UV-cured high-surface-tension gloss oil and preparation method and application thereof

A technology with high surface tension, applied in coatings, paper coatings, textiles and papermaking, etc., can solve problems such as difficult adhesion and poor recoatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] The present invention also provides a kind of preparation method of above-mentioned UV curing high surface tension varnish, comprising the following steps:

[0028] A) mixing the modified acrylic resin, the polyurethane acrylic resin and the photoinitiator, and stirring evenly to obtain a mixture;

[0029] B) stirring and mixing the mixture with wetting aid and benzyl acrylate to obtain UV curable high surface tension varnish.

[0030] In the present invention, the type, source and amount of the modified acrylic resin, polyurethane acrylic resin, photoinitiator, wetting aid and benzyl acrylate are the same as those of the above-mentioned modified acrylic resin, polyurethane acrylic resin, The types, sources and amounts of the photoinitiator, wetting aid and benzyl acrylate are the same, and will not be repeated here.

[0031] The stirring speed of the mixture in the preparation step A) of the present invention is preferably 1000 to 1500 revolutions / min, such as 1000 re...

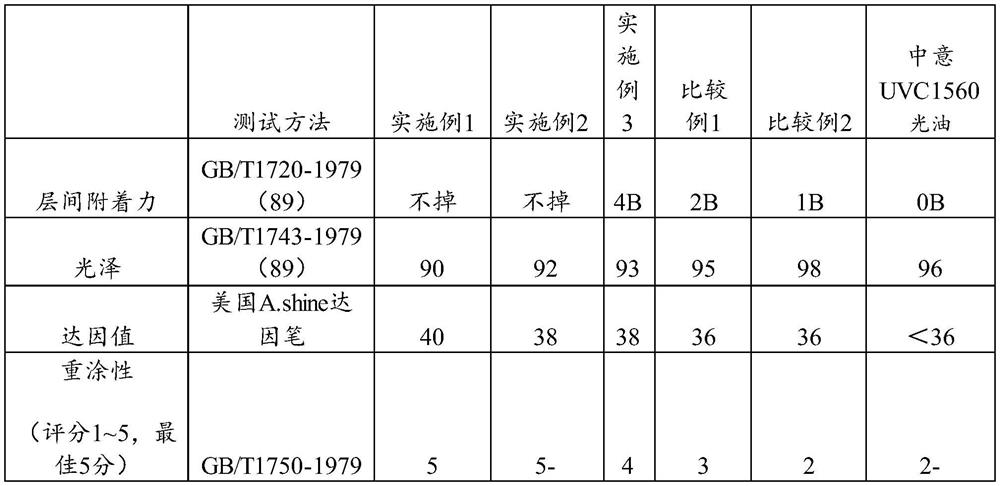

Embodiment 1

[0040] See Table 1 for the amount of raw materials.

[0041] Mix the modified acrylic resin, polyurethane acrylic resin, photoinitiator PI184 and PIBP, and stir at a machine speed of 1000 rpm for 20 minutes until the photoinitiator is completely dissolved.

[0042]Under low-speed stirring, add the wetting aid BYK3650, stir at a speed of 1000 rpm for 30 minutes, add benzyl acrylate and stir well. Filter with a 200-mesh filter screen to obtain the UV curable high surface tension varnish.

Embodiment 2~3

[0044] According to the method in Example 1 and the proportions in Table 1, a UV-curable high surface tension varnish was prepared.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com