Concrete diaphragm wall construction method

A concrete anti-seepage wall and construction method technology, applied in sheet pile walls, foundation structure engineering, construction, etc., can solve the problems of poor connection firmness of anti-seepage walls

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

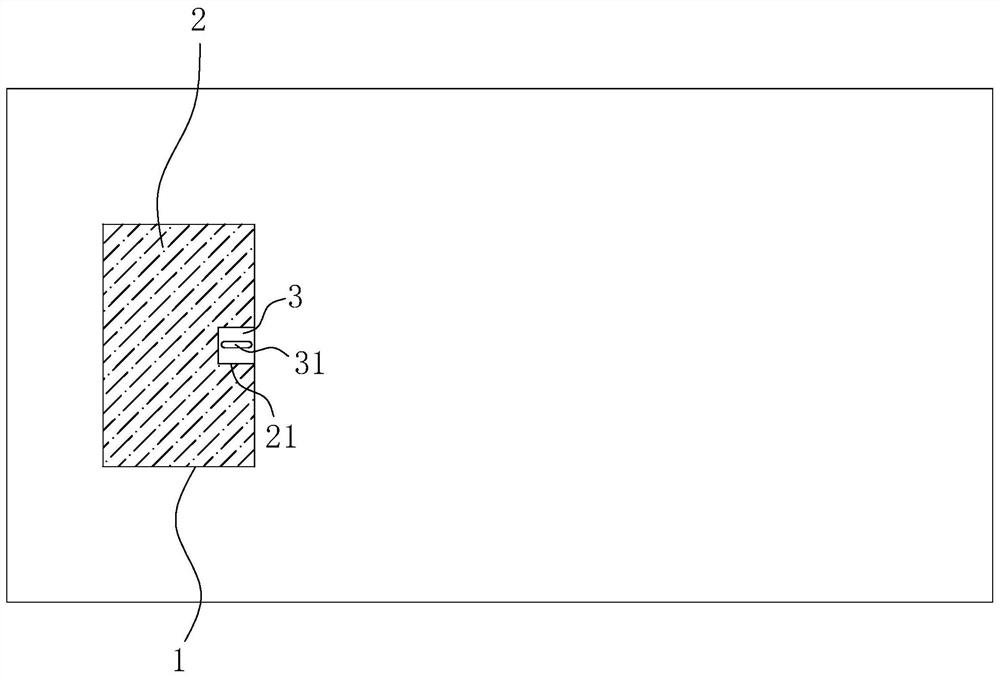

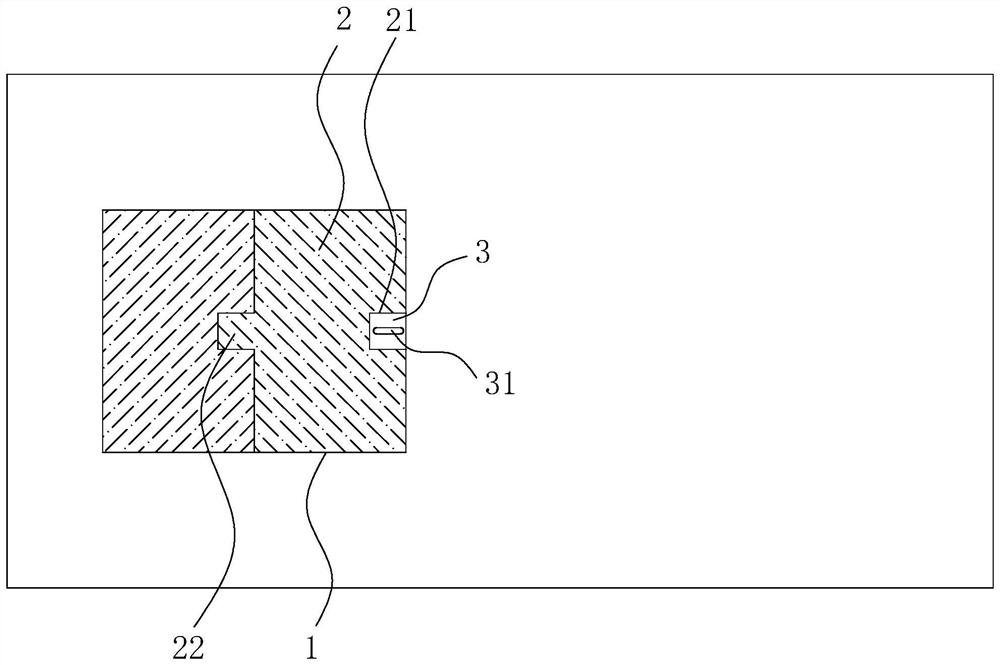

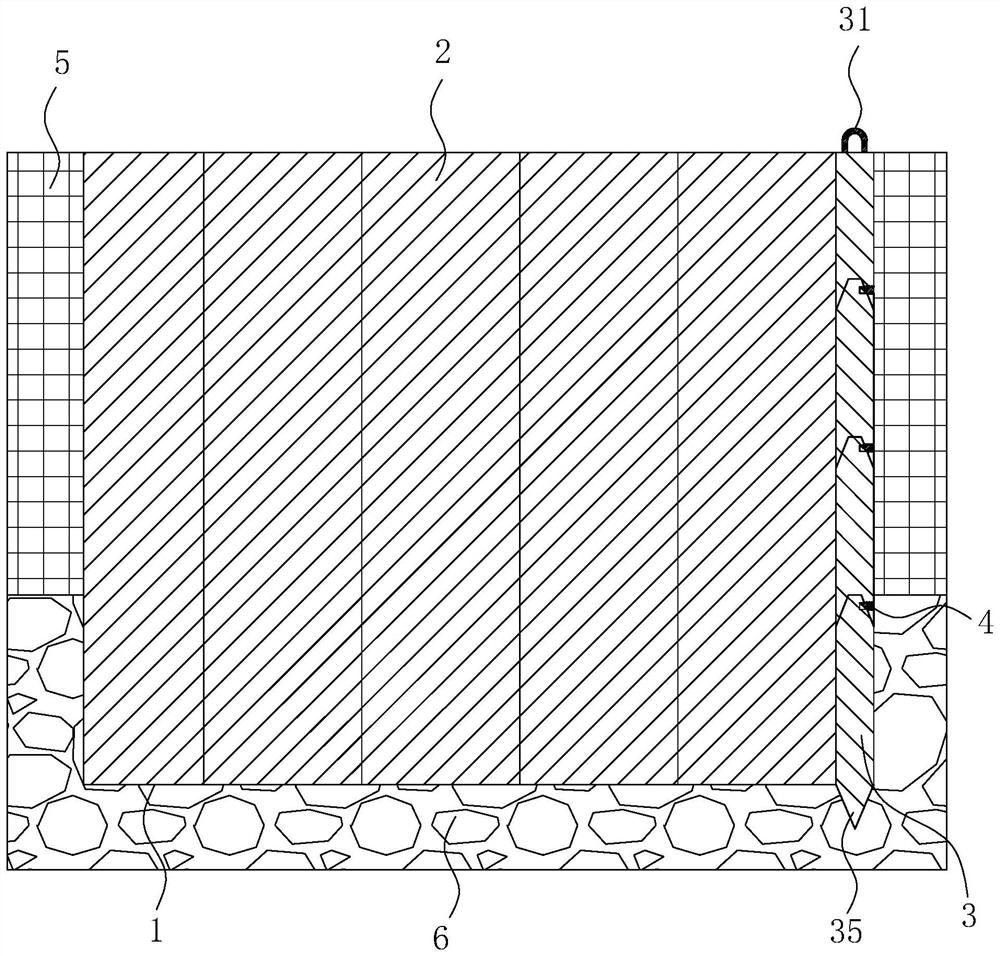

[0043] The following is attached Figure 1-5 The application is described in further detail.

[0044] The embodiment of the present application discloses the construction method of the concrete anti-seepage wall, and the construction method of the concrete anti-seepage wall comprises the following steps:

[0045] S1, refer to image 3 , Use site leveling machinery to level the area where holes will be excavated.

[0046] S2, refer to image 3 , After the site leveling is completed, measure and draw lines on the construction ground according to the final design drawings of the concrete cut-off wall. The entire concrete cut-off wall will be constructed in strict accordance with the markings on the construction ground. The equipment enters the construction area and a mud purification system is built nearby.

[0047] S3, refer to image 3 , after all the equipment is ready, use large-scale excavating machinery to excavate the slotted hole 1 according to the marking line on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com