Blast furnace gas bypass desulfurization method and device

A blast furnace gas and desulfurization device technology, which is applied in gas dust removal, combustible gas purification, gas pollutant removal and other directions, can solve problems such as the inability to meet ultra-low emission index requirements, and achieve good environmental benefits, economic benefits, and practicability strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

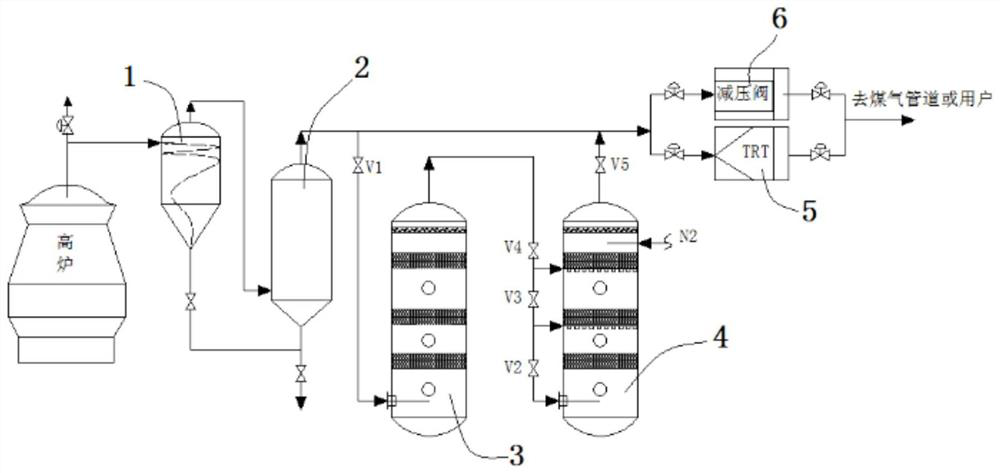

[0029] Such as figure 1 As shown, a blast furnace gas bypass desulfurization device includes a coarse dust collector 1, a fine dust collector 2, a hydrolysis catalytic tower 3 and a desulfurization tower 4, a rough dust collector 1, a fine dust collector 2, a hydrolysis catalytic tower 3 and a desulfurization tower 4 They are connected sequentially along the flow direction of the gas path.

Embodiment 2

[0031] Such as figure 1 As shown, the present embodiment is a further improvement on the basis of embodiment 1, specifically as follows:

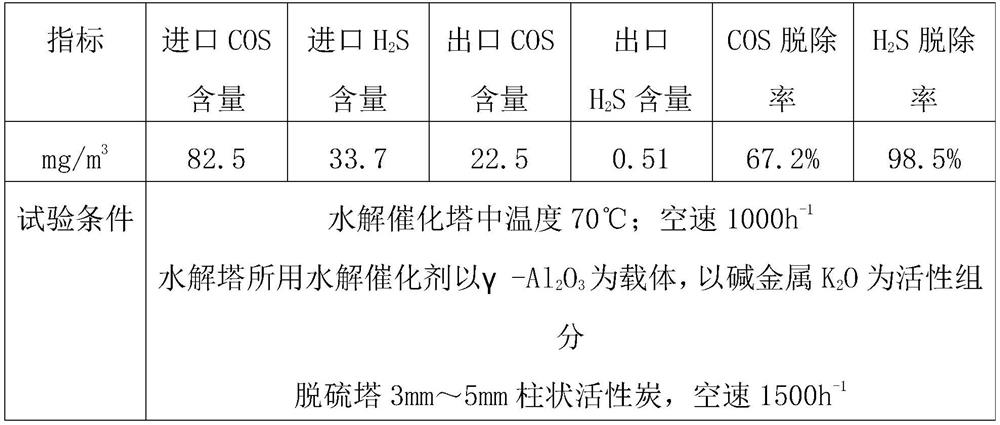

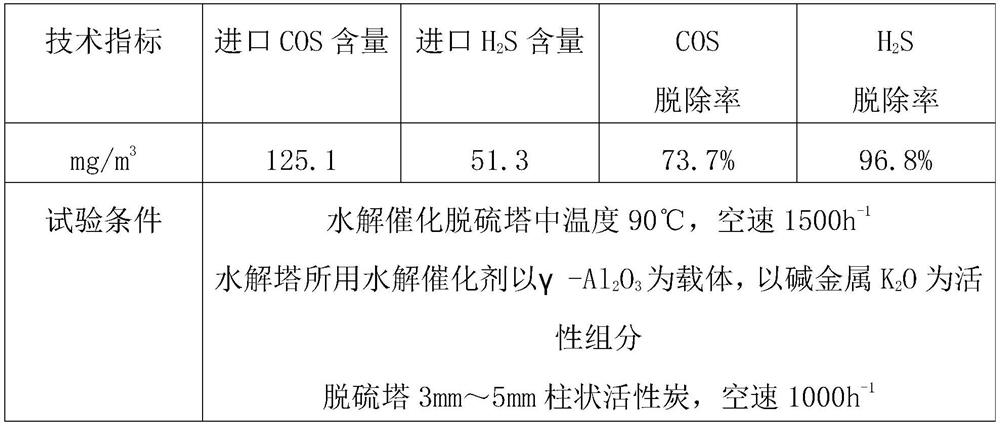

[0032] The hydrolysis catalyst used in the hydrolysis catalytic tower 3 is γ-Al 2 o 3 or TiO 2 or ZrO 2 As a carrier, alkali metal K 2 O is the active ingredient.

Embodiment 3

[0034] Such as figure 1 As shown, the present embodiment is a further improvement on the basis of embodiment 2, specifically as follows:

[0035] There are multiple supporting layers in the hydrolysis catalytic tower 3, on which the hydrolysis catalyst is placed, and the pressure drop of the filled bed layer is lower than 700 Pa. In addition, manholes are arranged on the hydrolysis catalytic tower 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com