Muck improvement material for earth pressure balance jacking pipe in anhydrous sand layer

An earth pressure balance and slag improvement technology, applied in soil conditioning materials, applications, earthwork drilling and other directions, can solve problems such as poor slag improvement effect, difficulty in soil dumping in soil tanks, and easy occurrence of uplift, etc., and achieves poor water retention, Poor flow plasticity and the effect of increasing cohesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

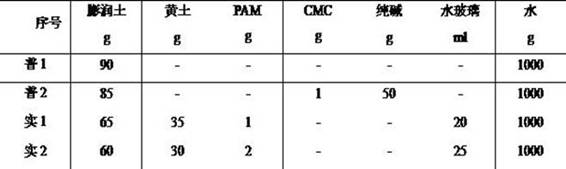

Examples

Embodiment Construction

[0047] In order to make the purpose, technical solutions and advantages of the embodiments of the present invention more clear, the embodiments of the present invention will be further described in detail below in conjunction with the embodiments. Here, the exemplary embodiments and descriptions of the present invention are used to explain the present invention, but not to limit the present invention.

[0048] It is to be understood that the terms "comprising / comprising", "consisting of" or any other variation thereof are intended to cover a non-exclusive inclusion such that a product, apparatus, process or method comprising a set of elements includes not only those elements , and may include other elements not expressly listed, or elements inherent in the product, apparatus, process or method, as required. Without further limitations, an element defined by the phrase "comprising / comprising...", "consisting of... does not exclude the presence of additional the same elements. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com