An intermittent multi-specification plastic injection molding machine

An injection molding machine and multi-specification technology, which is applied in the field of intermittent multi-specification plastic injection molding machines, can solve the problems of pouring port blockage, reduced practicality, and increased production costs, and achieve the effects of improving the mixing effect, reducing the amount of accumulation, and facilitating cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

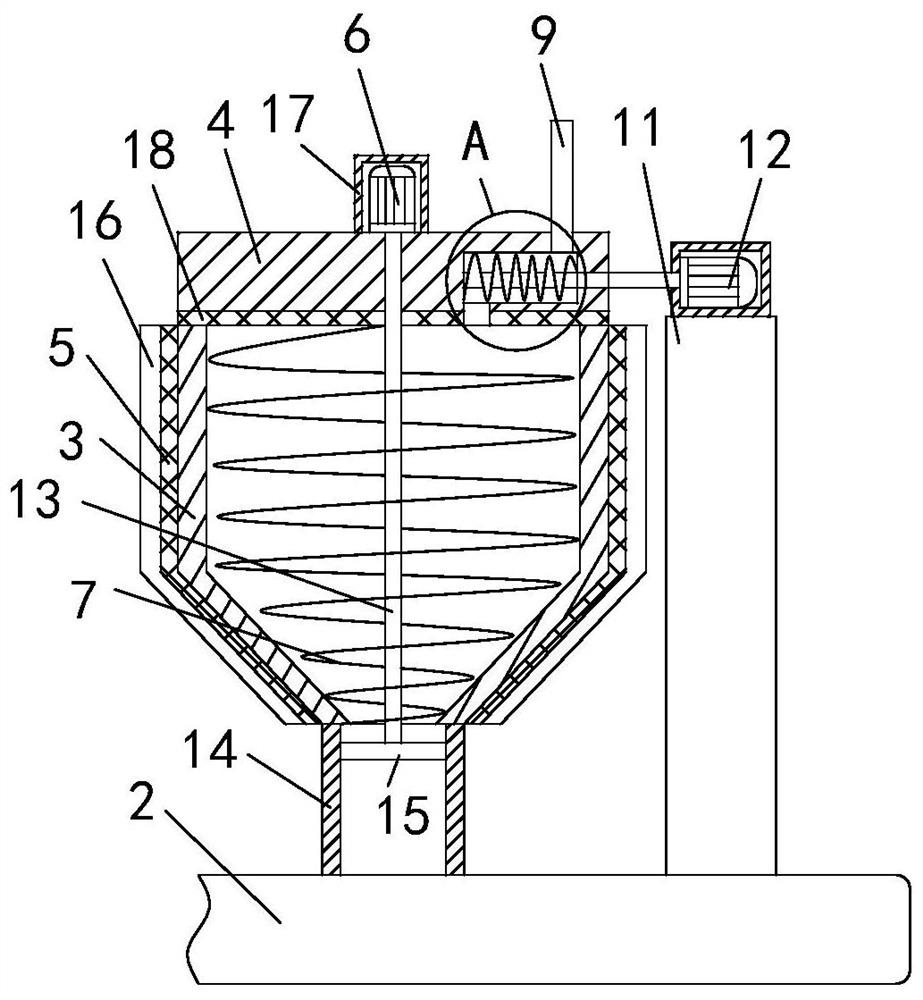

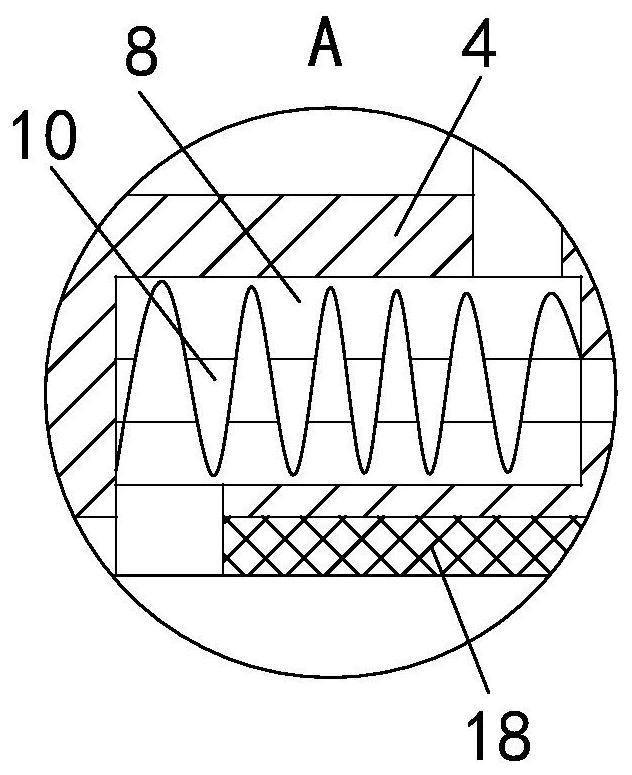

[0028] As a specific embodiment of the present invention, the wave unit 19 includes a hollow rubber layer 191, the hollow rubber layer 191 is symmetrically arranged on both sides of the helical blade 7, the hollow rubber layer 191 is fixedly connected to the helical blade 7, and the hollow rubber layer 191 has the same shape as the screw blade 7; a block 192 is provided between the hollow rubber layer 191 and the screw blade 7, the block 192 is fixedly connected to the screw blade 7, and oil is filled between the hollow rubber layer 191 and the screw blade 7 ;

[0029]When the wave unit 19 is working, it rotates with the rotation of the spiral blade 7. The wave unit 19 and the spiral blade 7 stir the injection molding raw materials. While stirring, the oil liquid flows between the spiral blade 7 and the The hollow rubber layer 191 flows, and in the process of flowing, the oil collides with the block 192, so that the oil fluctuates, and then the ability of the oil fluctuation i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com