Combined 3D spiral perforation simulation injection device and simulation method

An injection device and combined technology, which is applied in the direction of earthwork drilling, production fluid, wellbore/well components, etc., can solve the problem that the perforation injection device cannot simulate the real perforation situation, and avoid test failure, assembly and dismantling Convenience, the effect of increasing the bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Below in conjunction with accompanying drawing, the present invention will be further described:

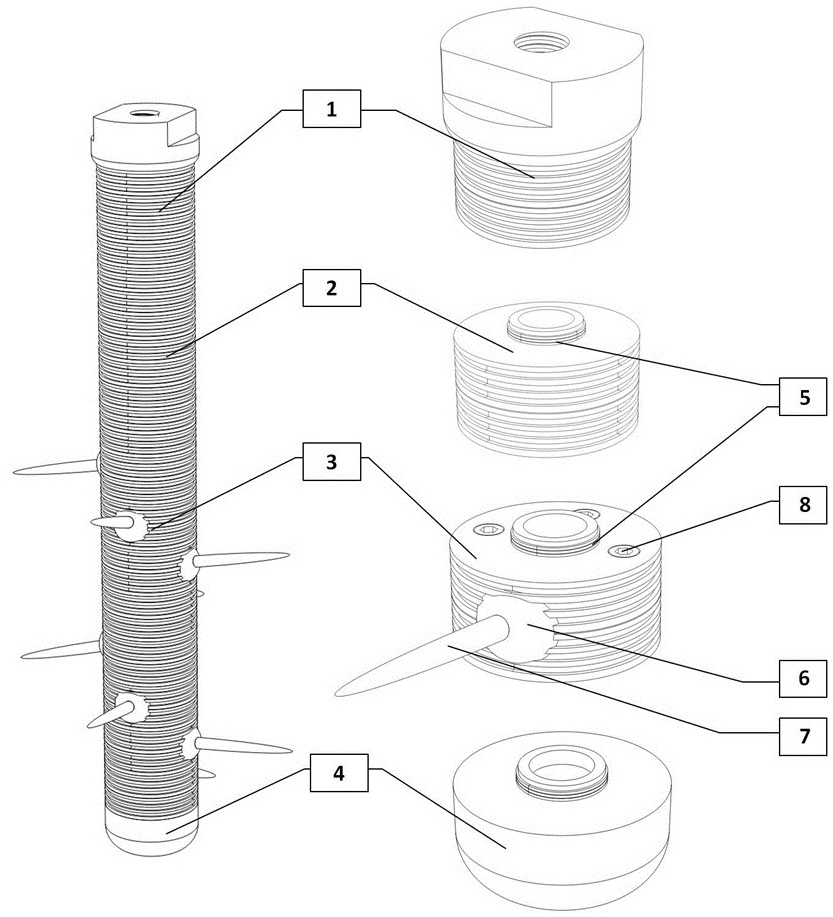

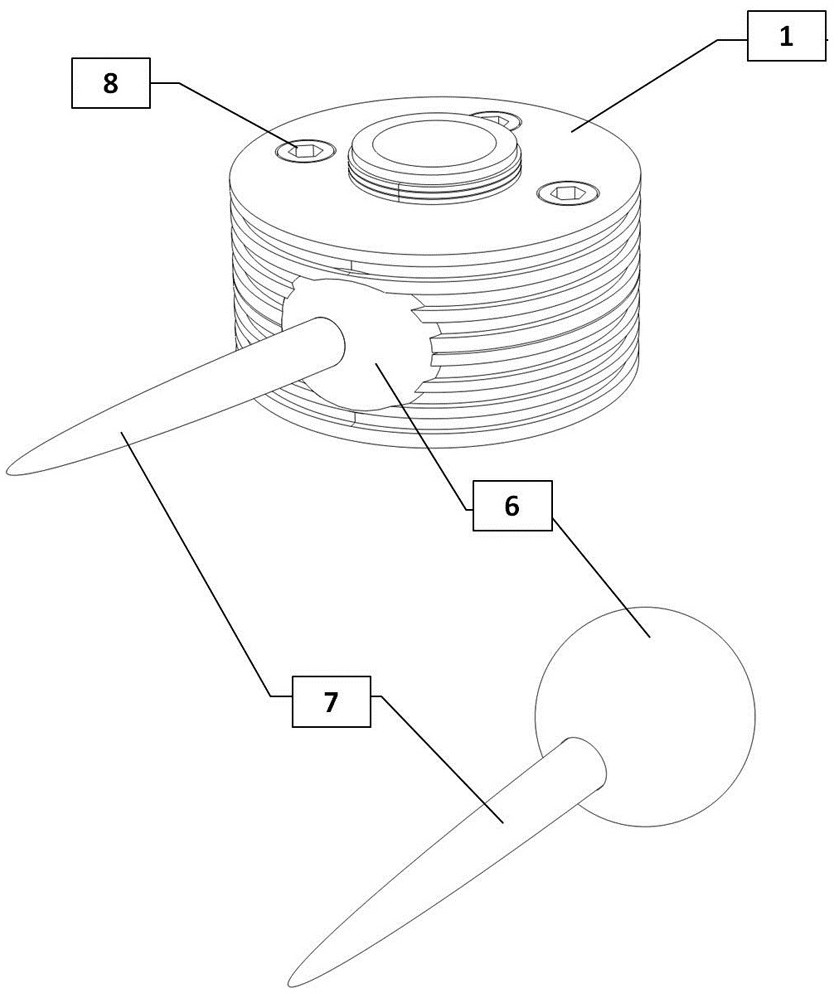

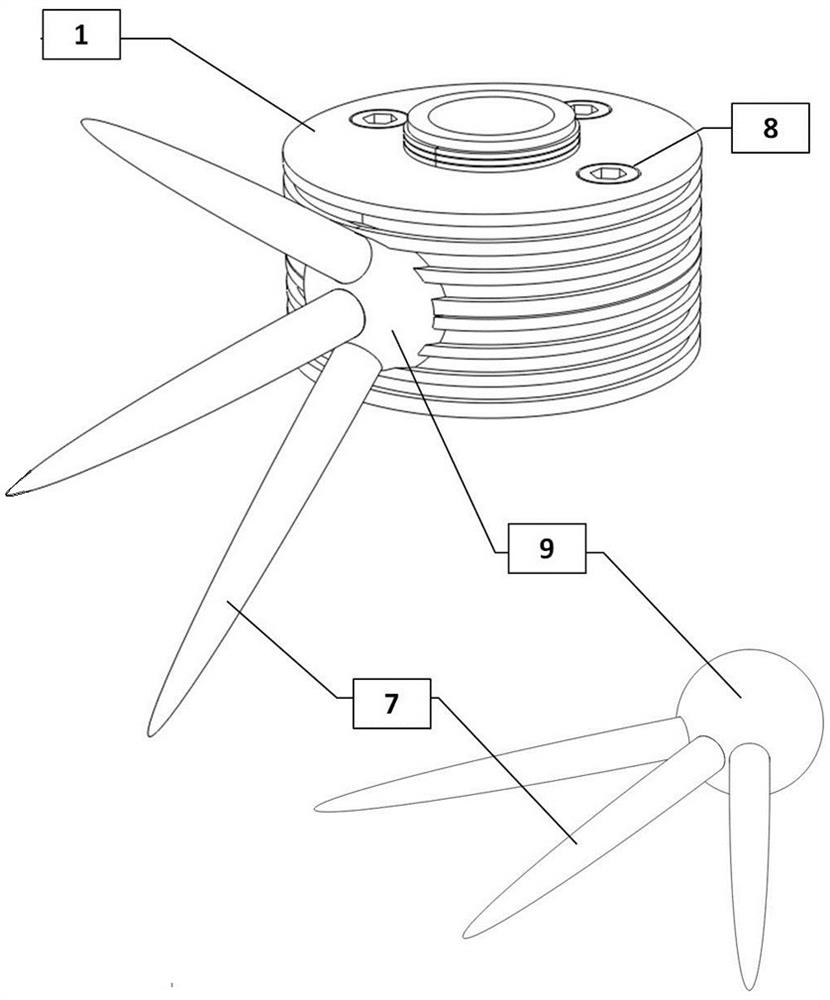

[0035] Such as figure 1 As shown, this combined 3D helical perforation simulation injection device includes that this combined 3D helical perforation simulation injection device can be composed of a certain number of parts with different functions, including joint part 1, connecting part 2, perforation Part 3, tail joint 4 four kinds. There is a sealing ring 5 at the upper end of each component, and a connecting hole at the lower end. The center hole corresponding to the sealing ring 5 at the top of each component has a male buckle, and the connecting hole has a female buckle, so that the parts can be connected end to end, which is convenient for disassembly and assembly. According to the perforation plan, they are connected to each other to form a combined 3D helical perforation simulation injection device. It can be poured into the artificial rock core for hydraulic fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com