A waste plastic recycling equipment for cable production

A technology of waste plastics and recycling equipment, applied in the field of cable production, can solve the problems of not having height and adjusting the height of the cutter, inconvenient wire transportation, inconvenient wire harness separation, etc., to achieve the effect of convenient height and avoid following rotation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

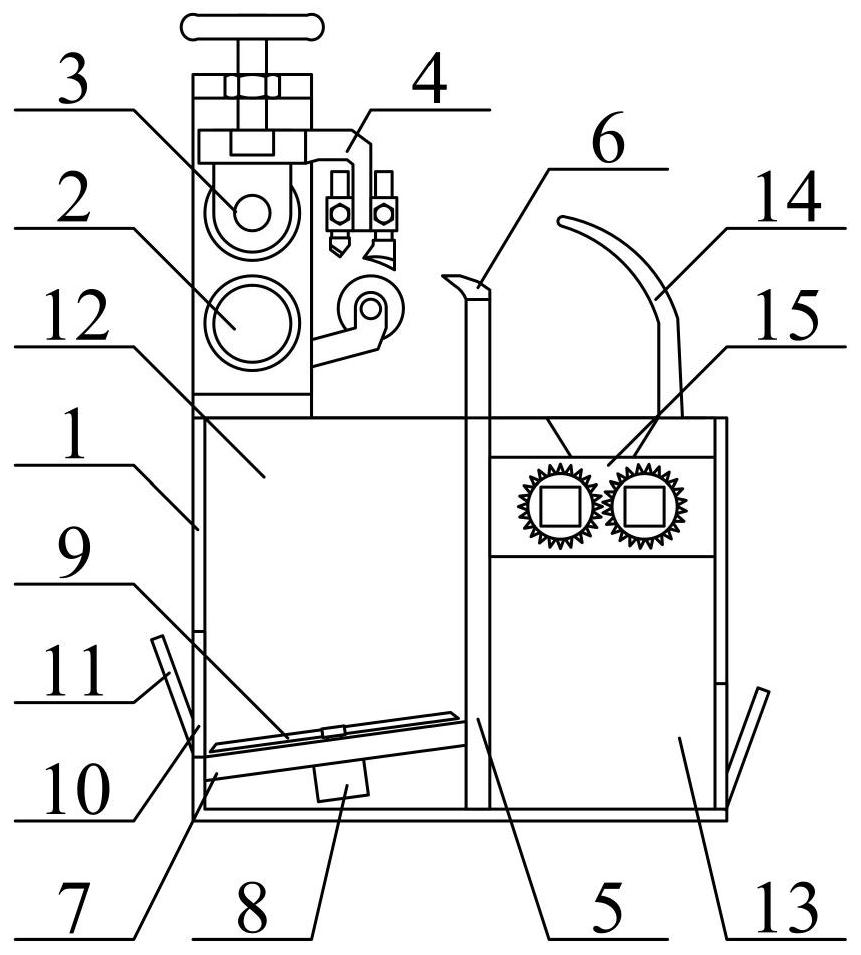

[0041] as attached figure 1 and attached Figure 4 shown

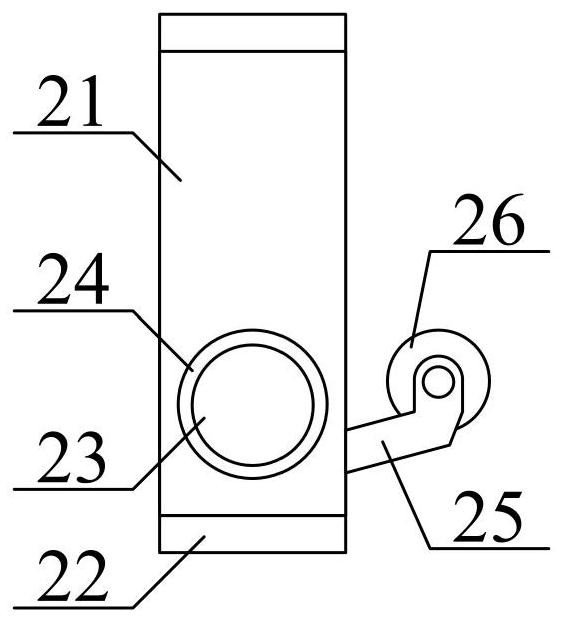

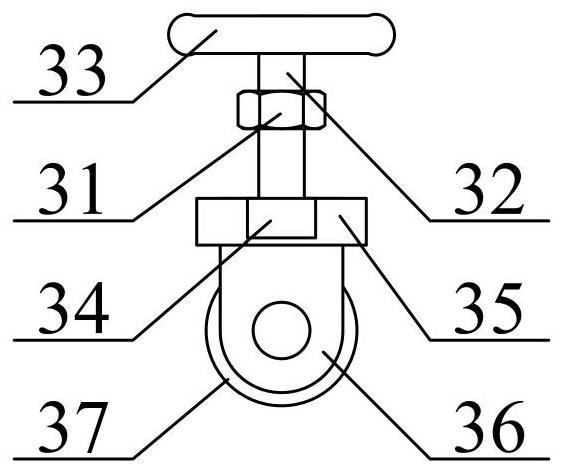

[0042]The present invention provides a waste plastic recycling equipment for cable production, comprising a fixed outer frame 1, a cable conveying positioning frame structure 2, an adjustable cable clamping fixing frame structure 3, an adjustable cable peeling frame structure 4, a longitudinal fixing plate 5. Separation scraper 6, material guide plate 7, crushing motor 8, crushing knife 9, lead-out frame 10, protective door 11, material storage cavity 12, core storage cavity 13, guide cover 14 and core rolling frame structure 15. The cable conveying positioning frame structure 2 is installed on the upper left side of the fixed outer frame 1; The cable peeling frame structure 4 is installed on the upper right side of the cable conveying positioning frame structure 2; the longitudinal fixing plate 5 is bolted to the inner middle position of the fixed outer frame 1; the separating scraper 6 is welded on the longitudinal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com