Shearing device for automatic fluoride tester

A shearing device and measuring instrument technology, applied in grain processing, static electricity, metal processing, etc., can solve the problems of non-standard size of filter membrane, inability to achieve automatic unattended, artificial pollution, etc., to avoid the influence of human factors, The effect of convenient transportation and elimination of static electricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below in conjunction with specific embodiments.

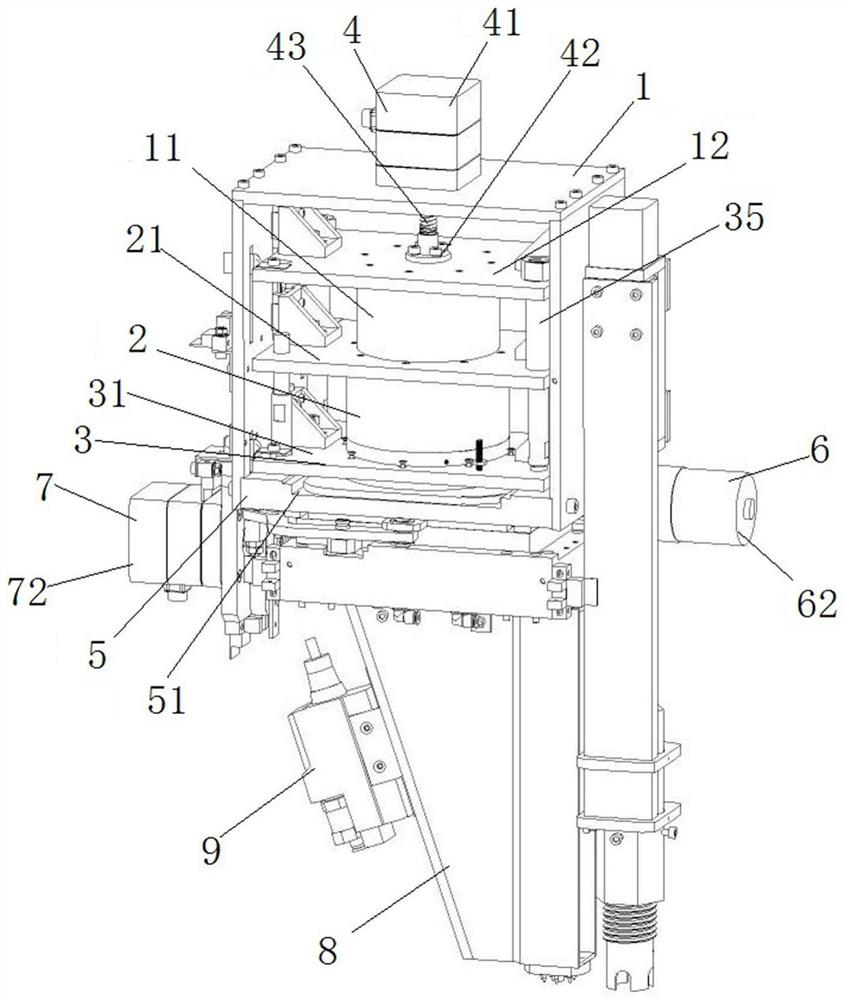

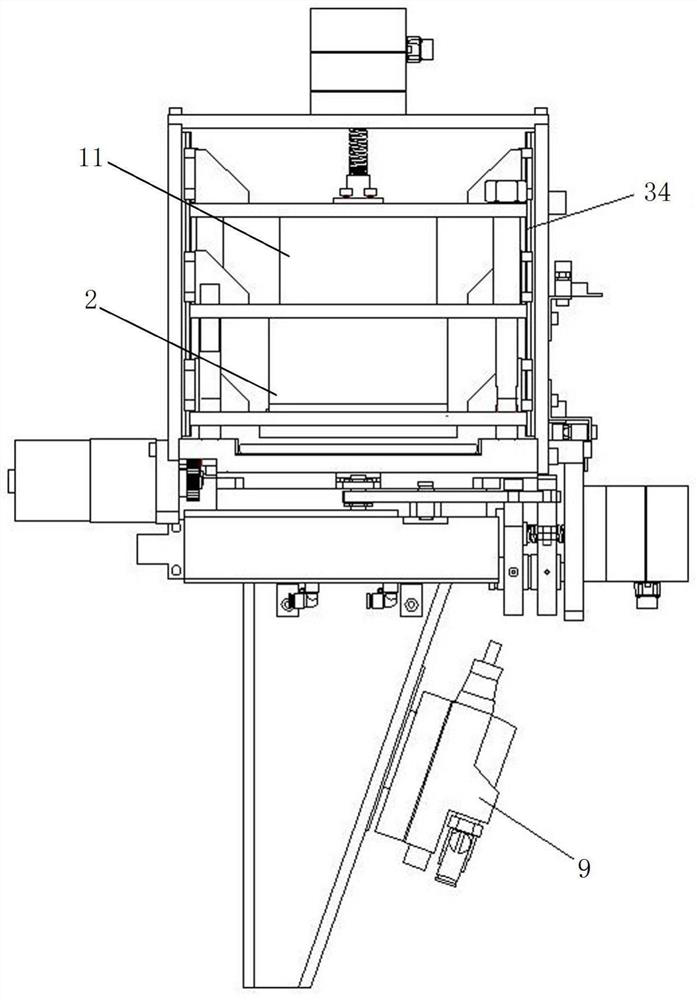

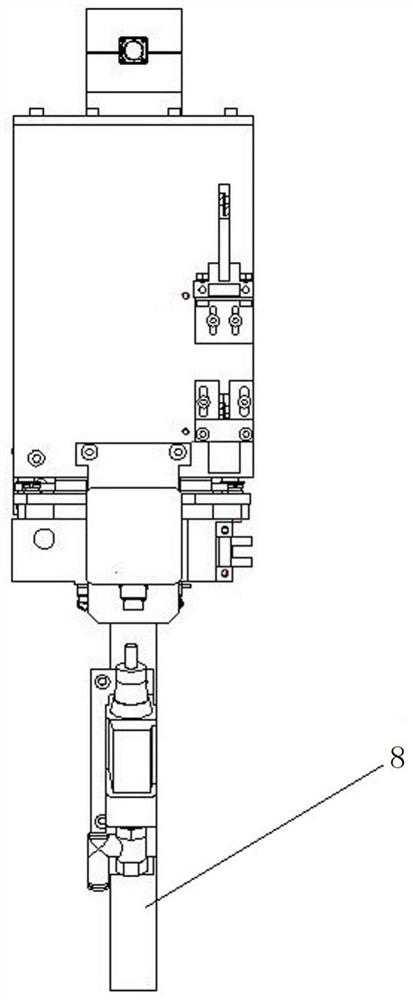

[0027] A shearing device for an automatic fluoride measuring instrument, combined with Figure 1 to Figure 6 As shown, it includes a cabinet 1, a film holding plate 5, a presser 3, a circle cutter 2, a push template 11, a driving mechanism 4 and a paper shredding mechanism 7.

[0028] The chassis 1 is configured in a frame shape and is hollow inside. The casing 1 is provided with a film holding plate 5 , a compactor 3 , a circular cutter 2 and a push template 11 .

[0029] The membrane holding plate 5 is used to accommodate the pushed filter membrane holder, and the membrane holding plate 5 is provided with a circular leak hole that is compatible with the circular cutting knife 2 and can make the cut filter membrane fall out. The top of the membrane holding plate 5 is provided with a filter membrane holding groove 51, and the filter membrane holding groove 51 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com