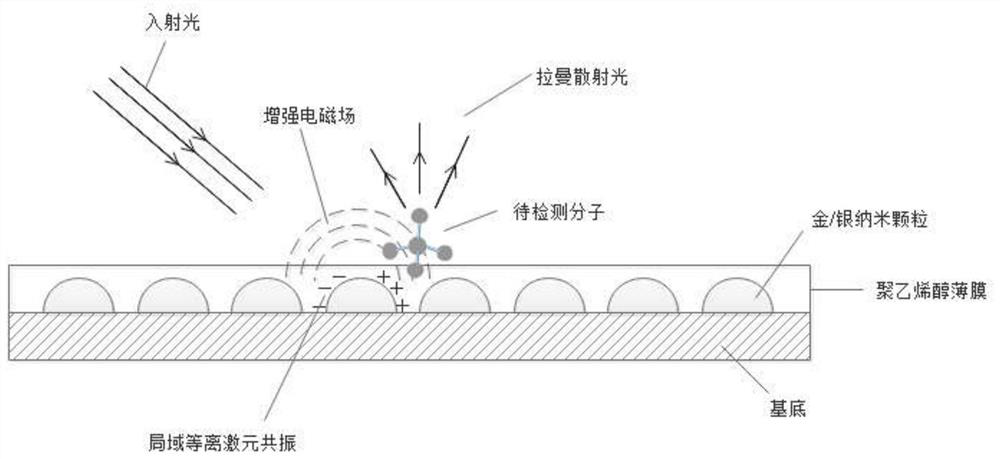

Polyvinyl alcohol-coated surface-enhanced Raman scattering substrate and preparation method thereof

A surface-enhanced Raman and polyvinyl alcohol technology, applied in the field of materials, can solve the problems of lower detection limit, inability to quench fluorescence, and difficulty in adsorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

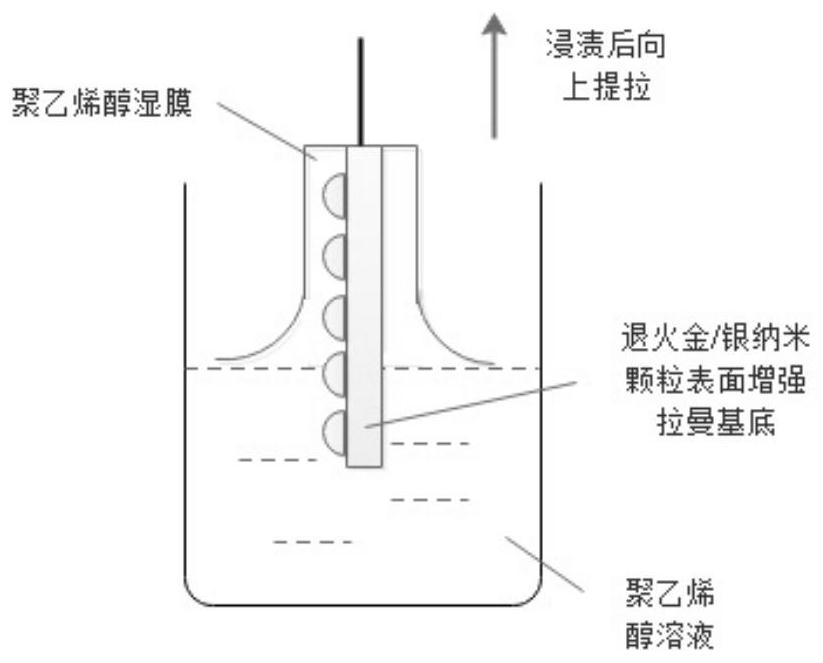

[0046] like figure 2 As shown, the method of coating polyvinyl alcohol by dipping and pulling coating includes the following steps:

[0047] (1) Prepare a high-temperature-resistant SG3 high-purity quartz plate with a size of 10mm×10mm×1mm, ultrasonically clean it with alcohol and pure water for 10 minutes, and then dry it in an oven at 95 degrees Celsius.

[0048] (2) The quartz sheet is placed in an ion sputtering coating machine, and a silver film about 10 nanometers thick is sputtered on the quartz sheet.

[0049] (3) Place the quartz sheet sputtered with a silver film in a vacuum rapid annealing furnace, rapidly raise the temperature to 900 degrees Celsius at a rate of 25 degrees Celsius per second, and naturally cool down to room temperature (20 degrees Celsius) after keeping the temperature for 5 minutes, and take it out to obtain annealing Silver nanoparticles substrate.

[0050] (4) Weigh 0.5 g of polyvinyl alcohol, pour it into 300 ml of pure water, heat to 95 deg...

Embodiment 2

[0054] like figure 2 As shown, the method of coating polyvinyl alcohol by dipping and pulling coating includes the following steps:

[0055] (1) Prepare a high-temperature-resistant SG3 high-purity quartz plate with a size of 10mm×10mm×1mm, ultrasonically clean it with alcohol and pure water for 10 minutes, and then dry it in an oven at 95 degrees Celsius.

[0056] (2) The quartz sheet is placed in an ion sputtering coating machine, and a gold film about 5 nanometers thick is sputtered on the quartz sheet.

[0057] (3) Place the quartz plate sputtered with a gold film in a vacuum rapid annealing furnace, rapidly raise the temperature to 900 degrees Celsius at a rate of 25 degrees Celsius per second, and naturally cool down to room temperature (20 degrees Celsius) after keeping the temperature for 5 minutes, and take it out to obtain annealed Gold nanoparticle substrate.

[0058] (4) Weigh 0.5 g of polyvinyl alcohol, pour it into 300 ml of pure water, heat to 95 degrees Cels...

Embodiment 3

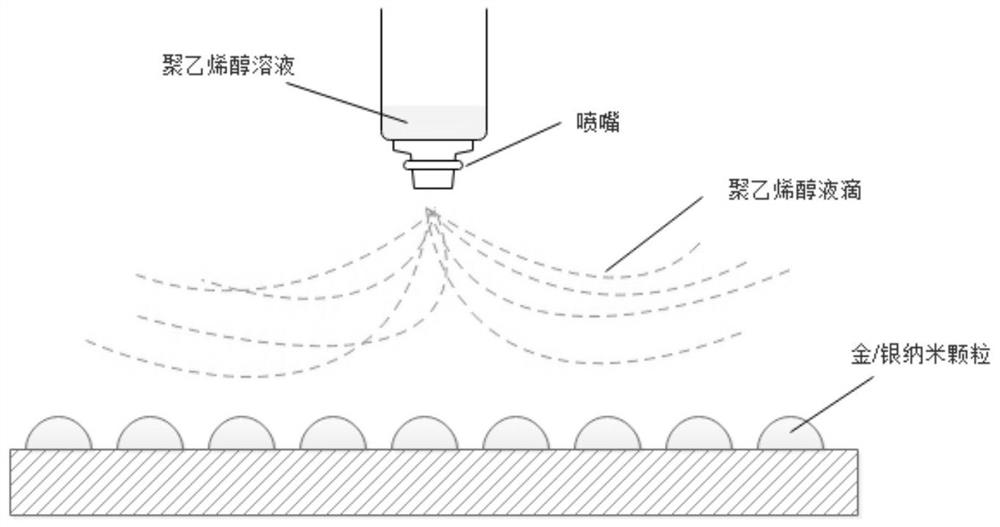

[0062] like image 3 As shown, the spin coating method is used to coat polyvinyl alcohol, including the following steps:

[0063] (1) Prepare a high-temperature-resistant silicon wafer with a size of 10mm×10mm×1mm, ultrasonically clean it with alcohol and pure water for 10 minutes, and then dry it in an oven at 95 degrees Celsius.

[0064] (2) The silicon wafer is placed in a magnetron sputtering coating machine, and a silver film about 10 nanometers thick is sputtered on the silicon wafer.

[0065] (3) Place the silicon wafer sputtered with a silver film in a vacuum rapid annealing furnace, rapidly raise the temperature to 900 degrees Celsius at a rate of 25 degrees Celsius per second, and naturally cool down to room temperature (20 degrees Celsius) after keeping the temperature for 5 minutes, and take it out to obtain annealing Silver nanoparticles substrate.

[0066] (4) Weigh 0.5 g of polyvinyl alcohol, pour it into 300 ml of pure water, heat to 95 degrees Celsius and co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com