Processing device for shearing welded steel pipe

A technology for welding steel pipes and processing devices. It is applied in shearing devices, accessories of shearing machines, and pipe shearing devices. It can solve the problems that affect the company's production efficiency, the clamps are prone to breakage, and the clamping effect is not ideal. Impact, reducing the impact of the fixture, eliminating the effect of stress concentration points

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

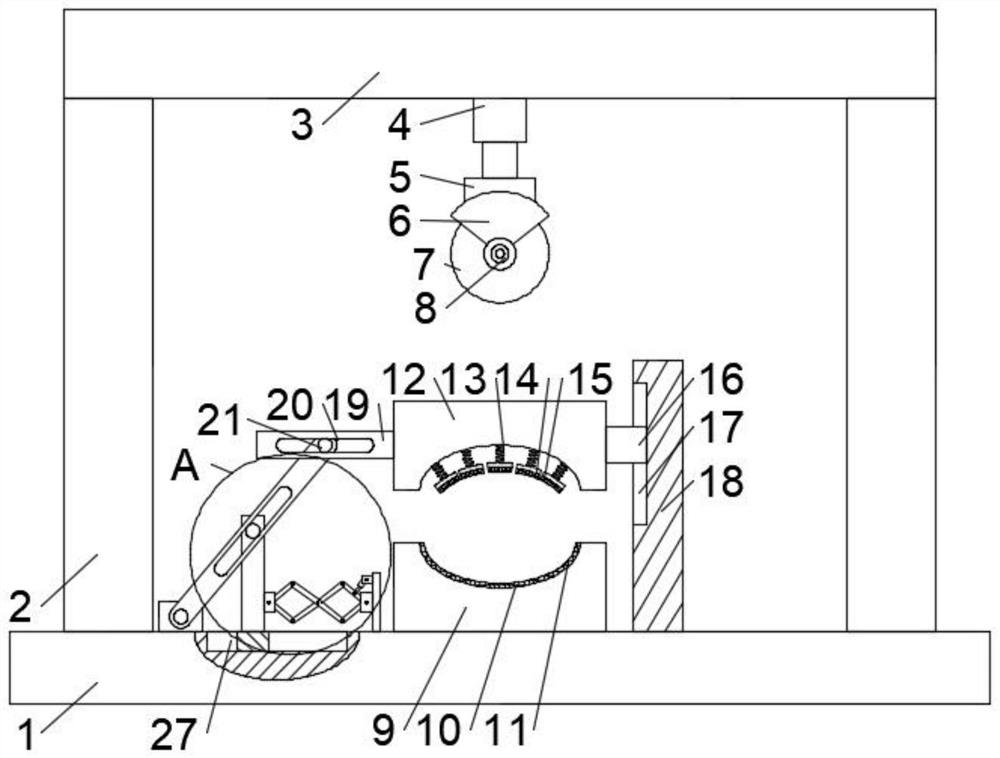

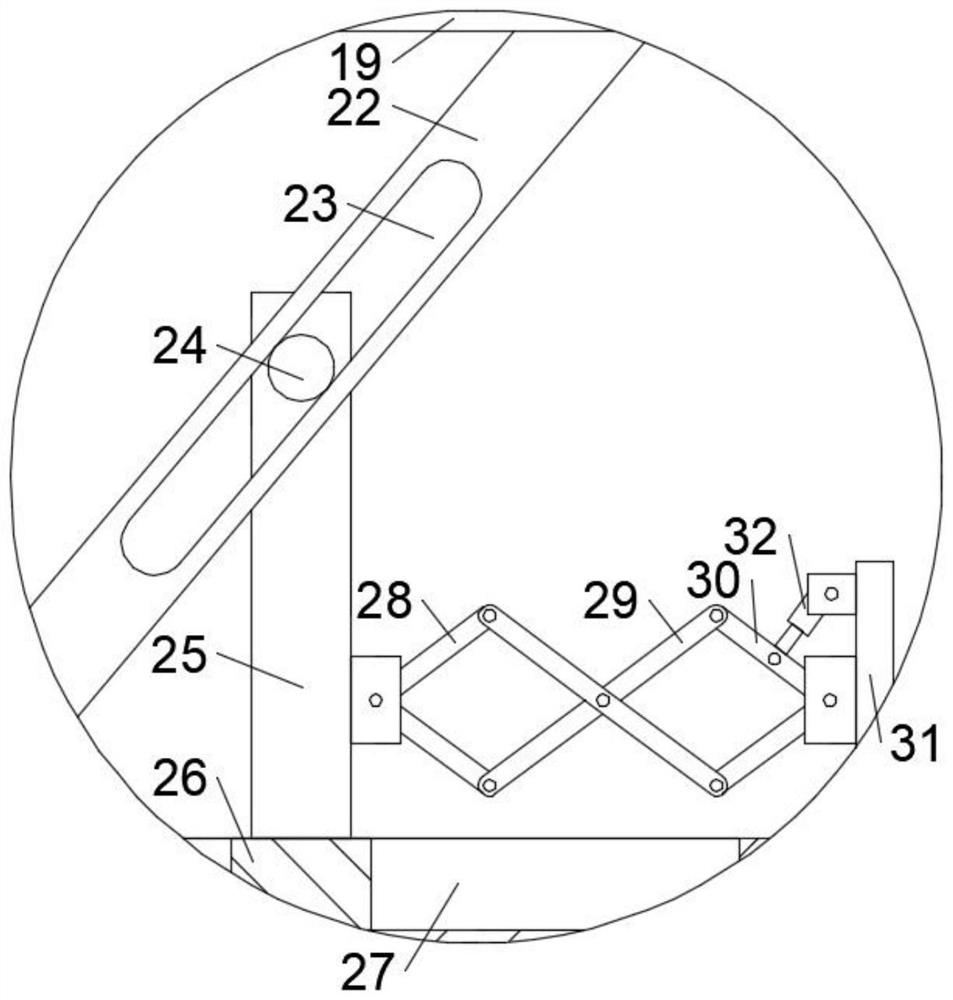

[0018] see Figure 1-2 , in an embodiment of the present invention, a processing device for shearing welded steel pipes, comprising a base 1, the surface of the base 1 is symmetrically fixedly connected with a column 2, and the ends of the column 2 are fixedly connected with a beam 3, the The bottom surface of the beam 3 is fixedly connected with a cylinder 4, and the cylinder 4 is connected with a connector 5, and the connector 5 is fixedly connected with a protective cover 6, and the protective cover 6 is rotatably connected with a cutter wheel 7, and the protective cover 6 sides are fixedly connected with a drive motor 8, a fixed block 9 fixedly connected to the surface of the base 1 is provided below the cutter wheel 7, a movable block 12 is provided above the fixed block 9, and the fixed block 9 and The side walls of the movable block 12 are provided with arc-shaped grooves 10 , and the movable block 12 is connected with a lifting assembly fixedly connected with the surfa...

Embodiment 2

[0021] see figure 1 , in an embodiment of the present invention, a first buffer pad 11 is connected to the surface of the arc-shaped groove 10 of the fixing block 9 .

[0022] In the embodiment of the present invention, the first buffer pad 11 is provided to play a buffering role, reduce the impact on the welded steel pipe during shearing, eliminate the stress acting on the welded steel pipe, avoid stress concentration, and avoid clamp fracture.

Embodiment 3

[0024] see figure 1 , in an embodiment of the present invention, several springs 13 are fixedly connected to the surface of the arc-shaped slot 10 of the movable block 12, and the other end of the spring 13 is fixedly connected to an arc-shaped plate 14, and the surface of the arc-shaped plate 14 A second buffer pad 15 is connected.

[0025] In the embodiment of the present invention, the spring 13 and the second buffer pad 15 are arranged to play a buffering role, reduce the impact on the welded steel pipe during shearing, eliminate the stress acting on the welded steel pipe, avoid stress concentration, and avoid clamp fracture , the arc-shaped plate 14 is arranged to fix the second buffer pad 15 to increase the contact area with the welded steel pipe, and the material of the arc-shaped plate 14 is rubber.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com