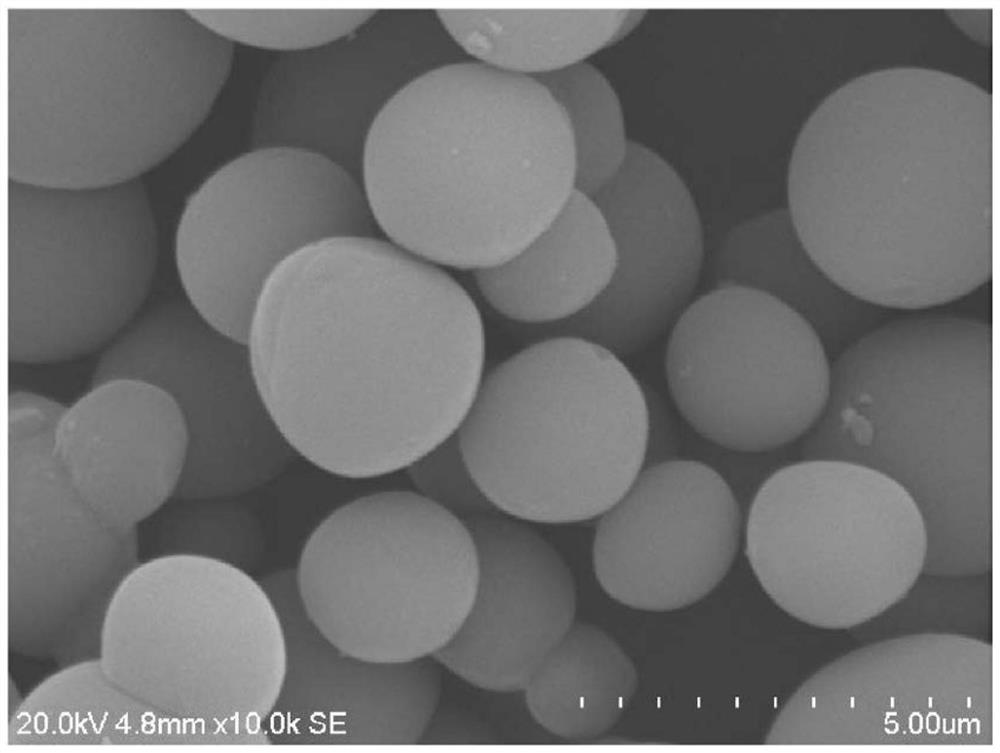

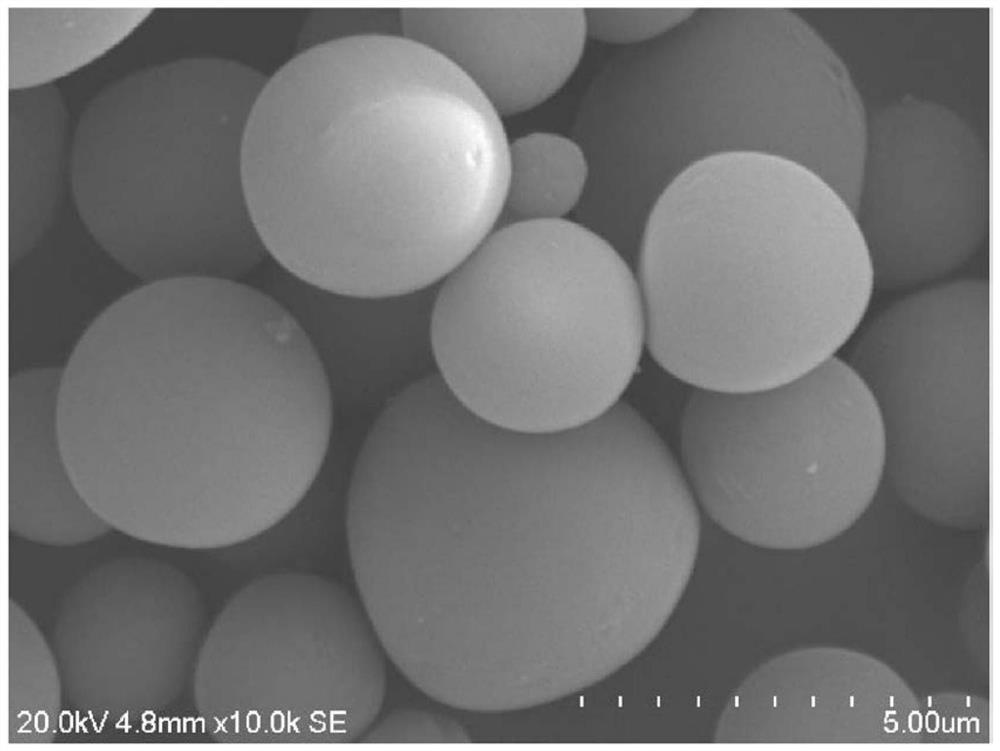

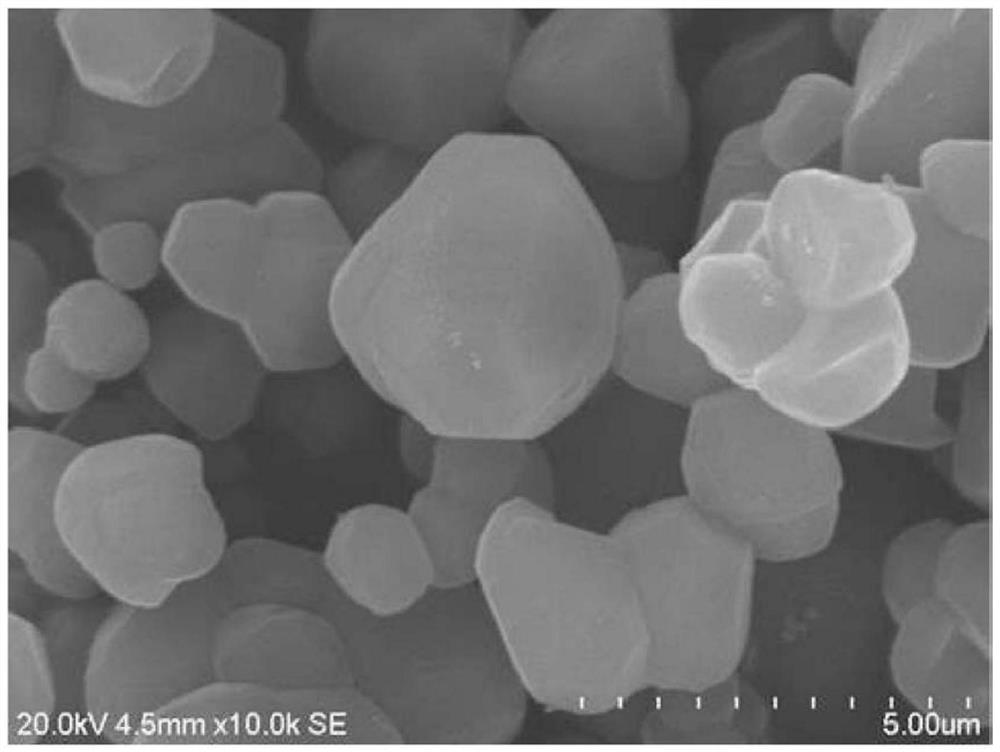

Spherical aluminum nitride powder and method for producing spherical aluminum nitride powder

A technology of aluminum nitride and spheroidization, applied in chemical instruments and methods, nitrogen compounds, inorganic chemistry, etc., can solve problems such as kneading performance and filling performance decline, particle surface area increase, particle size distribution can not be controlled, etc., to achieve promotion Effect of spheroidization and particle growth, improvement of filling properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0058] In the following, the present invention is described more specifically based on Examples and Comparative Examples, but the present invention should not be construed as being limited by these Examples.

[0059] The spherical aluminum nitride powders according to Examples 1-21 and Comparative Examples 1-5 were prepared by performing the following steps.

[0060] First, a predetermined amount of aluminum nitride raw material powder is prepared. A powder having an average particle diameter of 0.9-2.7 μm is used as the aluminum nitride raw material powder. Prepare high-purity powders of rare earth compounds and calcium compounds as additive powders. As the carbon powder, a powder having an average particle diameter of 10 to 50 nm and an ash content of 0.1% or less is used. Predetermined weight percentages of rare earth compound powder, calcium compound powder, and carbon powder were mixed into 100% by weight of aluminum nitride raw material powder. The mixing ratios of ra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com