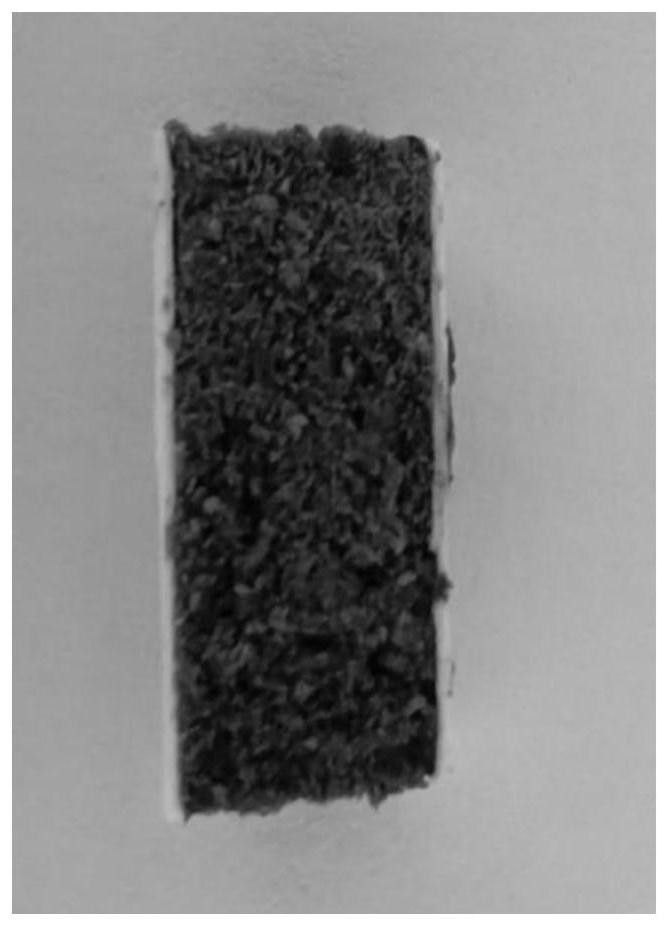

A kind of plant polysaccharide aerogel heating non-combustion flavor smoke generating material and preparation method thereof

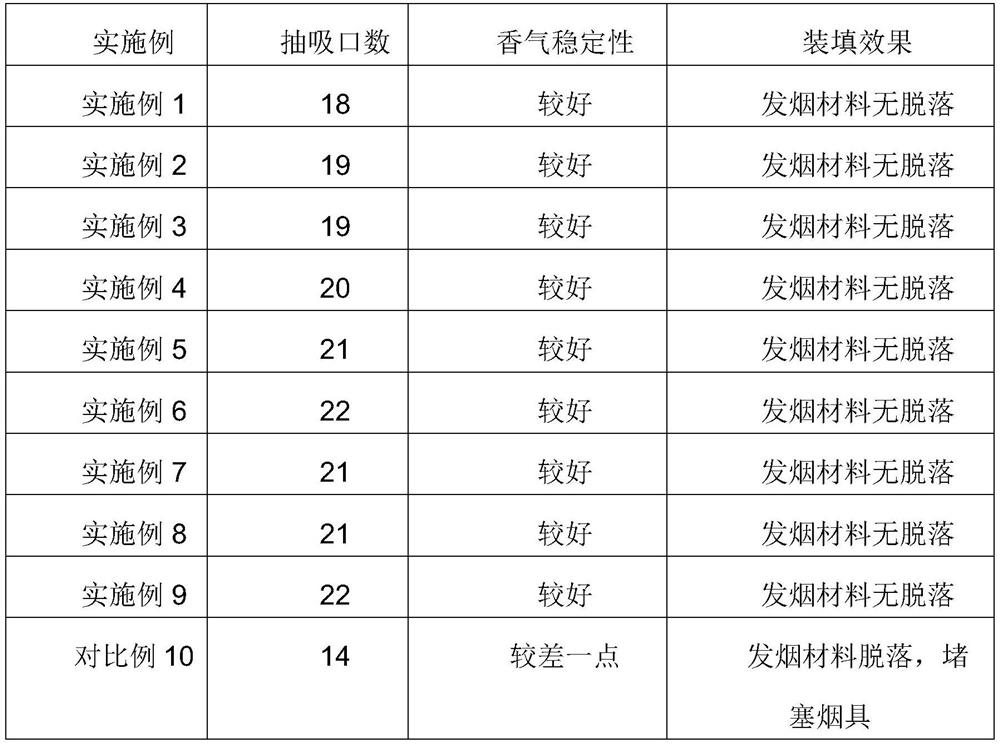

A heating non-combustion, plant polysaccharide technology, applied in the field of tobacco, can solve the problems of high cost, low production efficiency, unstable suction resistance in the flavor smoke section, etc., and achieves good overall stability, and the effect of slow release of smoke and flavor is uniform.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

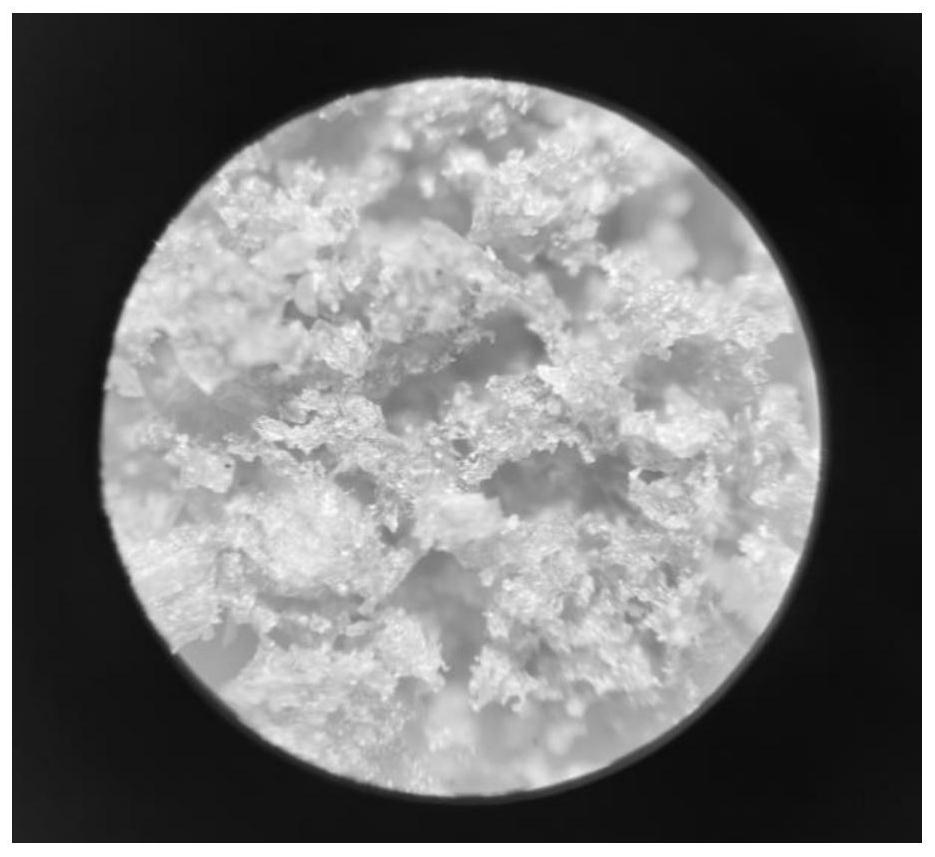

[0038] A preparation method of plant polysaccharide aerogel heating non-combustion flavor smoke generating material is prepared according to the following steps:

[0039] (1) Weigh 30 parts of tobacco leaf particles, 10 parts of propylene glycol and glycerin mixture, 5 parts of peppermint flavor, 1 part of konjac glucomannan and 60 parts of water by weight.

[0040] Among them, the mesh number of tobacco leaf particles is 100 meshes. The ratio of propylene glycol to glycerol is 1:1.

[0041](2) The weighed konjac glucomannan was added to the water while stirring, the rotating speed was 400rpm, the stirring time was 30min, and the heating temperature was 60°C. After the skeleton material is fully dispersed and the swelling is complete, the tobacco leaf particles are added while stirring. After the tobacco leaf particles are completely dispersed in the glue, continue stirring, stop heating, and cool the mixture by means of an ice-water bath.

[0042] (3) When the temperature ...

Embodiment 2

[0049] A preparation method of plant polysaccharide aerogel heating non-combustion flavor smoke generating material is prepared according to the following steps:

[0050] (1) Weigh in parts by weight 35 parts of tea granules, 15 parts of a 1:2 mixture of propylene glycol and glycerol, 10 parts of sweet orange essence, 2 parts of potato starch and 80 parts of water.

[0051] Among them, the mesh number of tea particles is 100 meshes. The ratio of propylene glycol to glycerol is 1:2.

[0052] (2) Add the weighed potato starch granules into water while stirring, the rotating speed is 300rpm, the stirring time is 20min, and the heating temperature is 90°C. After the skeleton material is fully dispersed and the swelling is complete, tea particles are added while stirring. After the tea particles are completely dispersed in the glue, continue stirring, stop heating, and cool the mixture by using an ice-water bath.

[0053] (3) When the temperature of the mixed solution drops to 2...

Embodiment 3

[0060] A preparation method of plant polysaccharide aerogel heating non-combustion flavor smoke generating material is prepared according to the following steps:

[0061] (1) Weigh 40 parts of Chinese herbal medicine granules, 15 parts of propylene glycol and glycerin mixture, 10 parts of taro milk essence, 1 part of agar and 100 parts of water by weight.

[0062] Among them, the mesh number of Chinese herbal medicine granules is 160 meshes. The ratio of propylene glycol to glycerol is 1:2.

[0063] (2) Add the weighed skeleton material into water while stirring, the rotating speed is 500rpm, the stirring time is 15min, and the heating temperature is 60℃. After the skeleton material is fully dispersed and fully swollen, the Chinese herbal medicine granules are added while stirring. After the Chinese herbal medicine granules are completely dispersed in the glue, continue stirring, stop heating, and cool the mixture by means of an ice-water bath.

[0064] (3) When the tempera...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com