Accurate pressurizing gluing clamp

A fixture and gluing technology, applied in the direction of material gluing, connecting components, preparation of test samples, etc., can solve the problems of high test cost, large pressure uncertainty, inability to know the pressure of parts, etc., to ensure the adhesion The effect of mass, avoiding overturning, and balancing the overall center of gravity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The precise pressurized adhesive fixture provided by the present invention will be explained below with reference to the accompanying drawings.

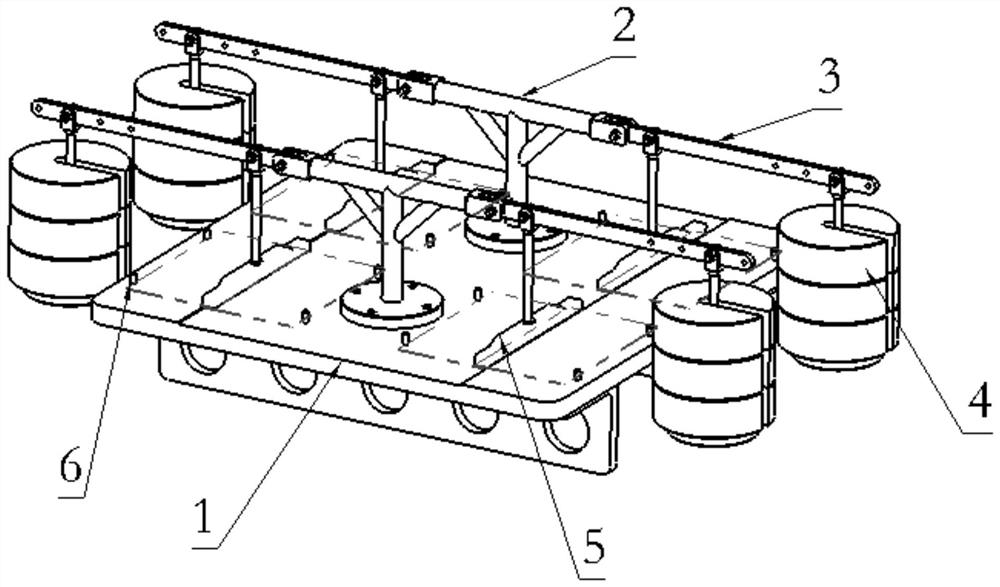

[0030] figure 1 For the structural representation of the precise pressurized gluing fixture provided by the present invention, refer to figure 1 , the present invention provides a precise pressurized adhesive fixture, comprising: a bottom plate 1 and a pressurizing mechanism; the pressurizing mechanism includes: a support pole 2, a pressurizing connecting rod 3, a counterweight 4 and a pressure block 5;

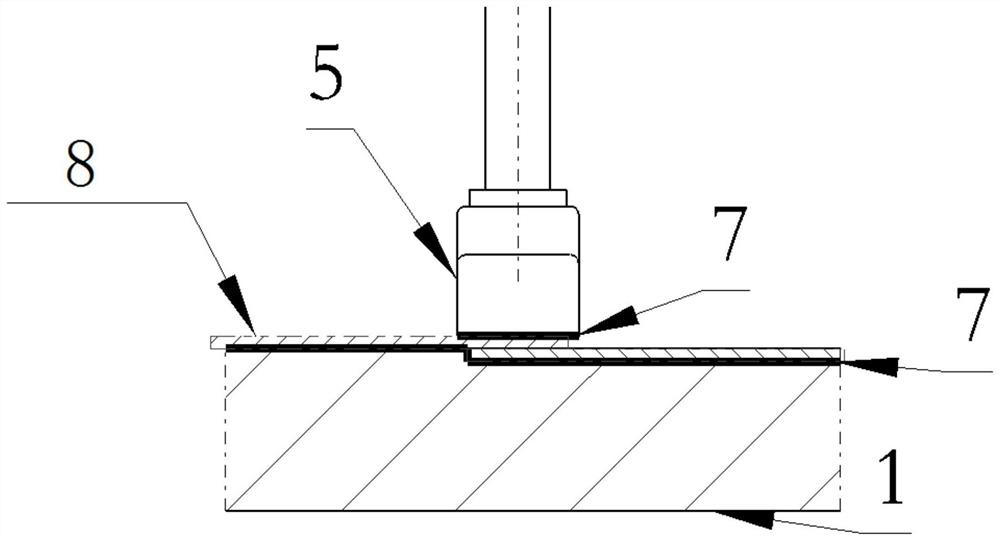

[0031] The lap shear test piece 8 is arranged on the base plate 1, and the pressure block 5 is arranged at the overlap of the lap shear test piece 8;

[0032] The support pole 2 is arranged on the base plate 1, the support pole 2 is T-shaped, and the two ends of the support pole 2 are connected with the pressurizing connecting rod 3;

[0033] One end of the pressurizing link 3 beyond the bottom plate 1 is provided with mult...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com