Method for preparing large-area single-layer colloidal crystal based on water film

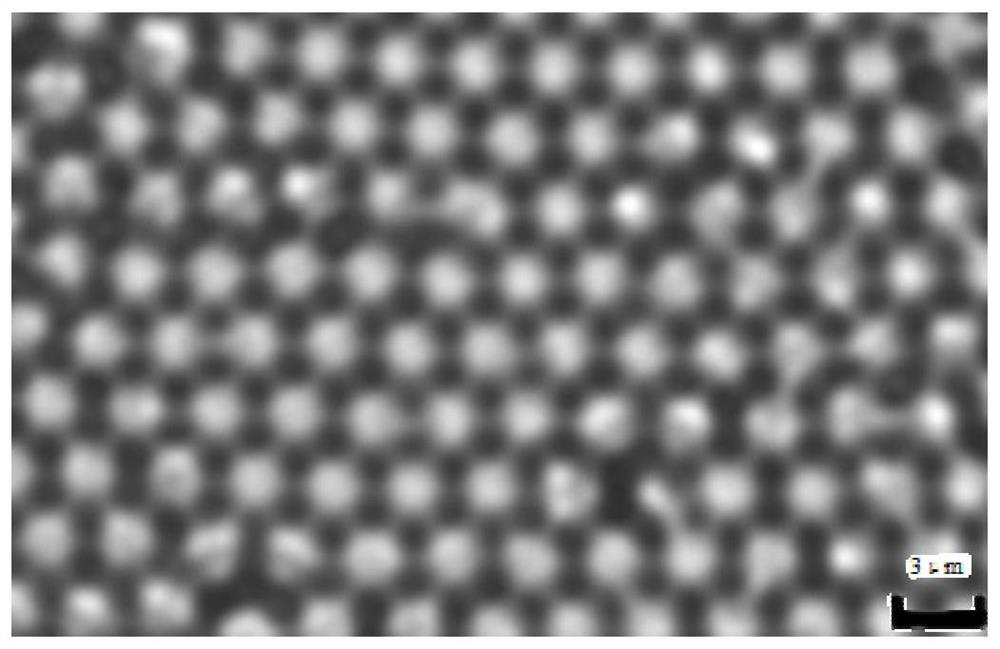

A single-layer colloidal crystal, large-area technology, applied in the field of colloid science, can solve the problems of destroying the periodicity of surface potential energy, poor microscopic order in large areas, and large coverage of agglomerated particles, and achieve good micro-ordering in large areas, The effect of reducing surface coverage and low coverage of agglomerated particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further specifically described below through example implementation and accompanying drawings.

[0034] Step 1. Clean two 20*20mm silica substrates and Petri dishes separately, then soak them in alcohol with a concentration higher than 75% for 5 minutes, then place them in ultrapure water for 5 minutes and repeat the above cleaning for 2-3 times , so that both the front and back sides exhibit super-hydrophilic properties;

[0035] Step 2. Vibrate the monodisperse solution of silica colloidal particles with a radius of 1.01 μm in an ultrasonic instrument for 5 minutes to disperse as much as possible and reduce clusters;

[0036] Step 3. Place the petri dish on a horizontal test bench, and place a piece of substrate from step 1 in the center of the petri dish;

[0037] Step 4. Drop 50 microliters of ultrapure water in the center of the substrate in step 3 to form a water film on the surface of the substrate;

[0038] Step 5. Place the subst...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com