Telescopic flexible OLED lighting device and preparation method thereof

A lighting device and flexible technology, which is applied in semiconductor/solid-state device manufacturing, electric solid-state devices, semiconductor devices, etc., can solve the problems of not having stretchability, etc., and achieve excellent scalability and the effect of increased stretching rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

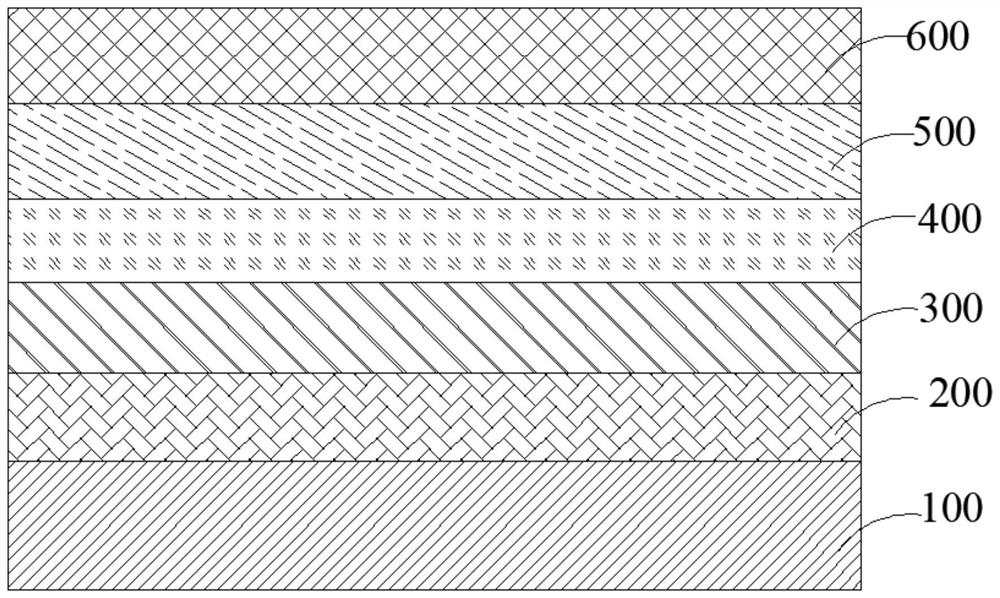

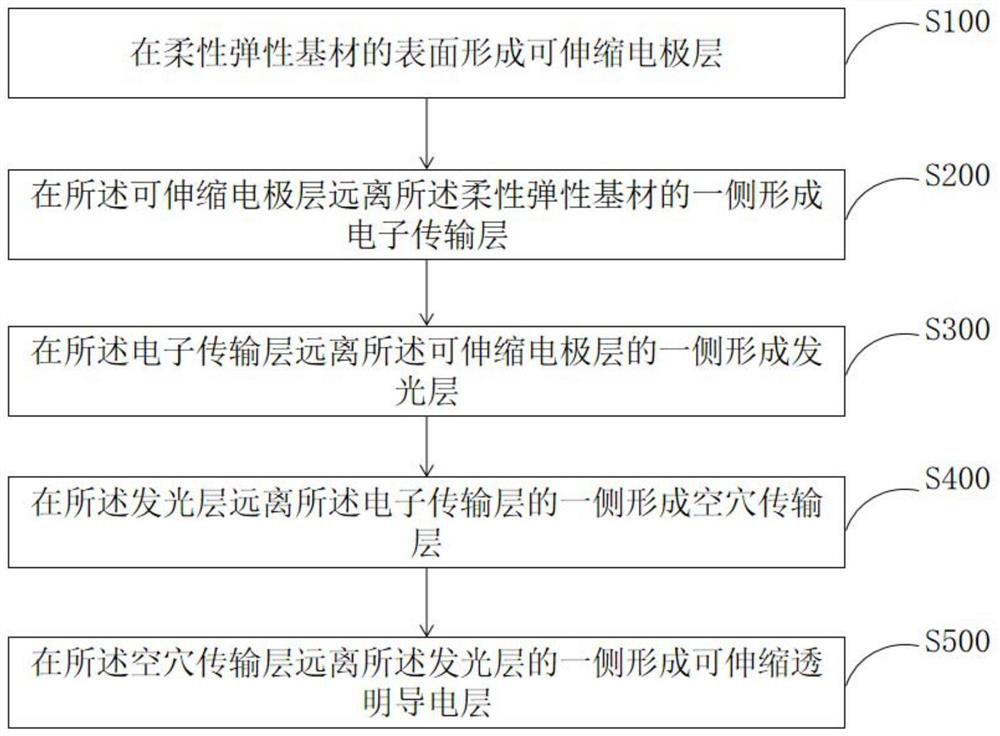

[0066] The present invention also provides the preparation method of the above-mentioned stretchable flexible OLED lighting device, such as figure 2 Shown, described preparation method comprises the following steps:

[0067] S100, forming a stretchable electrode layer on the surface of the flexible elastic substrate

[0068] According to an embodiment of the present invention, the preparation method of step S100 is any one of slit coating method, doctor blade coating method, screen printing method, spray coating method, and micro-gravure coating method.

[0069] Specifically, in step S100 , the metal paste is coated on the surface of the flexible elastic substrate 100 , dried and solidified to obtain the stretchable electrode layer 200 .

[0070] Further, forming the metal slurry includes: mixing the elastic polymer with a dispersant to form the elastic polymer slurry, and then adding the metal sheet into the elastic polymer slurry to form the metal slurry.

[0071] S200, f...

Embodiment 1

[0095] Step 1: Prepare silver paste.

[0096] First add PDMS to ethyl acetate, then stir and disperse to form PDMS slurry; then add silver flakes to PDMS slurry, stir evenly to form silver slurry. The weight percentages of silver flakes, PDMS and ethyl acetate in the silver paste were 50%, 25% and 25%, respectively.

[0097] Step 2: Fabricate a stretchable flexible OLED lighting device.

[0098] 50μm TPU is selected as the flexible elastic substrate, and a layer of stretchable electrode layer with a thickness of 0.1μm is prepared by coating silver paste on its surface. The stretchable electrode layer still has conductivity in the stretched state, and the stretchable electrode layer The elongation ratio of the layer is 5%-20%; then the ethanol solution of TIPD is sprayed on its surface to prepare a 50nm electron transport layer; then the toluene solution of SY-PPV is scraped on its surface to prepare a layer of 75nm thick Light-emitting layer; then adopt micro-gravure coating...

Embodiment 2

[0100] The first step: prepare aluminum paste.

[0101] First add PVA to amyl alcohol, then stir and disperse to form a PVA slurry; then add aluminum flakes to the PVA slurry, stir evenly to form an aluminum slurry. The weight percentages of aluminum flakes, PVA and amyl alcohol in the aluminum paste are 75%, 10% and 15% respectively.

[0102] Step 2: Fabricate a stretchable flexible OLED lighting device.

[0103] A 12 μm non-woven fabric is selected as the flexible elastic substrate, and aluminum paste is coated on its surface to prepare a stretchable electrode layer with a thickness of 0.5 μm. The stretchable electrode layer is still conductive in the stretched state, and can The stretching ratio of the stretchable electrode layer is 5%-20%; then spraying an ethanol solution of TPBi on its surface to prepare a 10nm electron transport layer; then scraping the surface to prepare a layer of toluene solution with a thickness of 50nm light-emitting layer; then use microgravure ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com