Tailoring and storing equipment for elastic linen-like polyester-viscose fabric with high verticality

A polyester-viscosity, high-strength technology, applied in the field of cutting equipment, can solve the problems of operators such as troublesome cutting, irregular cutting, and reduced work efficiency, and achieve the effect of convenient replacement of winding rollers and easy storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

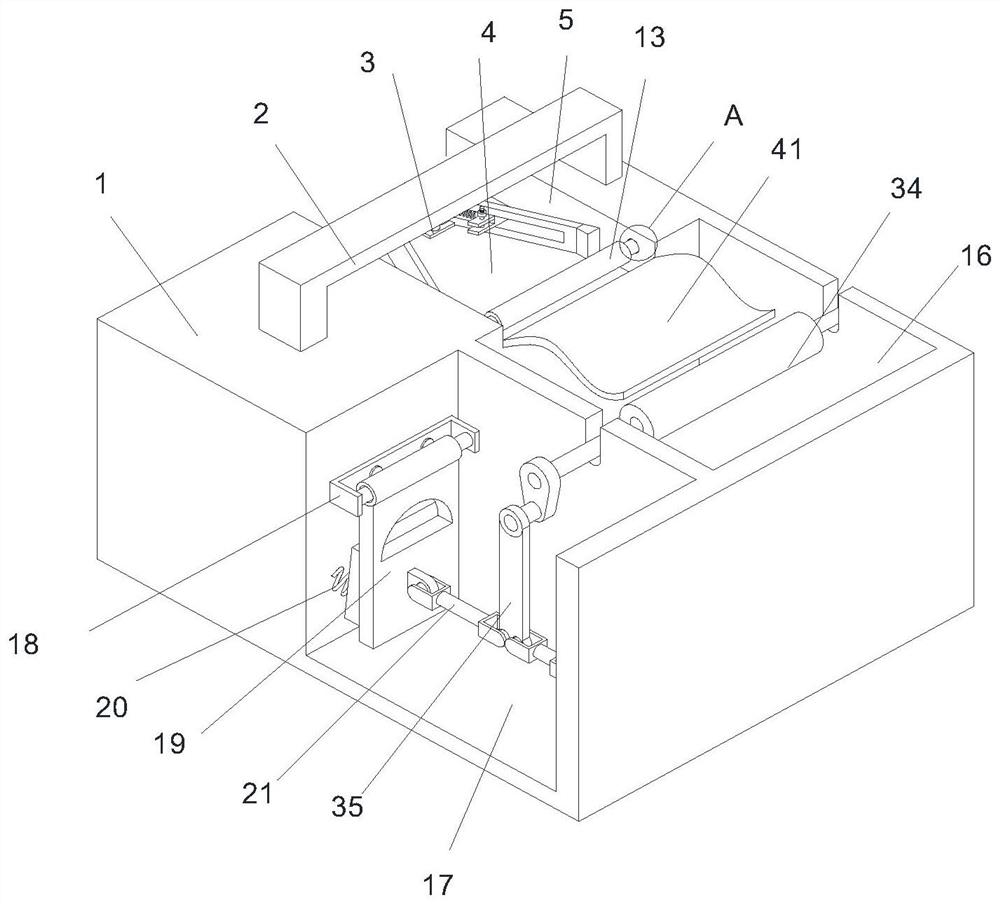

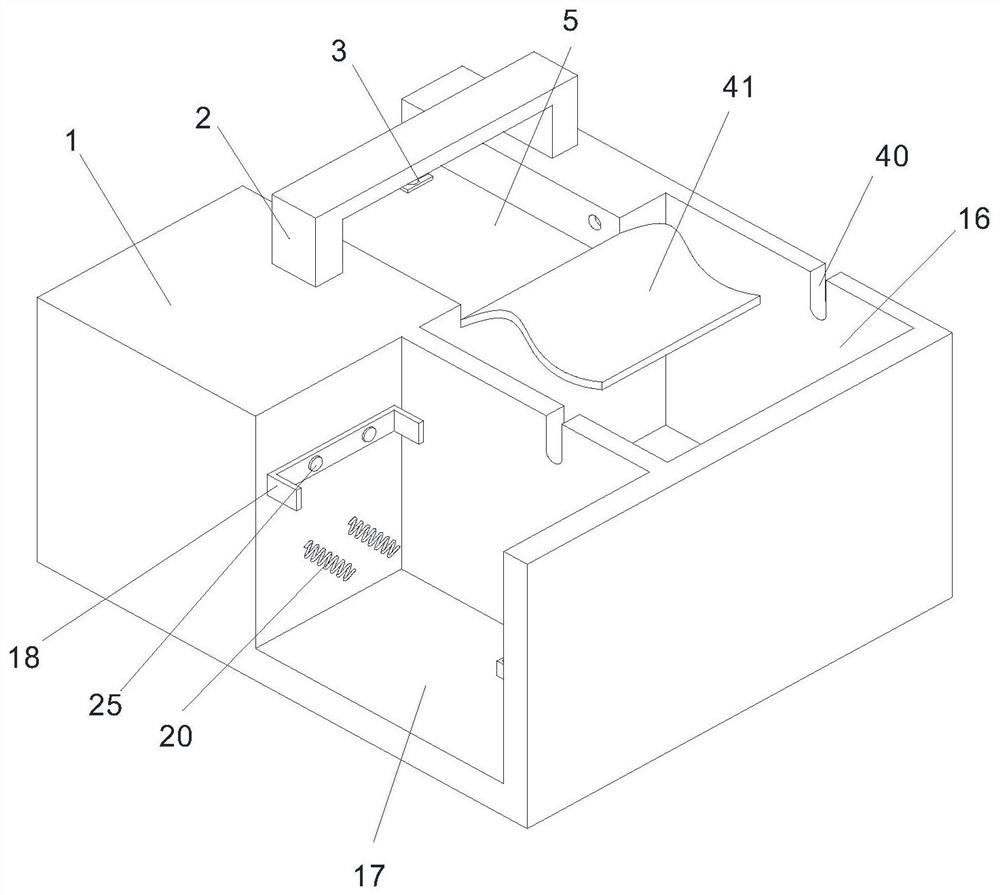

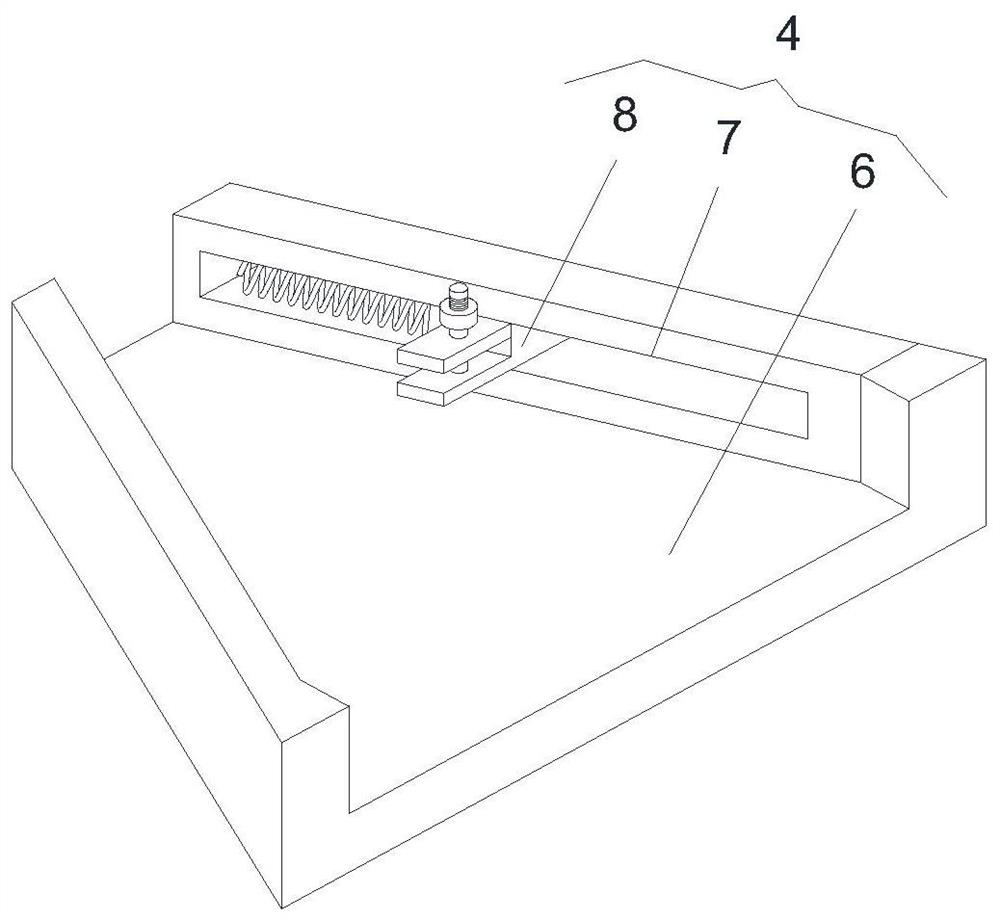

[0032] Embodiment: the cutting storage equipment of highly vertical polyester viscose imitation hemp elastic fabric, such as Figure 1-Figure 7As shown, the cutting machine 1 is included, and the cutting tool holder 2 is fixedly installed on the cutting machine 1, and the lower wall surface of the cutting tool holder 2 is fixedly installed with a cutting knife 3 for cutting cloth. The cutting knife 3 is an existing structure, and will not be repeated here. , the upper wall of the cutting machine 1 is provided with a fixing groove 5, the fixing groove 5 is a rectangular groove, and the inner hollow area of the fixing groove 5 communicates with the front wall of the cutting machine 1, and it is characterized in that: the fixing groove 5 is fixedly installed with a The stretching device 4 of cloth, stretching device 4 comprises: cloth board 6, movable groove 7 and movable block 8, the cross section of cloth board 6 is trapezoidal, and the diameter of cloth board 6 becomes larger...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com