A drying machine for small bread production

The technology of a dryer and a drying mechanism, which is applied in the field of small bread, can solve the problems of low work efficiency and low output, and achieve the effects of continuous output with a high degree of automation, high degree of automation, and increased output.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

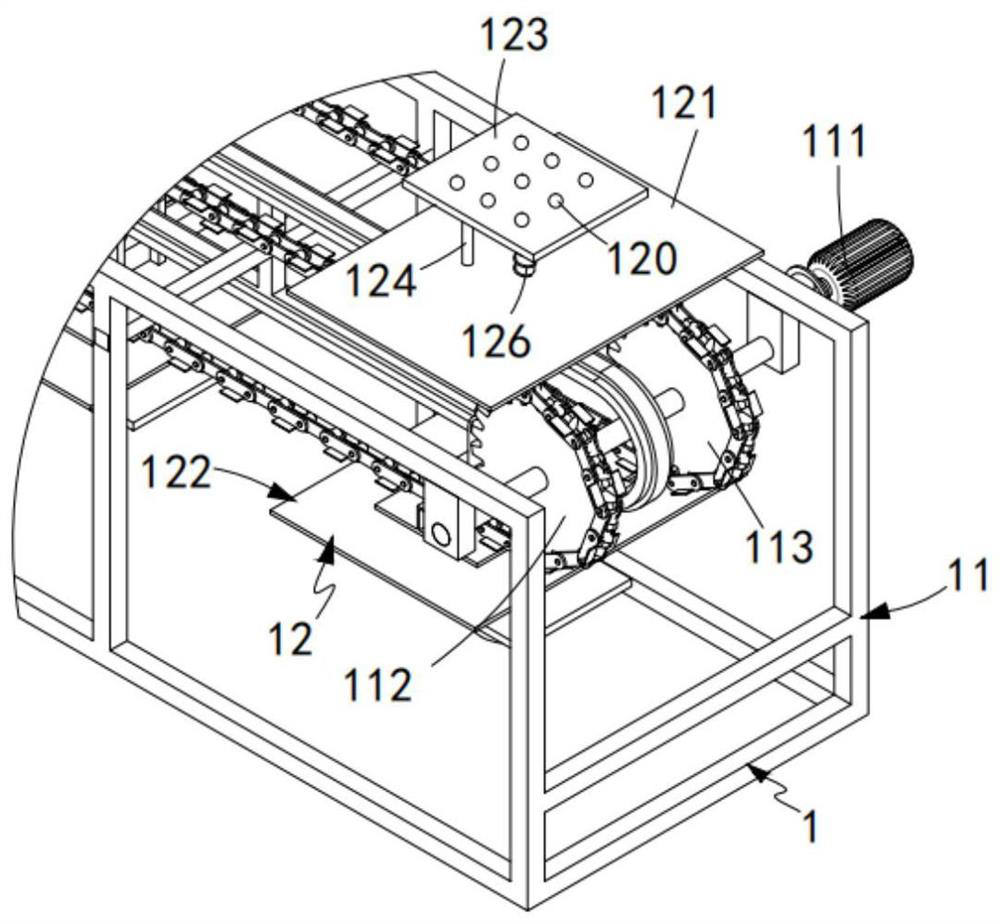

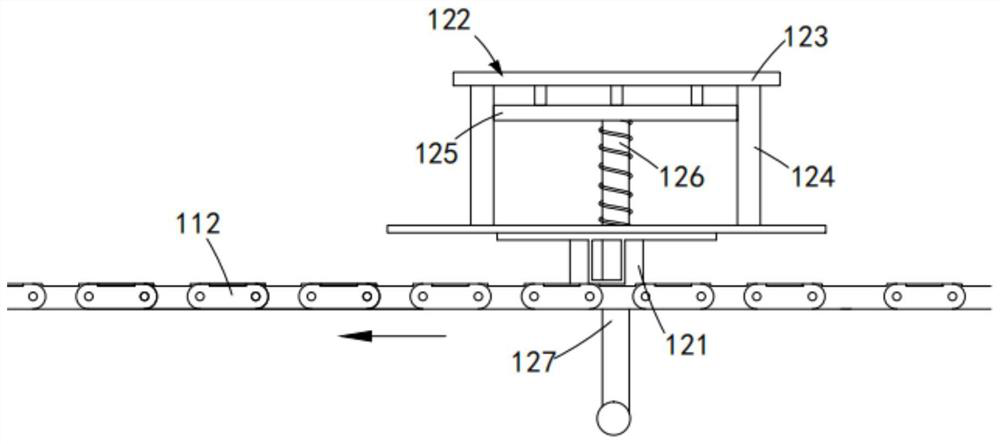

[0072] Such as figure 1 As shown, a drying machine for small bread production, including:

[0073] A transmission mechanism 1, the transmission mechanism 1 comprising a first transmission assembly 11 and several groups of bearing assemblies 12 equidistantly arranged on the first transmission assembly 11;

[0074] Drying mechanism 2, the drying mechanism 2 includes a drying box 21 sleeved outside the transmission mechanism 1, a positioning assembly 22 arranged at the input end of the drying box 21, and a positioning assembly 22 arranged in the drying box 21 And the first sub-assembly 23 for lateral sub-assembly, two sets of clamping assemblies 24 symmetrically arranged on both sides of the sub-assembly, and the clamping assembly 24 arranged outside the drying box 21 and cooperating with the clamping assembly 24 The second sub-assembly 25 for longitudinal sub-division work;

[0075] Injection mechanism 3, which is arranged outside the drying box 21 and arranged behind the dryi...

Embodiment 2

[0115] Such as Figure 17 As shown, the components that are the same as or corresponding to those in the first embodiment are marked with the corresponding reference numerals in the first embodiment. For the sake of simplicity, only the differences from the first embodiment will be described below. The difference between this embodiment two and embodiment one is:

[0116] further, such as Figure 17 As shown, the center injection mechanism 3 includes an injection assembly 31 intermittently connected to the clamping assembly 24 and a rotating assembly 32 for driving the injection assembly 31 to perform centrifugal spraying;

[0117] The spraying assembly 31 includes a connecting pipe 311 arranged on the support plate 2424 with a magnetic connection end, a jam box 312 arranged on one side of the second transmission assembly 241 and communicating with the jam box 312 The hose 313, the electromagnetic ring 314 sleeved at the end of the hose 313, the electromagnetic ring 314 is s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com