Method for pre-lithiation of silicon-based negative electrode material

A silicon-based negative electrode material and pre-lithiation technology, applied in battery electrodes, electrochemical generators, structural parts, etc., can solve the problems of low initial charge and discharge efficiency and affect the popularization and application of silicon-based negative electrode materials, etc., to improve the initial efficiency , the reaction is uniform and sufficient, and the preparation environment is not demanding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

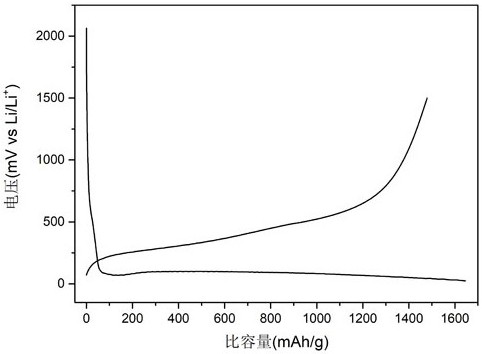

Image

Examples

Embodiment 1

[0018] A method for pre-lithiation of silicon-based negative electrode materials, dissolving aromatic hydrocarbon organic substances in organic ethers, preparing a solution containing aromatic hydrocarbons, putting lithium flakes into the solution, and using aromatic hydrocarbons to react with lithium flakes Obtain the precursor solution of aromatic hydrocarbon lithium salt, then, add the silicon-based negative electrode material into the precursor solution, obtain the suspension, carry out the pre-lithiation reaction, after standing for a period of time, put the suspension under the protection of an inert atmosphere Calcining after drying to obtain a pre-lithiated silicon-based negative electrode material, as follows:

[0019] Step 1: disposing biphenyl and ethylene glycol dimethyl ether into a solution A with a biphenyl concentration of 1M;

[0020] Step 2: Put the lithium flakes into the solution A prepared in step 1 for full reaction, the molar ratio of lithium flakes to b...

Embodiment 2

[0025] A method for pre-lithiation of silicon-based negative electrode materials, similar to the steps in Example 1, as follows:

[0026] Step 1: Prepare biphenyl and tetrahydrofuran into a solution A with a biphenyl concentration of 1M;

[0027] Step 2: Put lithium flakes into solution A for full reaction, the molar ratio of lithium flakes to biphenyl is 2:1, thereby obtaining solution B;

[0028] Step 3: Soak the silicon-based negative electrode material in solution B and stir to form a suspension, and let it stand for 24 hours;

[0029] Step 4: The suspension is filtered, dried, and calcined at 700° C. to obtain the target product, the pre-lithiated silicon-based negative electrode material.

Embodiment 3

[0031] A method for pre-lithiation of silicon-based negative electrode materials, similar to the steps in Example 1, as follows:

[0032] Step 1: Prepare biphenyl and tetrahydrofuran into a solution A with a biphenyl concentration of 1M;

[0033] Step 2: Put lithium flakes into solution A for full reaction, the molar ratio of lithium flakes to biphenyl is 1.2:1, thereby obtaining solution B;

[0034] Step 3: Soak the silicon-based negative electrode material in solution B and stir to form a suspension, and let it stand for 12 hours;

[0035] Step 4: The suspension is filtered, dried and calcined at 800° C. to obtain the target product, the pre-lithiated silicon-based negative electrode material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com