Adjustable construction device for mining underground grooving

A construction device and adjustable technology, applied in safety devices, mining equipment, earth movers/shovels, etc., can solve problems such as hidden dangers, difficulty in determining ground porosity, inability to adjust the width of grooves, etc., and reduce service life. , the effect of increasing the slotting resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

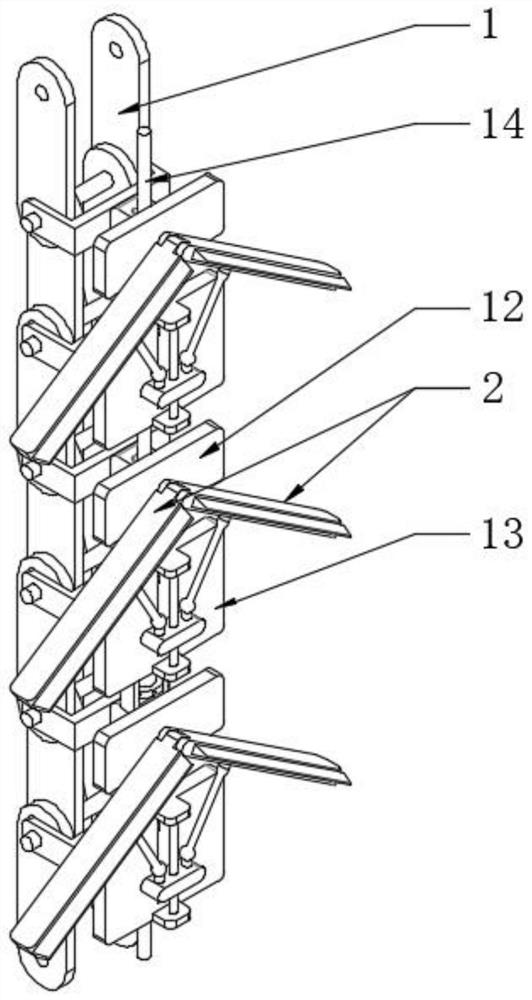

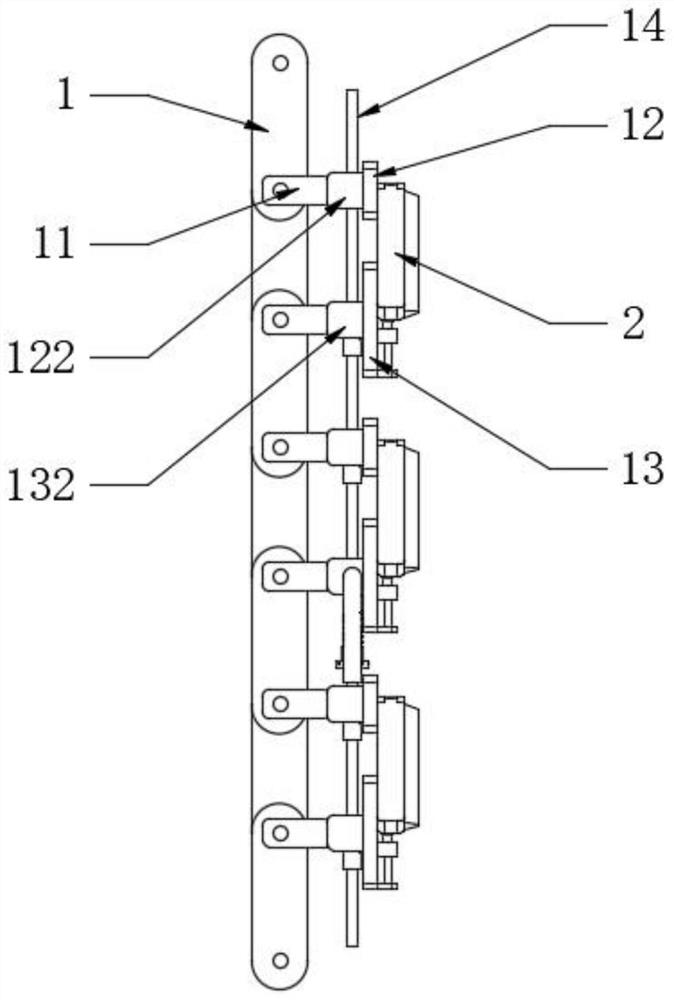

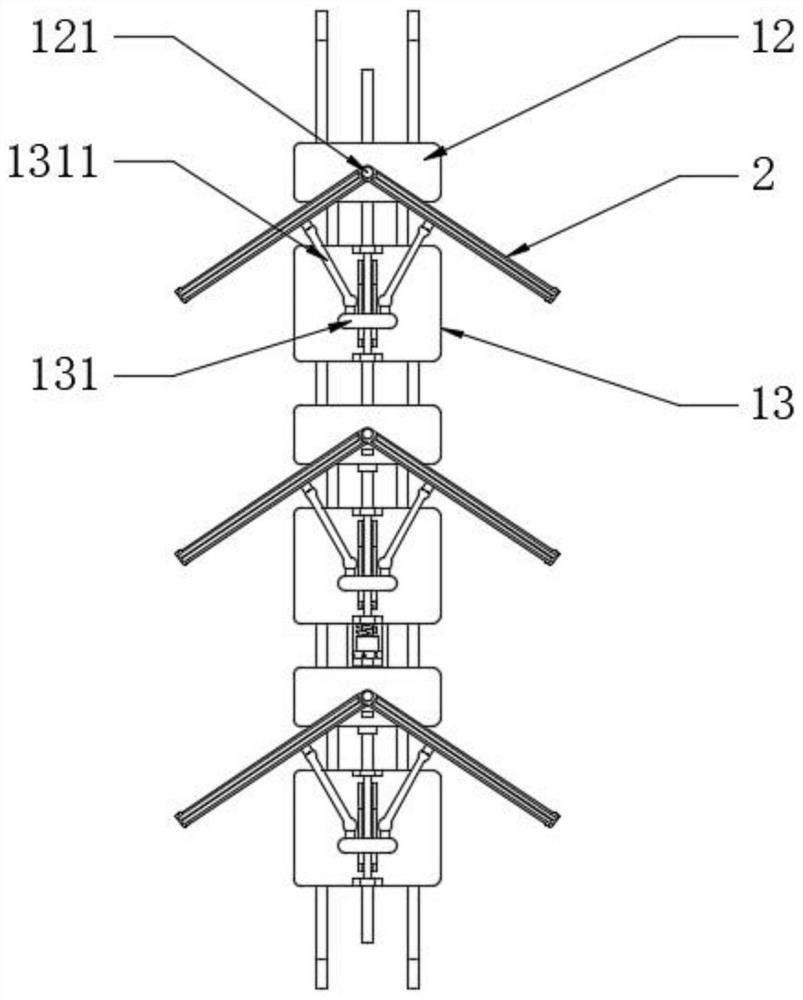

[0031] see Figure 1-5 , an adjustable construction device for digging underground mines, including a chain 1 and a scraper 2. In the prior art, the chain 1 is a fixed chain on a crawler belt, and the scraper 2 is arranged on the outer periphery of the chain 1 and is evenly distributed. In this embodiment, the two adjacent hinges on the chain 1 are all fixedly connected with the positioning plate 12 and the adjusting plate 13 through the movable connecting frame 11, and the positioning plate 12 and the adjusting plate 13 are distributed alternately; One side is fixedly provided with a rotary fixed shaft 121, the number of the scraper 2 is two and one end is connected with the rotary fixed shaft 121 in rotation, the side of the adjustment plate 13 away from the chain 1 is provided with a slider 131, one of the sliders 131 The sides are respectively connected to one side of the two scrapers 2 by two connecting rods 1311. When the slider 131 slides toward the direction of the pos...

Embodiment 2

[0033] see Image 6The difference from Example 1 is that a blade 4 is provided through one side of the scraper 2, and the blade 4 and the scraper 2 are vertically distributed. There are obstacles such as cement and gravel in the interior, which will not only increase the slotting resistance and reduce the service life, but also seriously affect the balance of the entire slotting equipment. By setting the blade plate 4 on the working surface of the scraper 2; the blade plate The blade edge on 4 faces the direction of movement of the scraper 2, which is convenient to squeeze into and cut obstacles, and reduce the resistance of digging; preferably, the rotary fixed shaft 121 is provided with an insertion rod 1211, and the axis of the insertion rod 1211 and The angle bisectors of the two scrapers 2 coincide and are elastically slidably connected to the rotary fixed shaft 121, and a tension spring can be sleeved on the insertion rod 1211. The plate 4 and the scraper 2 are rotation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com