Steel-ultra-high performance concrete combined bridge deck contraction weak constraint connecting structure and construction method thereof

An ultra-high-performance, steel bridge deck technology, applied in bridges, bridge parts, bridge construction, etc., can solve problems such as unstable changes in shrinkage effects, design effects of anti-shrinkage effects, and difficulty in accurate prediction, so as to facilitate quality control , The structural force transmission mechanism is clear and easy to design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

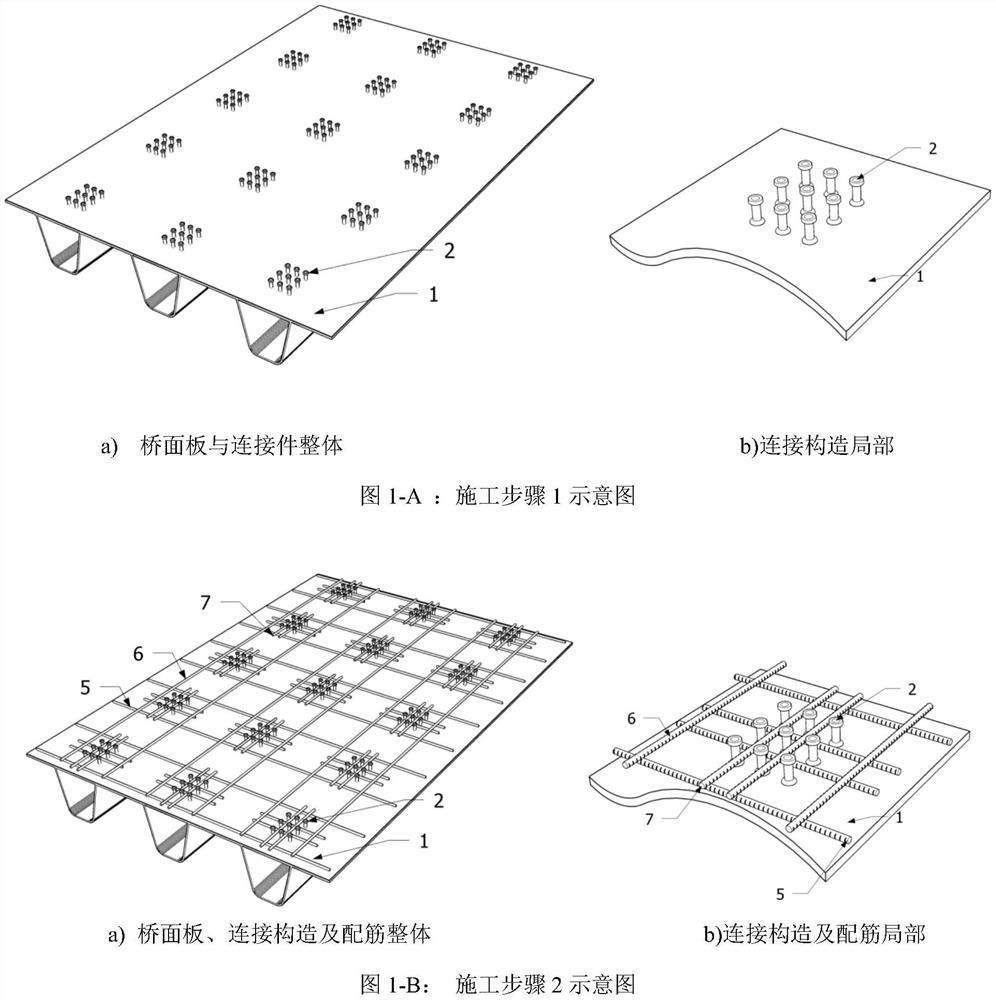

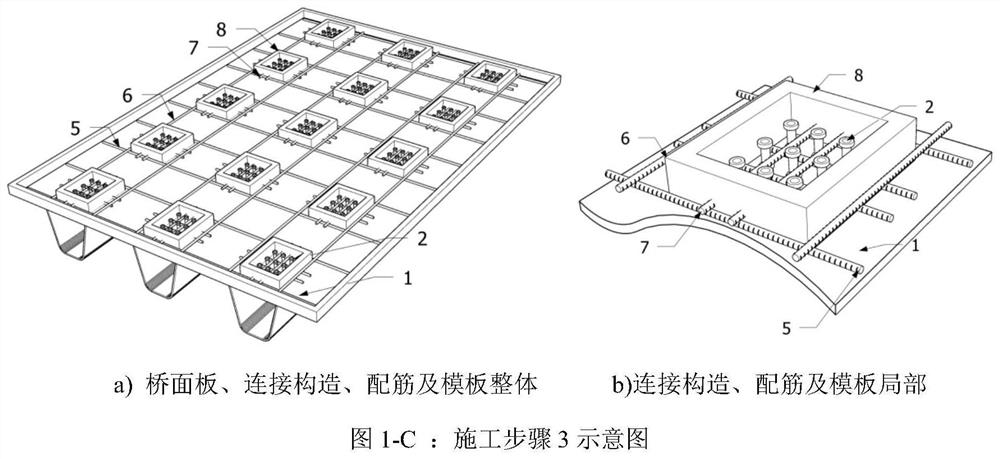

[0031] Such as figure 1 Shown:

[0032] A construction method for a steel-ultra-high performance concrete composite bridge deck connection structure, the steps of the method include the following steps:

[0033] 9) Weld several on the steel bridge deck 1 Stud group , form clusters, vertically and horizontally, and each stud group is composed of several studs 2. For example, but not limited, the stud group in this embodiment is formed by 3*3 studs 2; figure 1 -As shown in A;

[0034] 10) On the steel bridge deck 1, bind or weld the horizontal long steel bar 5, the longitudinal long steel bar 6 and the short steel bar 7, and form a horizontal long steel bar 5 and a longitudinal long steel bar 6 on the steel bridge deck 1. cluster framework , the welding stud group is just surrounded by the cluster frame; Vertical and horizontal short steel bars 7 ; said Vertical and horizontal short steel bars 7 interspersed with Welding stud Group Lap the individual studs within ...

Embodiment 2

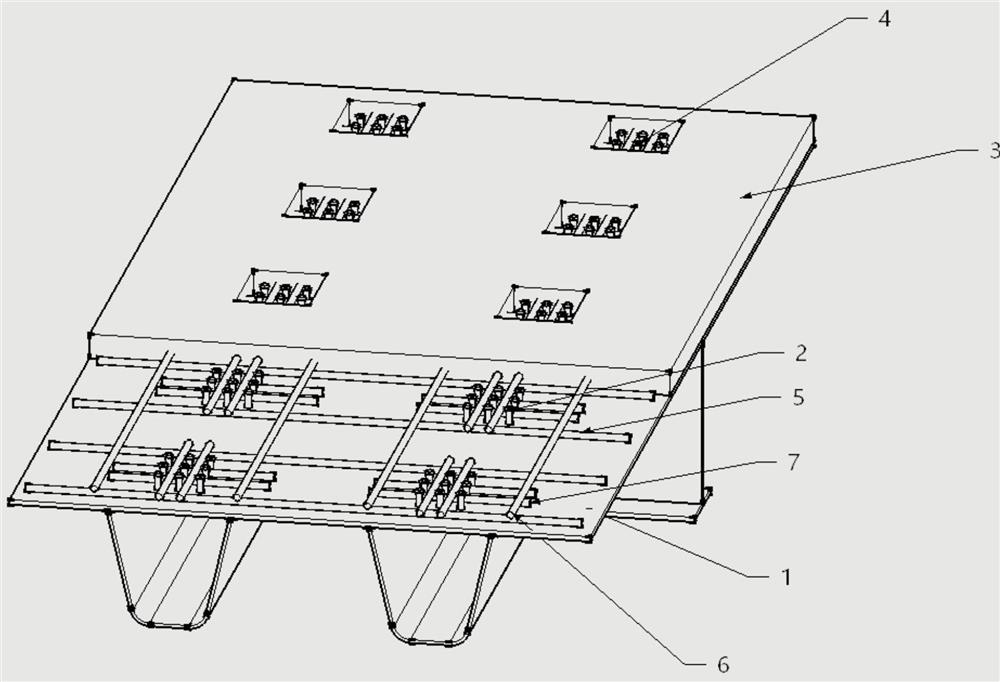

[0039] Such as figure 2 Shown:

[0040]The steel-ultra-high-performance concrete composite bridge deck obtained by the construction method disclosed in Example 1 is characterized in that it includes an orthotropic steel bridge deck and welding stud clusters, and the orthotropic steel bridge deck includes a steel bridge deck (1 ), orthotropic reinforcement network and ultra-high performance concrete layer (3);

[0041] The stud cluster is composed of several Stud group Each welding stud group is composed of several welding studs (2), and the welding studs are clustered and arranged on the steel bridge deck (1);

[0042] The orthotropic reinforcement network is configured with a single-layer reinforcement mesh inside the ultra-high performance concrete layer (3), including transverse reinforcement (5), longitudinal reinforcement (6) and vertical and horizontal short reinforcement (7), vertical and horizontal The short bars (7) are arranged on the welding stud cluster; the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com