A method for preparing carbon-based transition metal sulfide composite electrode material based on pyrolysis bio-oil

A transition metal and composite electrode technology, which is applied in the preparation/purification of carbon, chemical instruments and methods, hybrid capacitor electrodes, etc. The effect of craftsmanship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

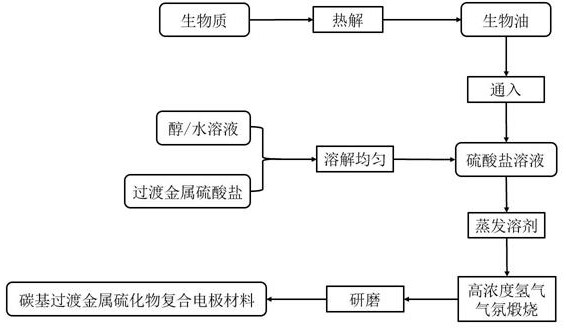

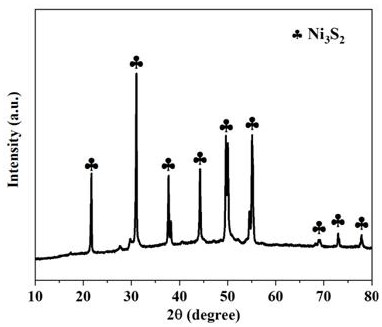

[0026] Preparation of carbon-based Ni based on bio-oil 3 S 2 / C-1-550-1 composite electrode material, including the following steps:

[0027] (1) Prepare a bio-oil absorption solution, in which the volume ratio of methanol and water is 1:2, add nickel sulfate to the absorption solution to make the mass concentration of the nickel sulfate solution 1%, and then stir with a magnetic stirrer for 40 min to make the solution. The nickel sulfate is fully dissolved evenly, and then takes 1 part of the quality of the solution and loads it into the bio-oil collecting device;

[0028] (2) Add 1 part mass of Plana sylvestris leaves into the tube furnace, connect the bio-oil collecting device, connect the bio-oil collecting device, then heat the tube furnace to 600 ℃ under nitrogen atmosphere, and keep it for 1 h;

[0029] (3) The collected bio-oil was dried in an explosion-proof blast drying oven at 80 °C for 18 h, and then the sample was transferred to a tube furnace for calcination. T...

Embodiment 2

[0031] Preparation of Ni based on bio-oil 3 S 2 / C-3-550-1 composite electrode material, including the following steps:

[0032] (1) Prepare a bio-oil absorption solution, wherein the volume ratio of methanol and water is 1:2, add nickel sulfate to the absorption solution to make the mass concentration of the nickel sulfate solution 3%, and then stir with a magnetic stirrer for 40 min to make the solution. The nickel sulfate is fully dissolved evenly, and then takes 1 part of the quality of the solution and loads it into the bio-oil collecting device;

[0033] (2) Add 1 part mass of Plana sylvestris leaves into the tube furnace, connect the bio-oil collecting device, connect the bio-oil collecting device, then heat the tube furnace to 600 ℃ under nitrogen atmosphere, and keep it for 1 h;

[0034] (3) The collected bio-oil was dried in an explosion-proof blast drying oven at 80 °C for 18 h, and then the sample was transferred to a tube furnace for calcination. The gas flow ra...

Embodiment 3

[0036] Preparation of Ni based on bio-oil 3 S 2 / C-5-550-1 composite electrode material, including the following steps:

[0037] (1) Prepare a bio-oil absorption solution, in which the volume ratio of methanol and water is 1:2, add nickel sulfate to the absorption solution to make the mass concentration of the nickel sulfate solution 5%, and then stir with a magnetic stirrer for 40 min to make the solution. The nickel sulfate is fully dissolved evenly, and then takes 1 part of the quality of the solution and loads it into the bio-oil collecting device;

[0038] (2) Add 1 part mass of Plana sylvestris leaves into the tube furnace, connect the bio-oil collecting device, connect the bio-oil collecting device, then heat the tube furnace to 600 ℃ under nitrogen atmosphere, and keep it for 1 h;

[0039] (3) The collected bio-oil was dried in an explosion-proof blast drying oven at 80 °C for 18 h, and then the sample was transferred to a tube furnace for calcination. The gas flow r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com