Food production weighing device capable of avoiding residual oil stains and using method thereof

A weighing device and food technology, applied in the direction of measuring device, weighing, weighing auxiliary equipment, etc., can solve the problems of increased labor intensity, moldy oily residue, consumption of human resources, etc., to reduce labor intensity, improve cleaning effect, Clean up the effect with ease

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

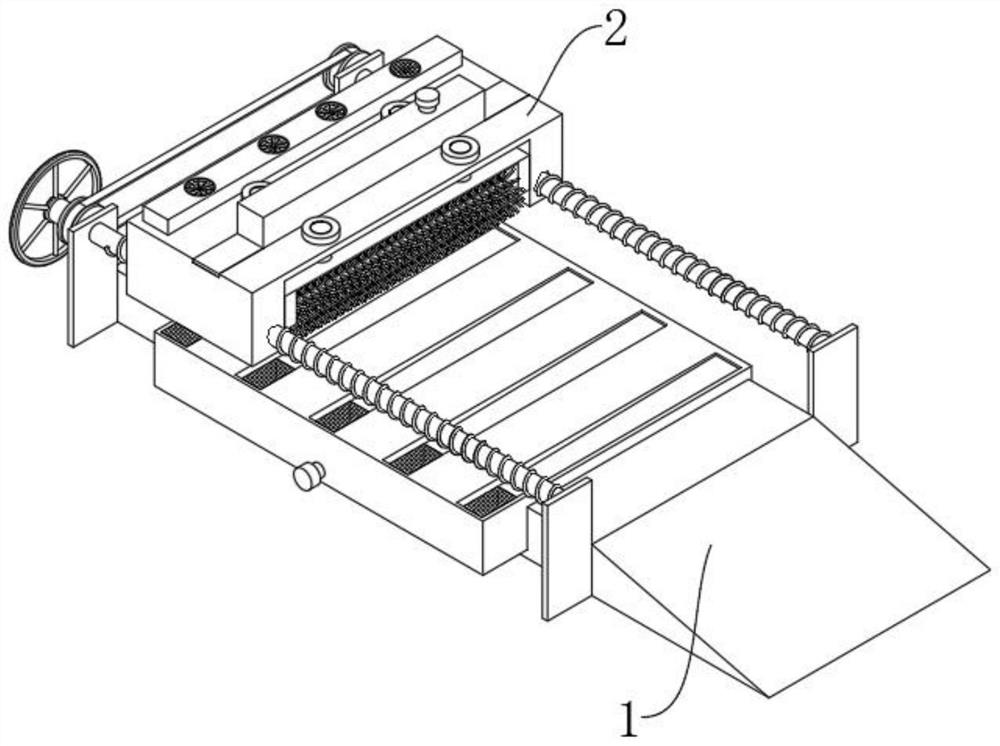

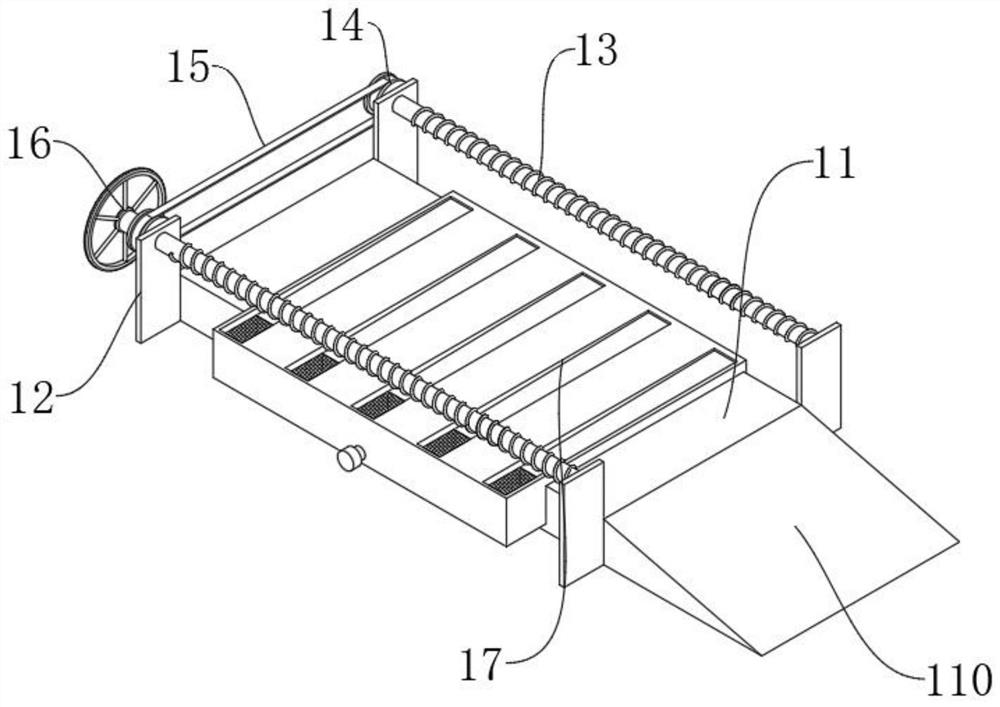

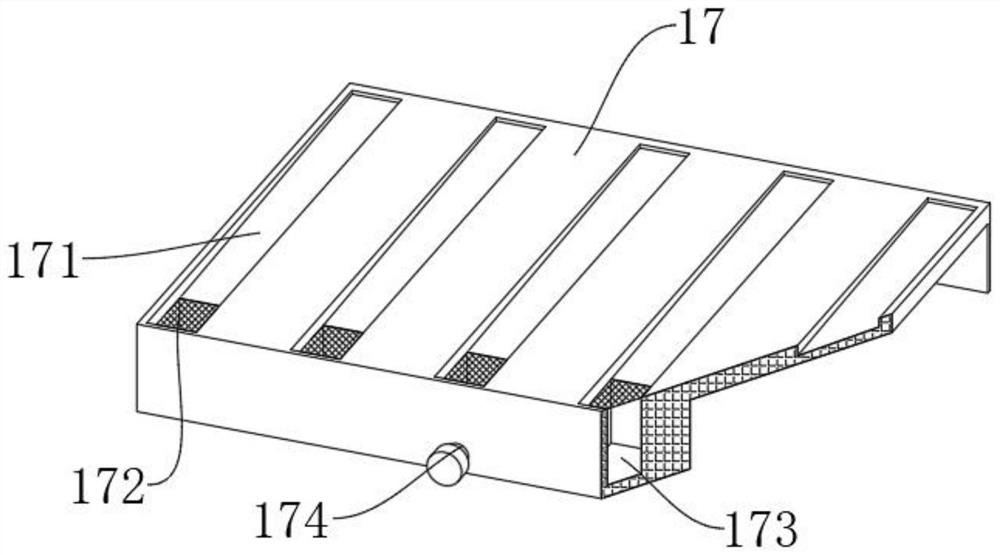

[0064] see Figure 1-Figure 11 As shown, the present embodiment provides a weighing device for food production that avoids residual oil stains, including a weighing device 1 and a cleaning device 2 above the weighing device 1. The weighing device 1 includes a weighing device 11, and the weighing device 11 is close to two The side wall of the end is provided with two connecting plates 12, and a screw mandrel 13 is arranged to rotate between the two connecting plates 12, and the cleaning device 2 is arranged on the outer wall of the screw mandrel 13, and the cleaning device 2 at least includes:

[0065] Support frame 21, the support frame 21 is an inverted "U" shape, the surface of the support frame 21 near the bottom is provided with a thread hole 211, the thread hole 211 is threadedly connected with the outer wall of the screw rod 13, and the top of the support frame 21 is arranged in sequence from front to back There are front holes 212, front slots 213, back holes 214 and ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com