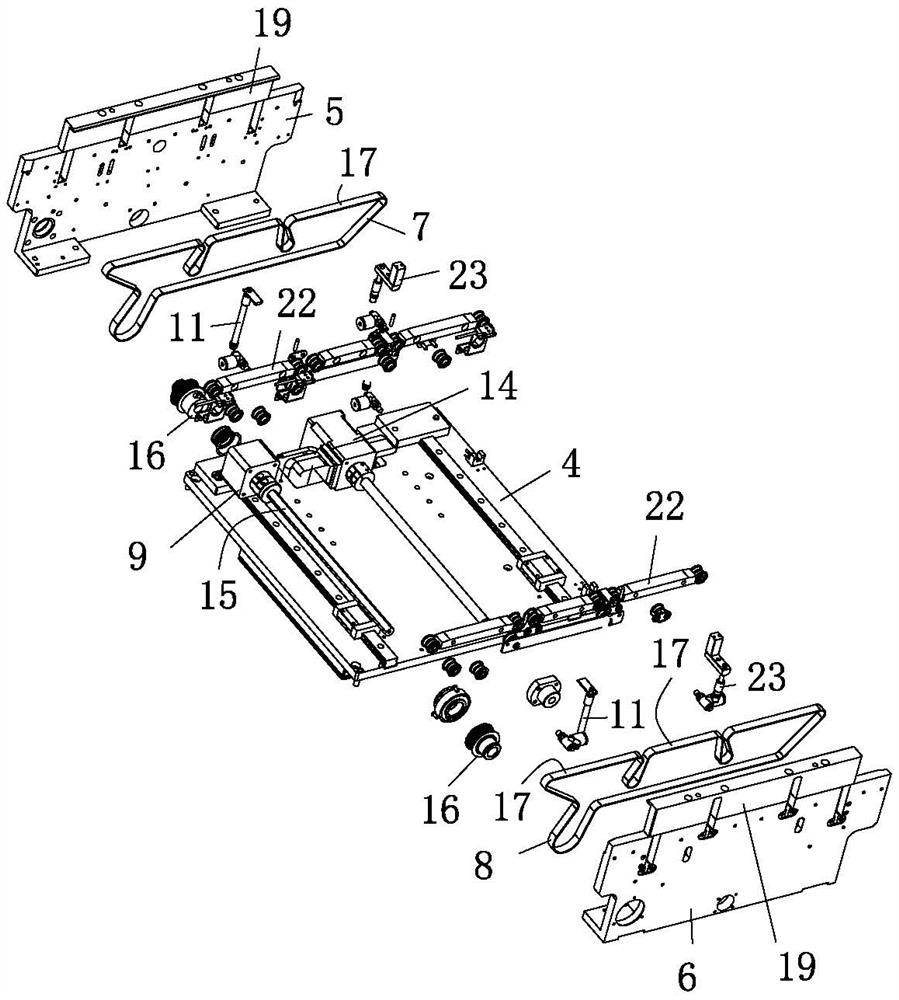

[0032] see Figure 1 to Figure 6 As shown, a multi-stage carrier cycle switching machine of the present invention includes a frame 1, a transfer mechanism 2 installed on the frame 1, and two conveying mechanisms 3, and the two conveying mechanisms 3 are respectively used to transfer the carrier Inputting and outputting the carrier, the transfer mechanism 2 is used to transfer the carrier between two conveying mechanisms 3 . In this embodiment, the frame 1 is welded by metal rods, and the transfer mechanism 2 and the delivery mechanism 3 are equipped with independent controllers, so that the transfer mechanism 2 and the delivery mechanism 3 become independent functional modules. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com