Profile pattern printing transfer device without multi-person operation

A transfer device and profile technology, which is applied in printing, printing machines, transfer printing, etc., can solve problems such as easy to produce wrinkles, large labor demand and physical exertion, unclear profile printing, etc., to ensure product quality, The effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

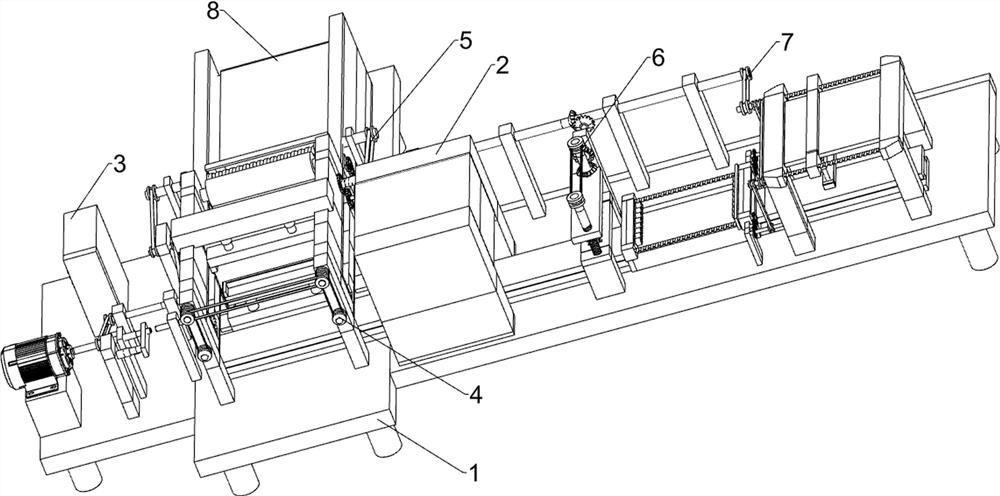

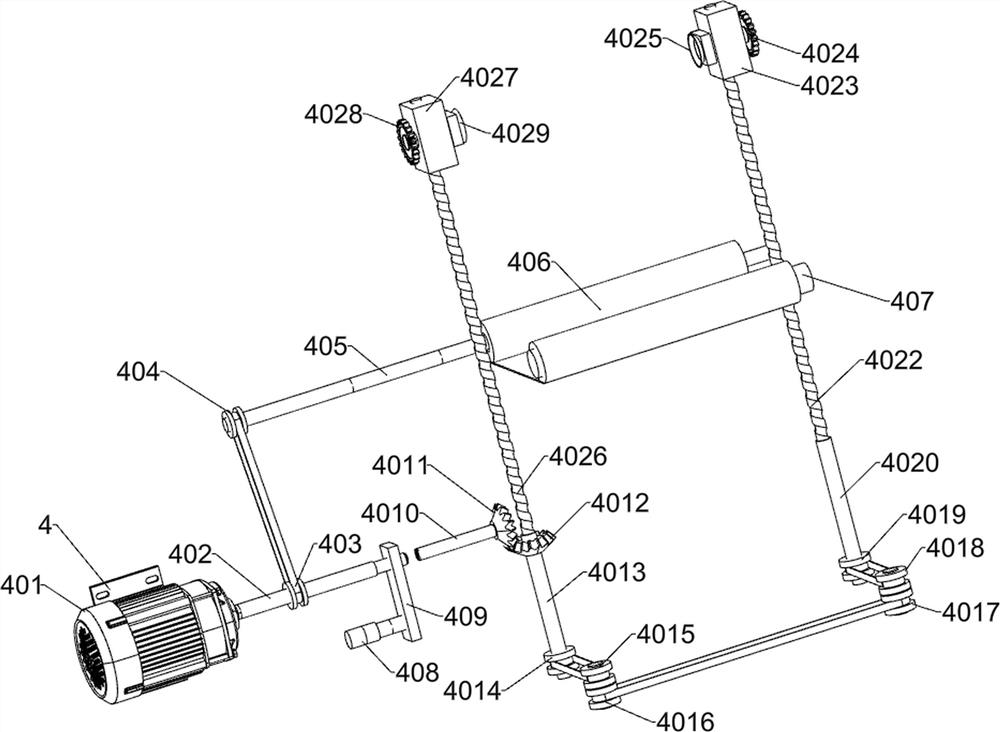

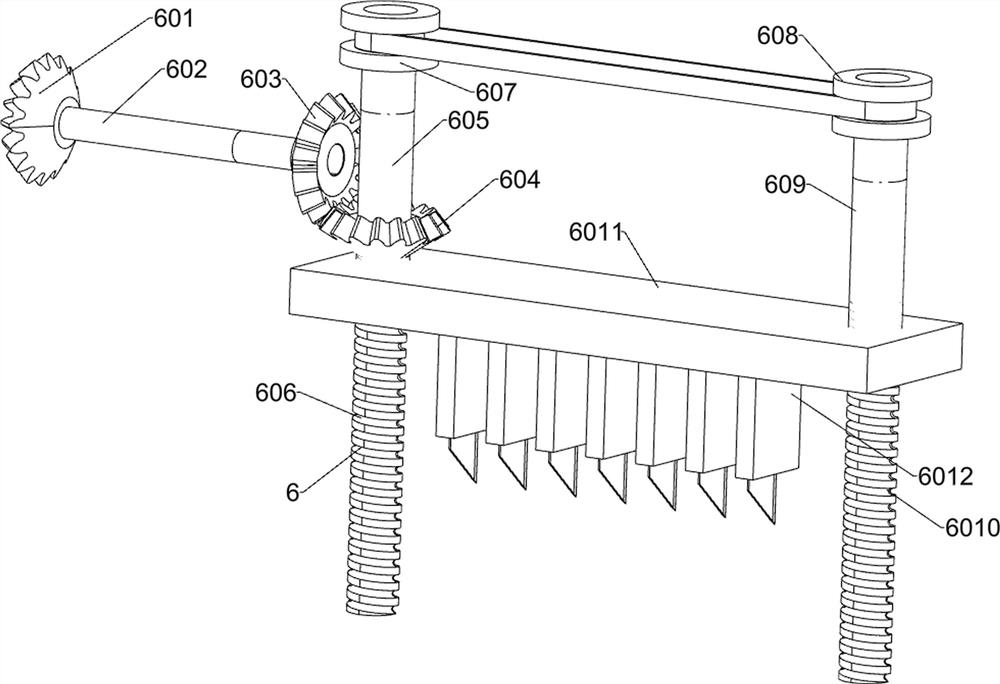

[0026] A profile printing transfer device that does not require multiple people to operate, such as Figure 1-6 As shown, it includes a workbench 1, an evacuation transfer machine 2, a control panel 3, a sealing film assembly 4, a sticker assembly 5, a cutting assembly 6, a transport assembly 7 and a conveyor belt 8; the workbench 1 is connected with the evacuation transfer machine 2; The table 1 is connected with the control panel 3; the workbench 1 is connected with the sealing film assembly 4; the workbench 1 is connected with the sticker assembly 5; the workbench 1 is connected with the cutting assembly 6; the workbench 1 is connected with the transport assembly 7; The working table 1 is connected with the conveyor belt 8; the sealing film assembly 4 is connected with the sticker assembly 5; the sticker assembly 5 is connected with the cutting assembly 6; the sticker assembly 5 is connected with the transportation assembly 7; the cutting assembly 6 is connected with the tra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com