Centering tool for machining large diameter pinwheel pin holes

A large-diameter, tooling technology, used in positioning devices, metal processing equipment, metal processing machinery parts, etc., can solve the problem of uneven indexing of tooth holes along the indexing circle, low precision of wheel body concentricity, and vibration of equipment during operation. problem, to achieve the effect of convenient positioning, convenient workpiece clamping, and ensure the clamping accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Specific embodiments of the present invention will be described in detail below. It should be understood that the specific embodiments described herein are only used to illustrate and explain the present invention, but not to limit the present invention.

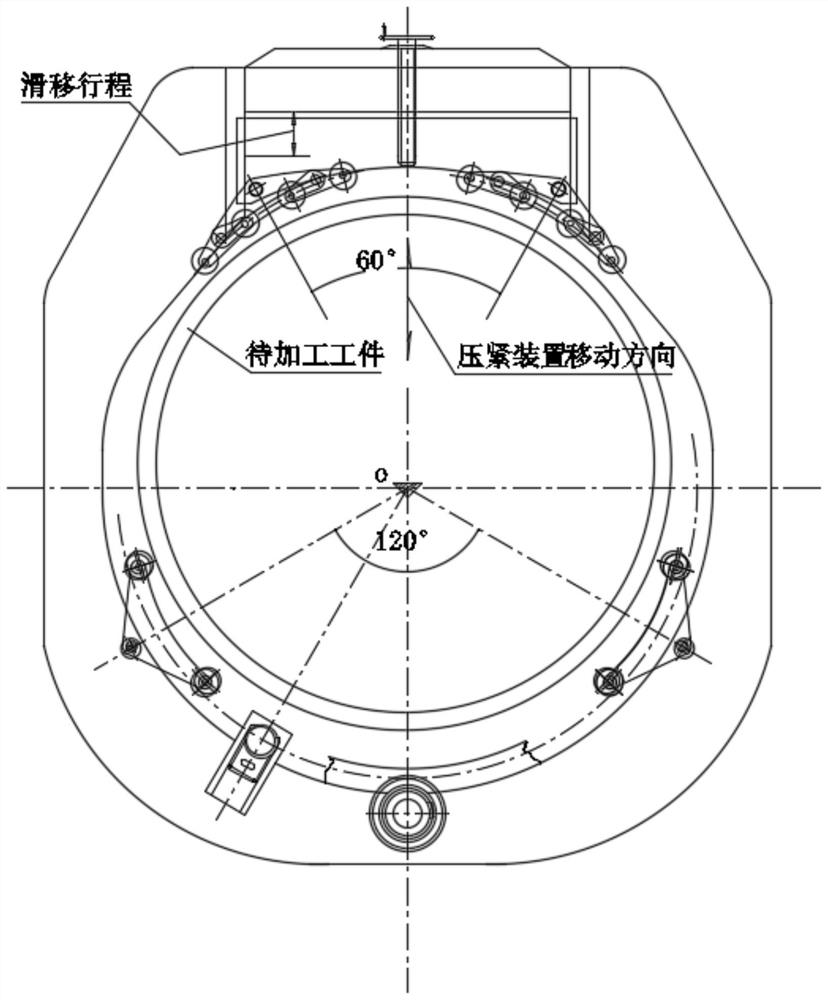

[0023] figure 1 and figure 2 An embodiment of the centering tool for processing large-diameter pin wheel pin holes of the present invention is shown. The centering tool includes a fixed circular center platform 1, a rotary frame 3, a vertical rotary drive device 4, a pressing device 2 and a positioning device. Component 5. The fixed circle center platform 1 is used as a tooling body, which is fixedly installed on the processing site and used for clamping workpieces. The outer circle of the fixed center platform 1 is provided with a large gear. The pressing device 2 and the positioning assembly 5 are installed on the rotary frame 3. The pressing device 2 and the positioning assembly 5 are respectively located on op...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com