Device for processing discarded medical sharps envelopes

A technology of sharps and envelopes, which can be used in the direction of hypodermic injection devices, devices introduced into the body, needles, etc., and can solve problems such as inconvenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0070] Reference Figure 8 , 9 12-15, about the sleeve, the sleeve 13 of the present invention is used to wrap the needle tip portion of the sharpener.

[0071] Since PE, the PVC plastic material can be processed into a tubular body having a diameter of less than 2 mm and an inner diameter of less than 0.5 mm. Therefore, the sleeve of the present invention is made of PE, PVC material. At the same time, PE, PVC materials have appropriate elasticity, set the sleeve to be unlimited, tubular having an outer diameter of 2 mm, an inner diameter of 0.3 mm, and a needle tip 12 having an outer diameter of 0.62 mm to 0.9 mm is inserted into the sleeve 13, It can be wrapped in a needle tip by elastic tension, and does not fall, and it will not be bloated.

[0072] With PE, the PVC plastic material is processed into an outer diameter of 2 mm and an inner diameter of 0.4 mm, at least a needle having an outer diameter of 0.5 mm-1 mm in a needle.

[0073] Of course, in order to apply more specifi...

example 2

[0077] reference Figure 16-17 The envelope 18 is disposed above the left side, and the sleeve bin 17 is disposed on the right side of the envelope device 18, and the sleeve roll 16 is placed in the sleeve bin 17. The collection warehouse 14 is disposed at the bottom of the device.

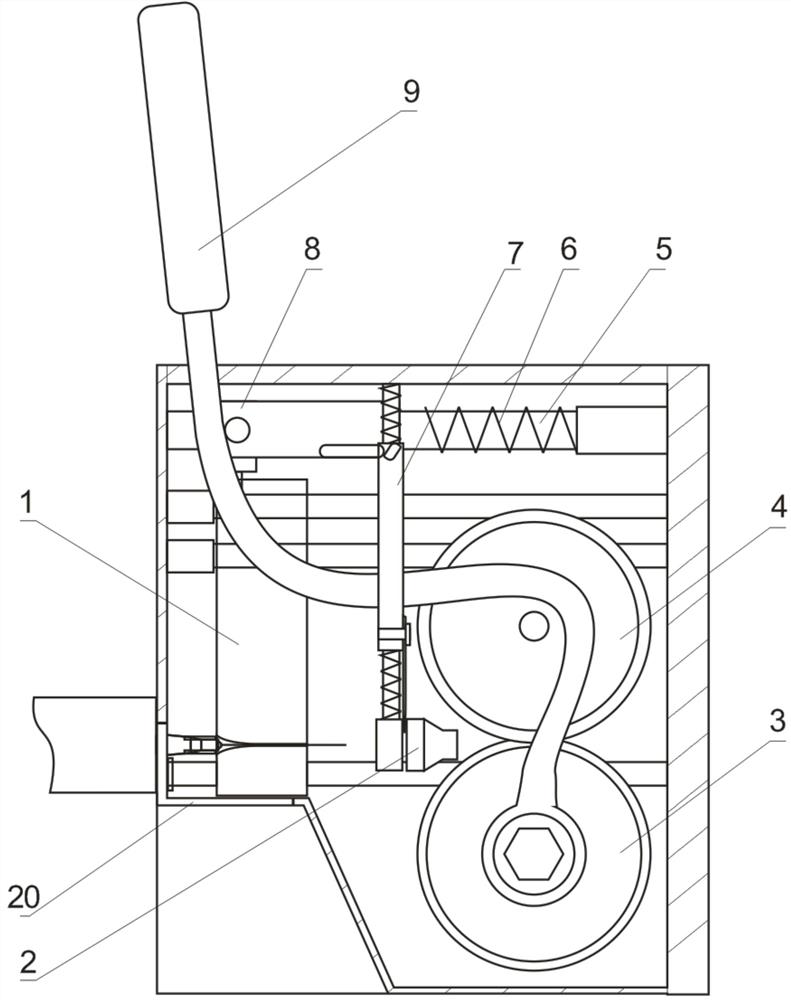

[0078] reference figure 1 , Figure 17 The housing of the envelope device 18 includes: the top casing, the bottom case, the left side close to the left shell of the jaw head 1, the right side of the conveyor wheel pair and the sleeve 17 barrier.

[0079] The warehouse of the casing 17 is the same plate with the right housing.

[0080] The warehouse wall (or the right housing) of the casing bin 17 is provided with a third vent that is pulled into the conveying wheel pair.

[0081] When the sleeve is used, the sleeve is needed to enter the casing 17, and the bushing is inserted into the envelope 18, so it is necessary to set the sleeve 17 to detachable, to the envelope device 18 During the process of pass...

example 3

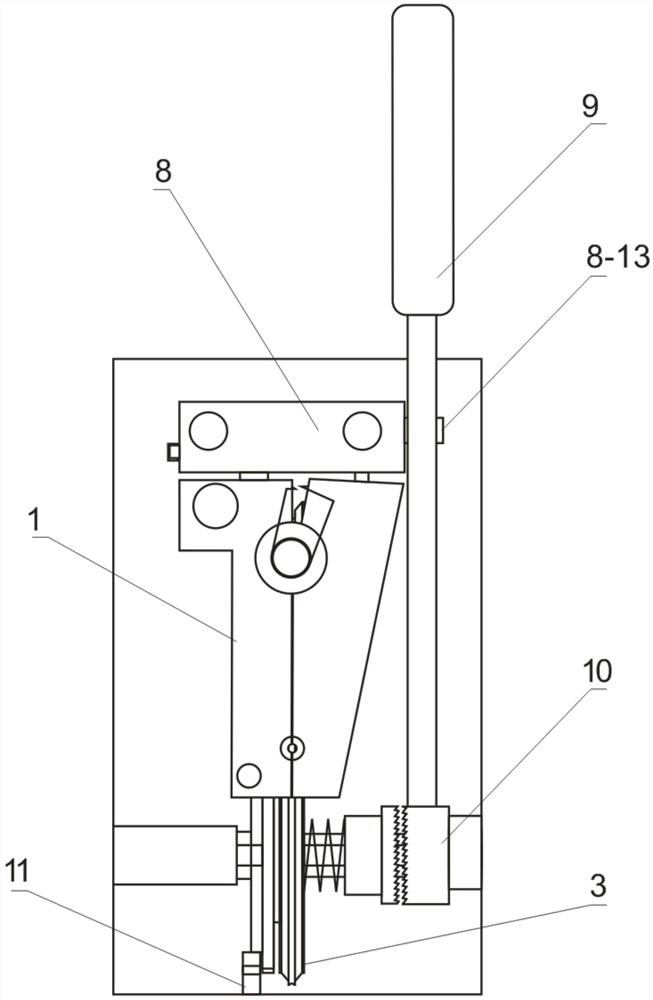

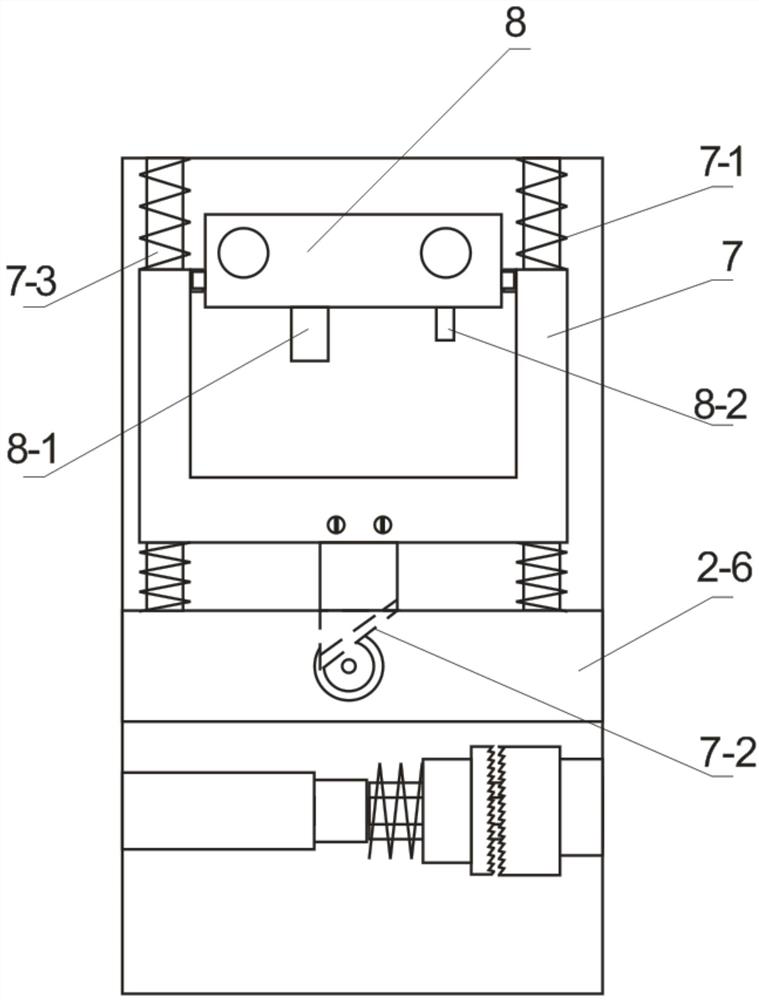

[0086] reference figure 2 , Figure 5-6 The clamp head 1 is disposed longitudinally, and the first jaw head 1-2 of two generally rectangular cubes is constituted with the second clamp head 1-1. The clamp head 1 can use nylon plastic or an aluminum alloy. Because the clamp head 1 is the moving part, it is better to use stainless steel to extend the service life of the equipment, taking into account wear. When using nylon plastic and aluminum alloys, it is necessary to add stainless steel sleeve in the wear area, such as adding stainless steel sleeve, first groove 8-6 and first groove 8-6 with the clamp head slide. The stainless steel sleeve is installed.

[0087] The clamp head 1 is 100 mm to 120 mm, and the thickness (from the surface near the surface of the left housing to the surface of the positioning sleeve 2) is 25 mm to 35 mm.

[0088] The first clamp head 1-2 is hinged from the lower end from the lower end to about 3 / 4 from the lower end. Figure 7 The hinge center is a first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com