Composite pavement road with asphalt layer coated on sisal hemp fiber cement-based composite material

A composite pavement and sisal fiber technology, applied in roads, roads, pavement details, etc., can solve problems such as poor wear resistance, achieve good performance, improve temperature and humidity conditions, and improve crack resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

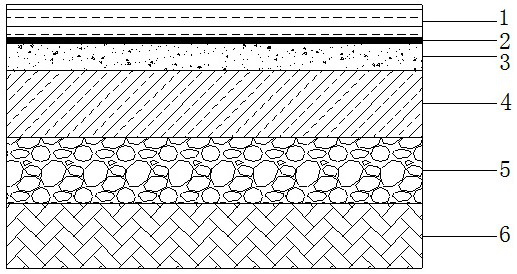

[0024] A composite pavement road covered with asphalt layer on sisal fiber cement-based composite material, which is applied to trunk roads with heavy traffic volume. This project is a reconstruction and expansion project, such as figure 1 Shown is the cross-sectional design drawing of the pavement structure of the reconstruction plan.

[0025] The sisal fiber cement-based composite material is covered with an asphalt layer composite pavement structure. From bottom to top: a cement graded crushed stone subbase 5 is laid on the roadbed 6, and a cement graded crushed stone subbase 5 is laid on the cement graded crushed stone subbase 5. Cement stabilized crushed stone base 4, on which sisal fiber ECC layer 3 is laid, on said sisal fiber ECC layer 3, interface performance enhancement layer 2 is laid, on which interface performance enhancement layer 2 is laid. Epoxy asphalt concrete layer 1 is laid.

[0026] The material of the load-bearing layer is sisal fiber cement-based compos...

Embodiment 2

[0043] Modify the raw material formula of sisal fiber cement-based composite material to: water 290kg / m 3 , 42.5 grade ordinary Portland cement 310kg / m 3 , fine sand 680kg / m 3 , fly ash 680kg / m 3 , sisal fiber 27kg / m 3 , polycarboxylate superplasticizer 10kg / m 3 , binder hydroxypropyl methylcellulose 0.16kg / m 3 .

[0044] All the other are with embodiment 1.

Embodiment 3

[0046] Modify the raw material formula of sisal fiber cement-based composite material to: water 300kg / m 3 , 42.5 grade ordinary Portland cement 330kg / m 3 , fine sand 700kg / m 3 , fly ash 700kg / m 3 , sisal fiber 28kg / m 3 , polycarboxylate superplasticizer 15kg / m 3 , binder hydroxypropyl methylcellulose 0.17kg / m 3 .

[0047] All the other are with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com