Nondestructive secondary machining device for composite resin well lid

A composite resin and secondary processing technology, which is applied in the field of processing and manufacturing, can solve problems such as appearance influence, height error, and safety performance cannot be guaranteed, so as to achieve the effect of not damaging the appearance and improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

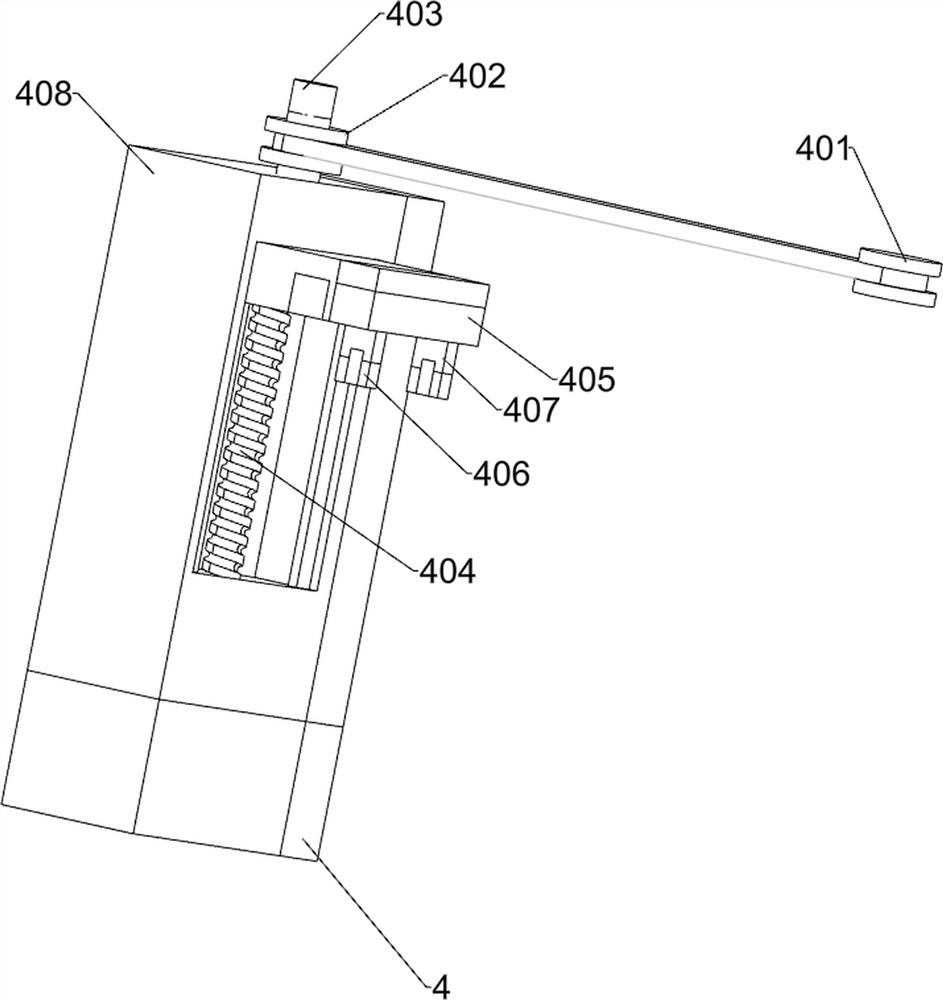

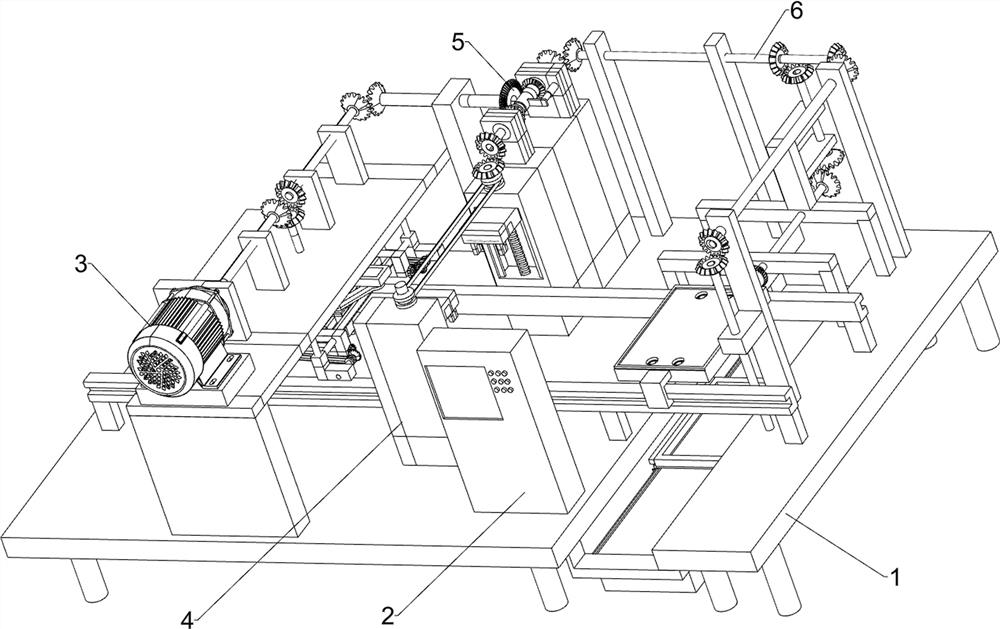

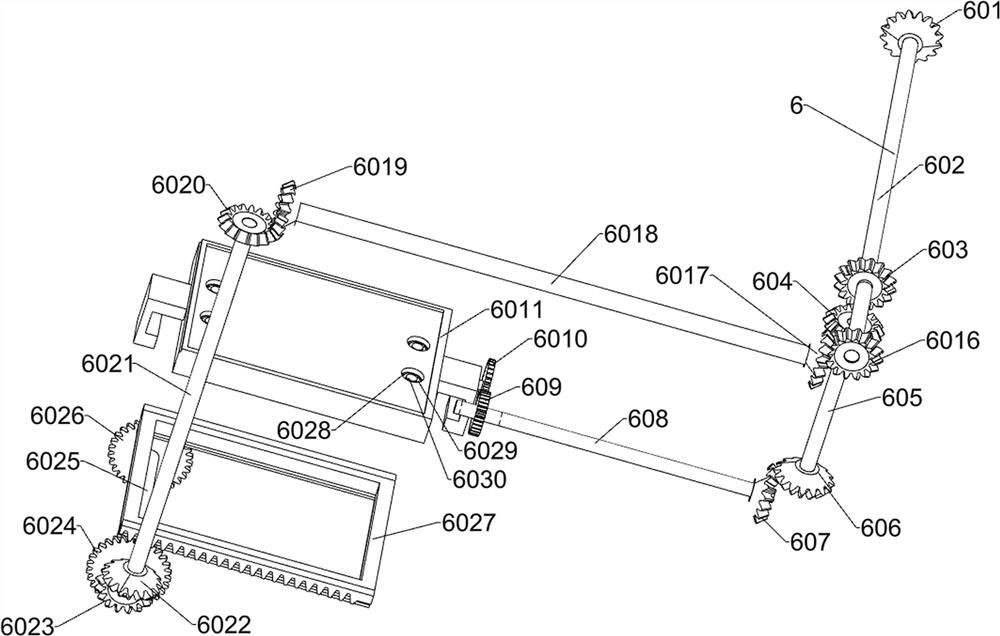

[0026]Double processed device for non-damaged resin well cover, such asFigure 1-6As shown, including a table 1, a control screen 2, a scraping assembly 3, a first handle mounting assembly 4, a second handle mounting assembly 5, and a transport test assembly 6; the table 1 is connected to the control screen 2; the workbench 1 The wiper assembly 3 is connected; the table 1 is connected to the first handle mounting assembly 4; the table 1 is connected to the second handle mounting assembly 5; the table 1 is connected to the transport test assembly 6; the blade assembly 3 and the second The handle mounting assembly 5 is connected; the first handle mounting assembly 4 is connected to the second handle mounting assembly 5; the second handle mounting assembly 5 is connected to the transport test assembly 6.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com