Angular contact ball bearing outer ring forge piece profiling plate and method for machining outer ring forge piece

A technology for forgings of angular contact ball bearings and outer rings, which is applied in the field of profiling plates and forgings of outer rings of angular contact ball bearings, and can solve the problems of difficult processing procedures, low production efficiency, waste of raw materials, etc. Difficulty of processing procedures, improvement of production efficiency, and effect of ensuring product accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

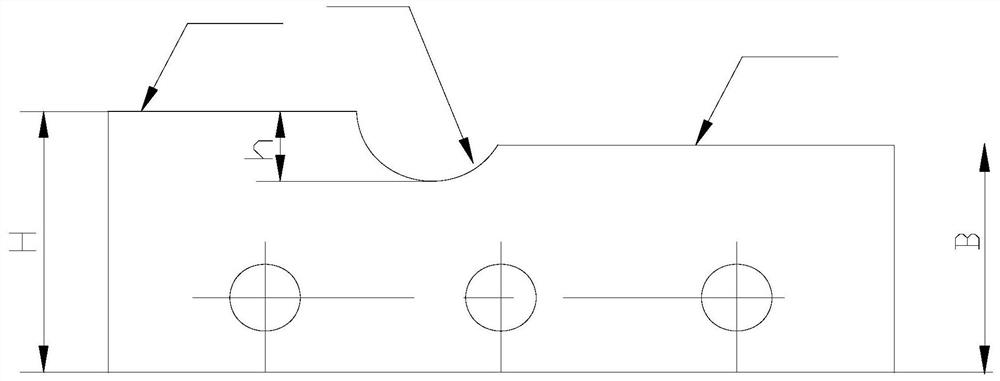

[0037] Specific implementation mode one: combine image 3 Describe this embodiment, the profiling plate of the angular contact ball bearing outer ring forging, the profiling plate is a rectangular plate body, the middle part of one side of the rectangular plate body is provided with an arc-shaped notch 1, and the left side of the arc-shaped notch 1 is a plane 2. The right side of the arc-shaped notch is plane 3, and plane 2 is parallel to plane 3. There are multiple through holes on the profiling plate.

specific Embodiment approach 2

[0038] Specific implementation mode two: combination image 3 Describe this embodiment, the angular contact ball bearing outer ring forging profile plate, the width H of one end of the profile plate is greater than the width B of the other end of the profile plate, and the width H of the profile plate is the same as the width of the other end of the profile plate The difference of B is smaller than the depth h of the arc-shaped notch 1, and the other is the same as the first embodiment.

specific Embodiment approach 3

[0039] Specific implementation mode three: combination image 3 Describe this embodiment, the angular contact ball bearing outer ring forging profile plate, the profile plate has three through holes, and the three through holes are arranged at equal intervals, the other is the same as the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap