A shock-resistant turning tool

An anti-vibration car and tool technology, applied in the field of cutting, can solve the problems of inability to suppress the vibration of the workpiece itself, and the effect is minimal, and achieve the effect of solving the surface quality substandard, excellent surface quality and cutting accuracy, and obvious anti-vibration effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

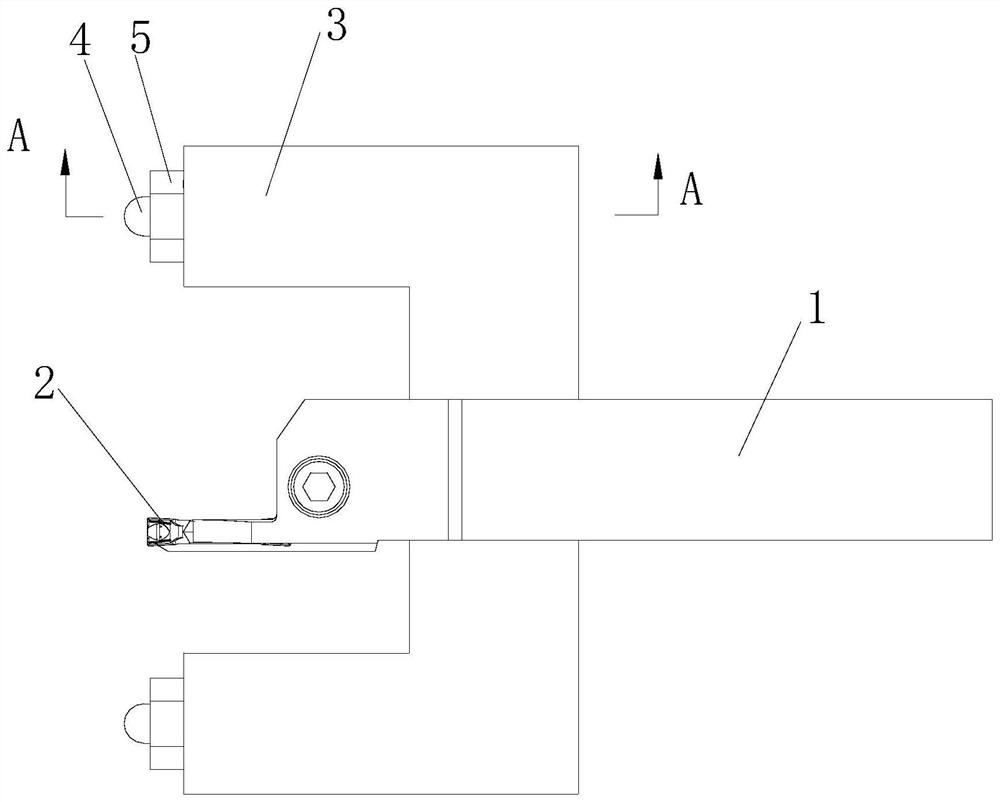

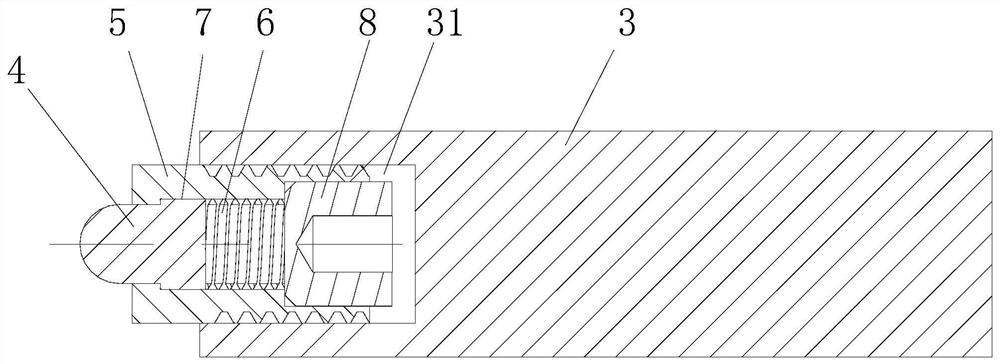

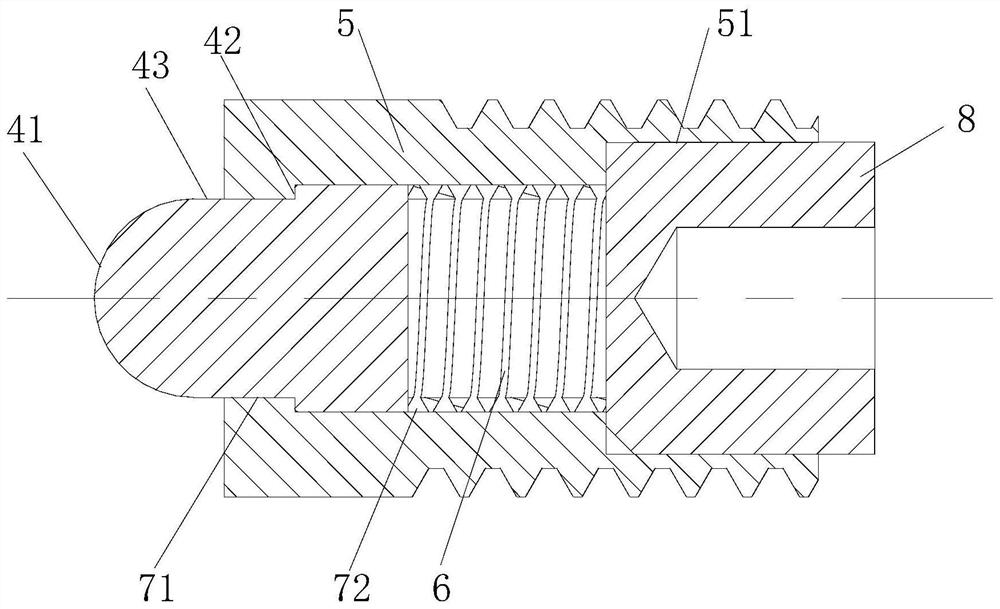

[0029] like Figure 1 to Figure 5 As shown, the anti-vibration turning tool of this embodiment includes a cutter body 1, a blade 2 and an anti-vibration assembly, the blade 2 is installed at the front end of the cutter body 1, and the anti-vibration assembly includes an anti-vibration arm 3, an anti-vibration compression member 4, a compression member base 5 and an elastic member 6. The anti-vibration arm 3 is installed on the cutter body 1, the pressure piece seat 5 is set at the front end of the anti-vibration arm 3, the pressure piece base 5 is provided with an installation groove 7, the anti-vibration pressure piece 4 and the elastic piece 6 are arranged in the installation groove 7, and The elastic member 6 is abutted between the anti-vibration compression member 4 and the groove bottom of the installation groove 7 , the front end of the anti-vibration compression member 4 is arranged outside the installation groove 7 , and an axial limit structure is arranged between the ...

Embodiment 2

[0039] like Figure 7 As shown, the anti-vibration turning tool of this embodiment differs from Embodiment 1 only in that:

[0040] In this embodiment, the insert 2 selects an external turning insert, and the principle of external turning is the same as that of face turning.

[0041] The remaining points that are not described are consistent with Embodiment 1, and are not repeated here.

Embodiment 3

[0043] The difference between the anti-vibration turning tool of this embodiment and Embodiment 1 is:

[0044] In this embodiment, the anti-vibration arm 3 is arranged on the cutter body 1 in an axially movable manner. By adjusting the axial displacement of the anti-vibration arm 3 on the cutter body 1 , the degree of contact between the spherical surface 41 of the anti-vibration compression member 4 and the workpiece 9 can be adjusted. In order to meet the anti-vibration requirements during cutting, the anti-vibration arm 3 can be adjusted so that the spherical surface 41 does not come into contact with the workpiece 9 when the anti-vibration is not required.

[0045] The remaining points that are not described are consistent with Embodiment 1, and are not repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com