Honeycomb sponge processing device using extrusion friction to remove impurities

A technology of honeycomb sponge and processing device, which is applied in the direction of cleaning method using tools, cleaning method and utensils, chemical instrument and method, etc., can solve the problems of low manual operation efficiency, large number of sponges, and easy damage to honeycomb sponge, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

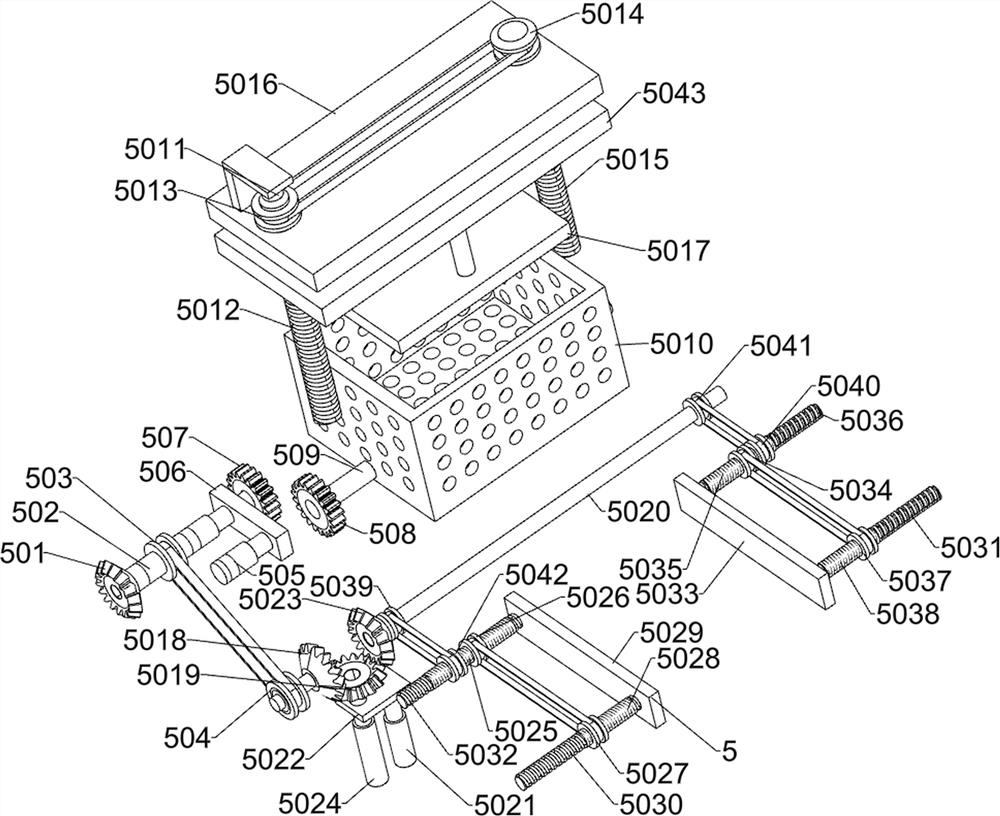

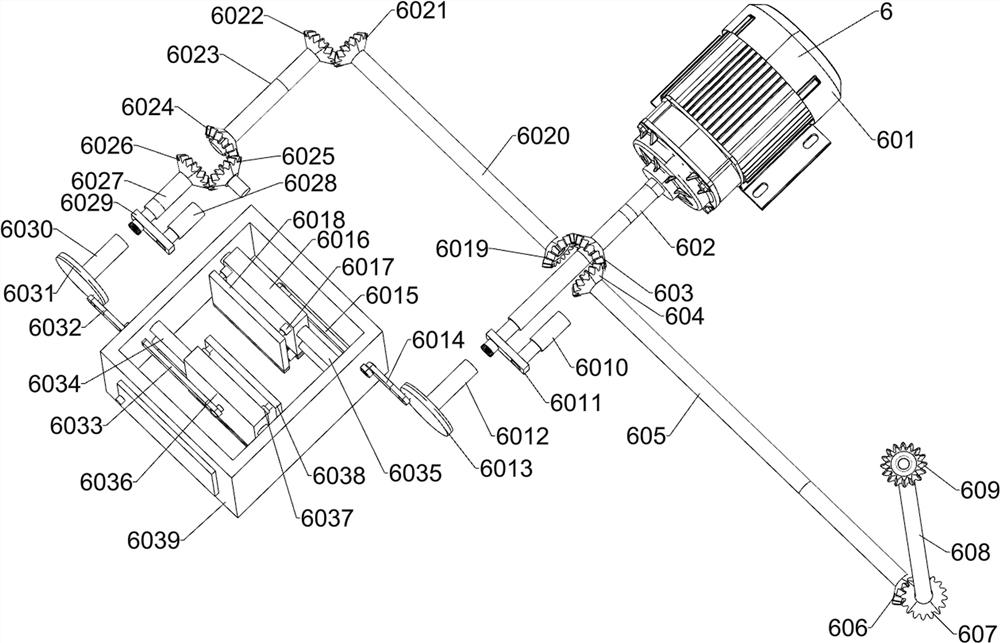

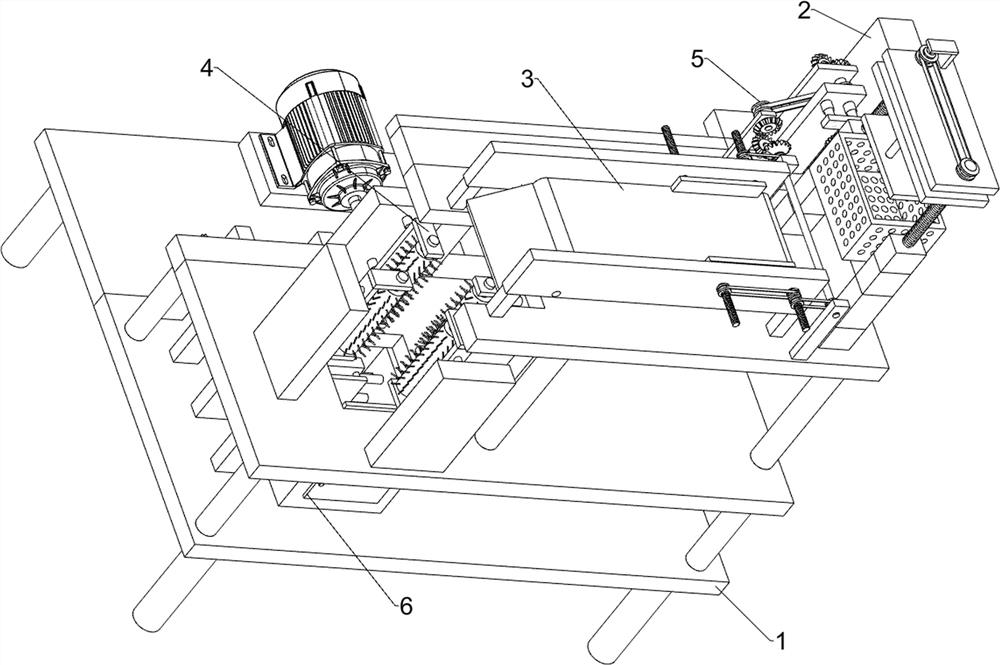

[0024] A honeycomb sponge processing device that utilizes extrusion friction to remove impurities, such as Figure 1-5 As shown, it includes workbench 1, control panel 2, transmission mechanism 3, external cleaning mechanism 4, extrusion mechanism 5 and internal cleaning mechanism 6; workbench 1 is connected with control panel 2; workbench 1 is connected with transmission mechanism 3 Connection; workbench 1 is connected with external cleaning mechanism 4; workbench 1 is connected with extruding mechanism 5; workbench 1 is connected with internal cleaning mechanism 6; transmission mechanism 3 is connected with extruding mechanism 5; external cleaning mechanism 4 An internal cleaning mechanism 6 is arranged below; the extruding mechanism 5 is connected with the internal cleaning mechanism 6 .

[0025] When the device is in use, the honeycomb sponge is first manually placed on the extrusion mechanism 5, and the device is opened and adjusted through the control panel 2, and then t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com